Table of Contents

Size and Weight

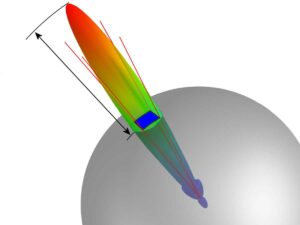

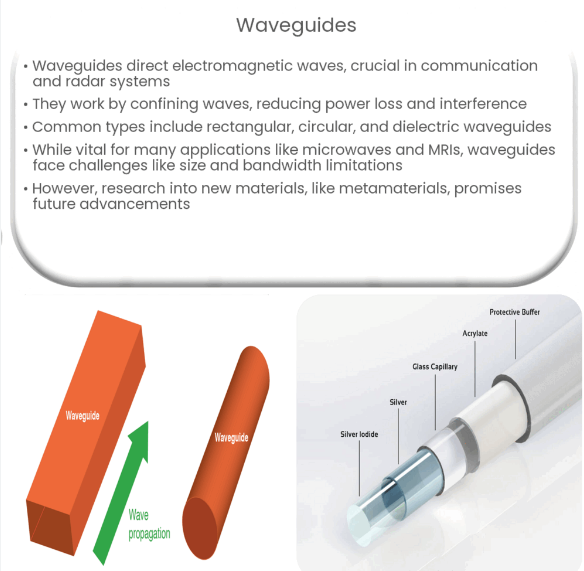

Waveguides are an important type of transportation of electromagnetic signals, especially at microwave frequencies. The transmission lines made of metals have many restrictions that result from their size and weight. The geometric magnitude of a waveguide is proportional to the frequency of length being transmitted, meaning that the physical dimensions of the waveguide are of the order of the wavelength of the frequency. For example, an often used waveguide in the technology of satellite transmission will have to perform at a frequency of about 10 GHz, i.e. the wavelength is 30 mm (Jackson 74). Thus the cross-sectional dimensions are of the order of more than half a millimeter or at least a millimeter or two. In many situations, waveguides must be one or two orders of magnitude larger than their width.

This weight entails greater material consumption and weight in relation to the structure. In the process of a spacecraft flight from the surface of the Earth to the desired orbiting Earth satellites, fuel consumption is an essential variable, and even a small increase in weight has significant consequences. Aluminum is considered one of the lightest metals, and even when it is made of a waveguide, the weight of the material made of copper or brass will grow significantly. A communication satellite loses the advantage of its cost in orbit if it has a large weight. Then it may be that the waveguide that attaches an antenna in satellite communication is a significant portion of the weight of the entire satellite. Installation in buildings based on the waveguide of a large and critical-sized wave has many adverse effects.

If the waveguide, for example, is attached to the outside of the wall, and must be properly restrained in this case and does not conserve well when it vibrates with the wind, the attachment must be very strong. In comparison, waveguides occupy far more room and need so much more than a physically small and fragile fiber throughout the rigid cables and buildings. The installation of bulky and serious wires in crowded urban conditions becomes excessively difficult and needs too much installation that is too expensive. For such causes, lighter and more pliable, such as tubular wires or fiber optic cables, are most commonly used than waveguides, although they have limitations. With the strong disadvantaging of the accompanying cables or the use of fiber optics in a much higher frequency, something like this must be deployed to keep costs as low as possible.

Complexity in Fabrication

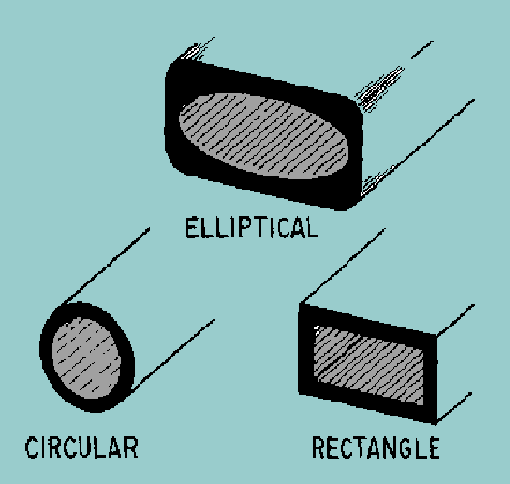

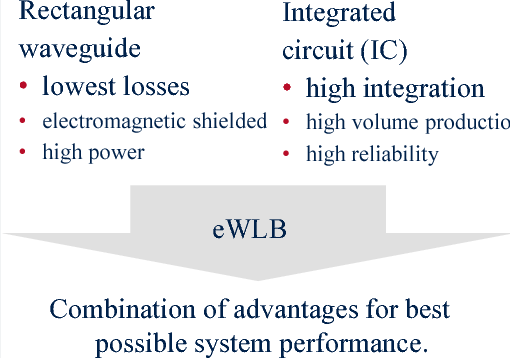

Waveguides are more difficult to produce compared to other communication mediums, translating to more testing required to ensure they function correctly. Common telecommunications waveguides must be manufactured with precision, as even with a seemingly simple rectangular cross-section for a 10 GHz operation, it must have a width of nearly 23 mm and a height above 10 mm with tolerances as low as 0.1 mm. It requires precision manufacturing over hundreds of meters lengths. Beyond the shape, the materials must be able to function in the aerospace and defense industries, where the waveguides are used for radars and satellite communications. As such, the waveguides designed for electronic systems must be mined, shaped, and molded with accuracy.

The requirements necessitate the use of high-grade copper or silver and milled with equally high precision and accuracy. With copper and silver being both expensive and hard to work with, the overall costs of such waveguides are high, though materials constitute a relatively small portion of the cost. Manufacturing of waveguides is also hindered by the requirement of specialized machinery for the precision cutting and milling and CNC machines for their construction. Finally, assembling the waveguide also requires expensive equipment and clean-room environments, and the need for some training cannot be understated.

On the other hand, other communication mediums require less care in their manufacture. For example, more modern optical fibers are created by drawing glass or plastic to increasingly lower diameters, with the drawn filaments being more flexible and therefore lighter. Finally, the cost of laying optical fiber cables are also similar to other telecommunication cables, if not lower. The production of waveguides is more expensive as there are material costs, machinery for its milling and cutting, and minimal costs in the creation of the more straightforward oscilloscope readouts and waveguides in comparison.

Limited Frequency Bandwidth

Waveguides are efficient within a limited frequency range, which is mostly determined by their geometry. These confinement effects may be both positive and negative, in that while the waveguide frequency – bandwidth – is limited, long-range propagation of modes inside it is sustainable. It is normally a disadvantage, however, as, in practical applications, a wide frequency spectrum of both transmission and reception is needed. For example, a standard espresso rectangular waveguide for X-band radar systems works within the frequency of 8 – 12 GHz. It is important to note that the waveguide will not operate perfectly out of these frequencies – a cutoff occurrence will take place, where the transmission is blocked or severely limited.

It vastly limits the range of applications, as the bandwidth is so limited that only those applications where these specific frequencies are transmitted are practical. Coaxial cables and fiber optics, being the main alternative to waveguides in signal transfer and receiving, can carry a much wider range of frequencies. Coaxial cables can operate within a frequency range of kHz within low frequency range to GHz in high-frequency, and are wildly used in home electronics and broadband. Fiber optics, on the other hand, may operate miles of a terahertz frequency range and have virtually unlimited bandwidth. Waveguides thus cannot be utilized in cases of high data transfer, such as HD video streaming or ultrafast Internet access.

Apart from these limitations, it also limits system flexibility and leads to the increased cost of using wider bandwidth alternatives. For example, deploying waveguides in an urban communication network would limit its ability to adapt to new technological changes, as changes of the frequency range in which data frequencies will incur would require the expensive method of waveguide change. There are many instances of waveguide use in intricate systems, such as satellite communication systems, to which a limited range of waveguide components can correspond. As a result, their design tailoring for a precise frequency requires, as was out, specially designed waveguide, which adds to the cost and sometimes render some systems infeasible due to prospective costs and raise the system’s budget.

Mode Dispersion

Mode dispersion in waveguides is the phenomenon leading to the distinction that different modes with which the wave is propagated are spreading at different rates. It creates a host of problems in systems that require pinpoint accuracy of signal arrival continuity. For instance, in telecommunications, if the waveguide is carrying the signal over large distances, the delay between modes is long enough to cause excitation of lower rates. Therefore, the signal will be distorted and about the rest of the data integrity for the piece is lost. Meanwhile, single-mode fiber optics mostly adhere to the rule that only one mode can be carried.

This negates the effect of mode dispersion, and the results are more competent transmission. In the fiber optic, the light travels straight on the path with minimal reflection and hence loss so that data can be sent further and faster. The impact on such is profound, especially in the practice of broadband communication systems. Here, the signal must always be retained as clear as possible, and the timing must be correct. Meanwhile, on a given multimode waveguide, the delay between the fastest and the slowest modes transmitted can be of the order of nanoseconds per meter. Over a link distance of a few kilometers, the difference of the phase of the signal is orders of magnitude magnitude greater.

Thus it is much more difficult to reconstruct the initial data due to the programming properties of the signal. Engineers have acknowledged this and realize one way to combat this is by using only single-mode waveguides. However, they require more stringent requirements for source light purity and alignment, so even the best quality of these waveguides can generate some dispersion. Due to this, great attention must be paid to production and assembly, raising the cost of the system.

Losses

Waveguides demonstrate effective transmission of high frequency, but such technology has some inherent losses, which impacts its efficiency in some applications. The primary types of power losses are dielectric, caused by the absorbed energy by the waveguide material, dielectric, induced by the properties of the insulating material, and waveguide losses, related to inefficiencies of the waveguide as the structure. Dielectric losses describe the power absorbed by the waveguide itself. As a rule, a certain material, in this case, Teflon, is used for insulation and guiding of the electromagnetic wave through the waveguide.

Teflon has a low but not zero loss tangent, equal to 0.0002 at microwave frequencies. In this case, the loss tangent means that every unit of wave distance, such as centimeter or inch, lost certain fraction of the power of the wave, thus attenuating it. Metal losses are caused by the phenomenon of the skin effect, describing how with alternating currents, the electrons usually move near the surface of the conductor. As waveguides are typically made of metals, such as copper or aluminum, the effect has significant impact as even high-quality metals have resistance at extremely high frequencies, which waveguides are used for.

Thus, the signal loses power in the form of heat, decreasing and weakening the transmitted signal. Losses associated with power are caused by some imbalance or imperfections of the waveguide as structure, which both cause scattering of the wave and, consequently, another type of attenuation. In comparison, optical fibers demonstrate significantly lower loss rates, which allows their uses. The losses of typical single mode fiber equal to 0.2 dB per kilometer, than that of highly efficient and perfectly constructed waveguides with losses several times higher per kilometer.

Flexibility

Introduction One of the main characteristics of the waveguides that makes them less practical than other media of transmission in various applications is the rigidity. Even though this feature is determined by their geometry and is what makes one of the fundamental properties of waveguides – having a fixed shape and size, unlike, for example, radiant cables – it severely limits their usage in the field. The majority of waveguides are made of rigid materials such as copper or aluminum, and they cannot bend over a significant angle – even if it was possible to accomplish without bending of the measured signal, the whole structure would become essentially unusable in these cases as waveguides allocated for optical and other types of transmission would become trapped inside the cavities of the structure, and deflective changes of its radius would result in a destruction of the signal.

This, in turn, creates a number of challenges and issues faced during installation and maintenance, some of them being the subject of the current paper. Inefficiency Because of the peculiarities of waveguide design, the issues mainly concern the easiness and convenience of installations and do not make them unsuitable for the abovementioned applications completely. In particular, in cases where the infrastructure is built or maintained in central urban regions and inside buildings, the process of deployment can become significantly more difficult and costly due to the structure rigidity. This is especially noticeable in the case of having to fit the waveguide in a substantially limited space or having to avoid obstacles during transportation and installation.

In the given case, waveguides lose to radiant cables, which are more flexible and can be routinely laid into various cavities regardless of the overally structure rigidity. For these reasons, many designers use optic cables that, being significantly smaller, also possess the capability of bending with nearly no ramifications. Indeed, a typical third of a millimeter diameter optical fiber can bend with the radius of a few centimeters without suffering any radiation and performance loss, while even the most flexible waveguide would lose a noticeable part of the signal when shaped similarly and would risk itself being damaged.

Furthermore, the reasonably limited but existent capability of these waveguides to bend makes them still inferior to coaster cables or irradiated tubes, which can be effortlessly shaped to conform to any surface or to avoid obstacles. Cost On the other hand, the very issue of waveguides being rigid creates a problem in that resolving it – and, effectively, creating a useful transmission medium from a flexible waveguide – requires significantly higher production and processing costs that would eventually affect the cost of the communication system in general. Thus, flexible waveguides do exist and used on some occasions, but due to their other losses in terms of performance and usability and the necessities of their manufacture, they tend to be significantly less effective than the alternatives, being heavier and more cumbersome and, consequently, more problematic in transportation and installation.

Susceptibility to Interferenc

Waveguides are highly prone to interference in many forms, due to their structural nature and the specificities of their operation. The first form of known interference, caused by electromagnetic radiation, could manifest itself as a significant source of interference in areas with high levels of RF activity. With multiple industrial applications powered by heavy machinery with high levels of RF leakage, as well as ongoing manufacturing operations, industrial environments that use waveguide communication are a likely target for this type of interference. Even in urban environments, the cross-talk from nearby telecommunications networks could interfere with the waveguide-based communication lines, making the increase of EMI protection a priority when using this method of communication.

A second type of interference is likely to appear in the cases of leaking waveguides: if not properly sealed, the waveguide’s structure could function as a source of interference itself, while also being susceptible to external influences. More complex types of waveguides, particularly the installations that do not share a single geometry and are separated into multiple smaller pipe-like structures, can also leak additional signals, contaminating those that are transmitted. This is particularly likely in high-traffic areas, where many smaller waveguide lines are installed closely, and are likely to cross over in significant impedance, leading to a form of crosstalk.

One way in which waveguides could be protected from outside interference is by means of waveguides with stronger impedance mismatch – however, this is significantly less efficient than using either coaxial or shielded twisted pair, which are not susceptible to interference. Both coaxial cables and shielded twisted pair cables are completely shielded from outside interference, and possess additional layers of shielding, protecting them from environmental interference. For example, Cat6a standard of shielded twisted pair utilizes a particularly strong form of shielding which protects the wire in question from the interference even after it leaves the main UTP, or unshielded twisted pair, housing.

A standard coaxial cable, on the other hand, has a metal shield protecting the inner conductor. This shield results in the coaxial cable being impermeable to outside EMI, which has no effect on the signals moving through it – this shield has the secondary function of preventing any form of crosstalk, or data leaking, with the surrounding environment, further securing the integrity of data transmission signals. This also ensures the excellent performance of the cable even in highly populated urban environment. In comparison, waveguide installations have a requirement for expensive elaborate shielding implementations, which can be highly difficult to design, implement, and manufacture. For example, a common shielding installation is embedding the waveguides in metallic enclosures. This simple shielding method, however, adds significant weight and construction line cost to the installation, which are high enough without this additional cost for large-scale installations.