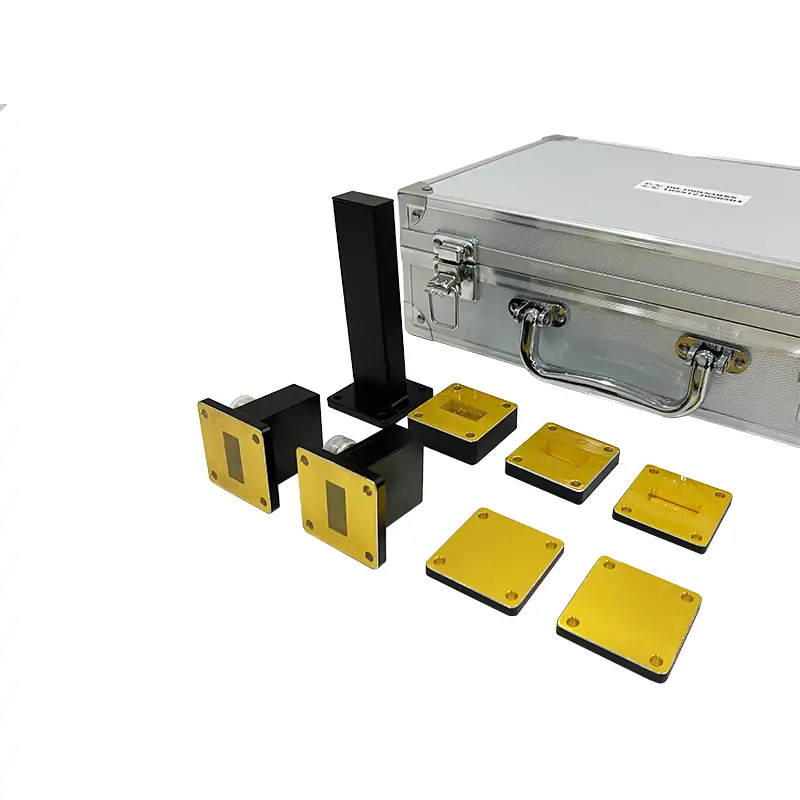

Waveguide Shorts/Shorting Plates

Waveguide shorts, or shorting plates, are components used to reflect microwave signals within a waveguide system, effectively terminating the waveguide in its characteristic impedance. They are crucial for testing, measurements, and system calibration, providing a precise method for creating a known reflection point in microwave and RF applications.

Dolph Microwave excels in the design and manufacture of high-quality waveguide shorts and shorting plates, crucial for creating high-reflection short circuits in waveguide systems. These components are essential for precise signal termination, ensuring optimal performance across a wide range of microwave and RF applications. With compatibility from WR2300 to WR10, our waveguide shorts are suitable for all standard waveguides, offering versatility and reliability for engineers and technicians alike.

Key Features

Broad Frequency Operation

- Frequency Range: Designed to operate from 0.32 to 112 GHz, accommodating a wide spectrum of applications and system requirements.

Exceptional VSWR

- Minimum VSWR: Achieving a minimum Voltage Standing Wave Ratio (VSWR) of 60, indicative of high-quality signal reflection and termination.

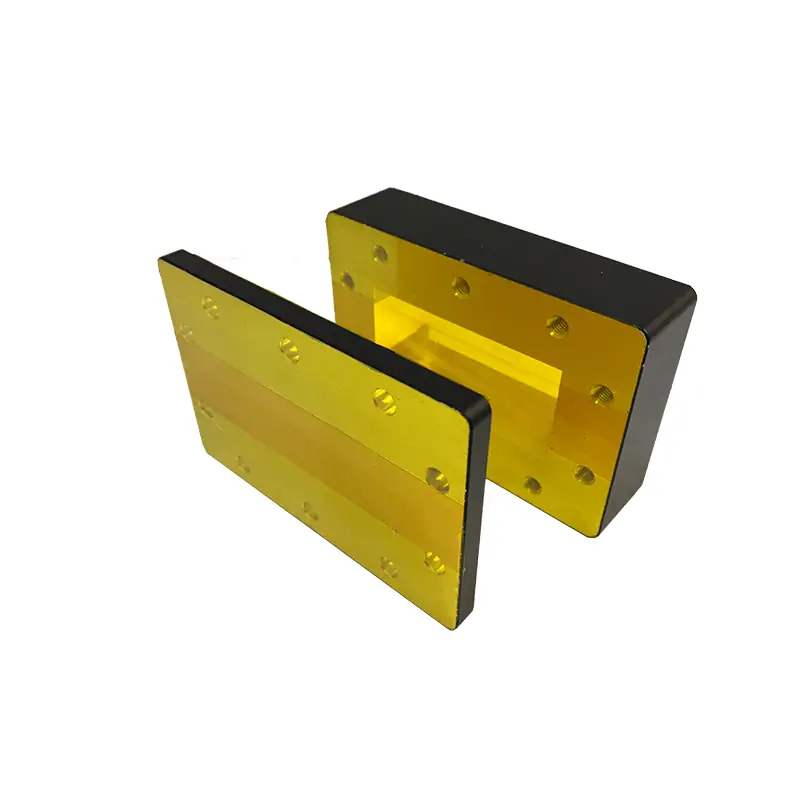

Robust Material Construction

- Material Quality: Constructed from Oxygen Free Hard Copper or Copper Alloy, ensuring durability and superior electrical performance.

Precision Engineering

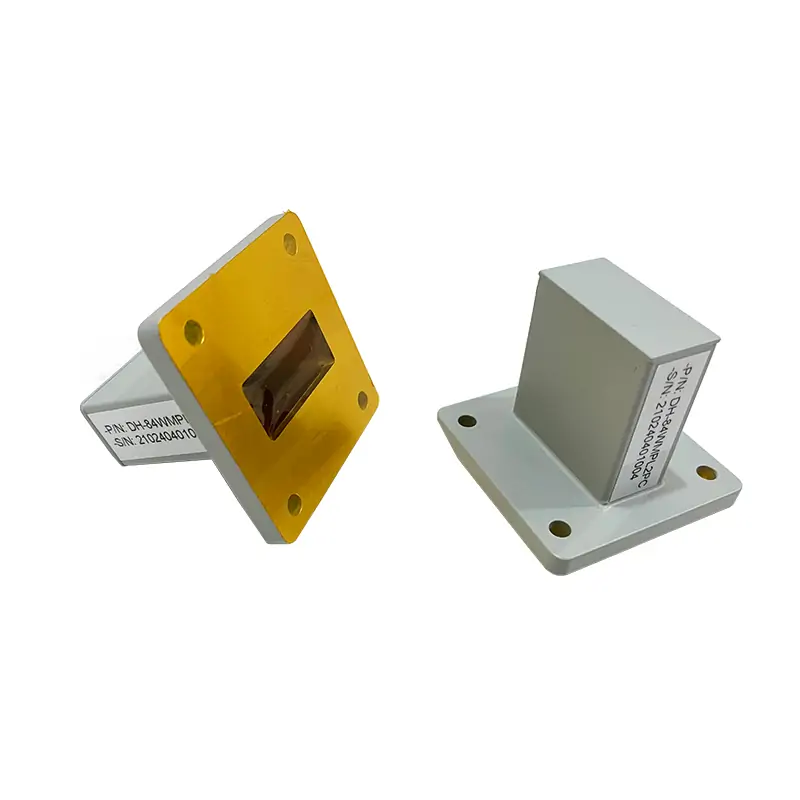

- Accurate Machining: Precision machining guarantees accurate dimensions and lasting performance, fitting standard cover or choke flanges perfectly.

Versatile Compatibility

- Waveguide Size Range: From large WR-2300 to compact WR-10, our shorts cover the entire standard waveguide size spectrum.

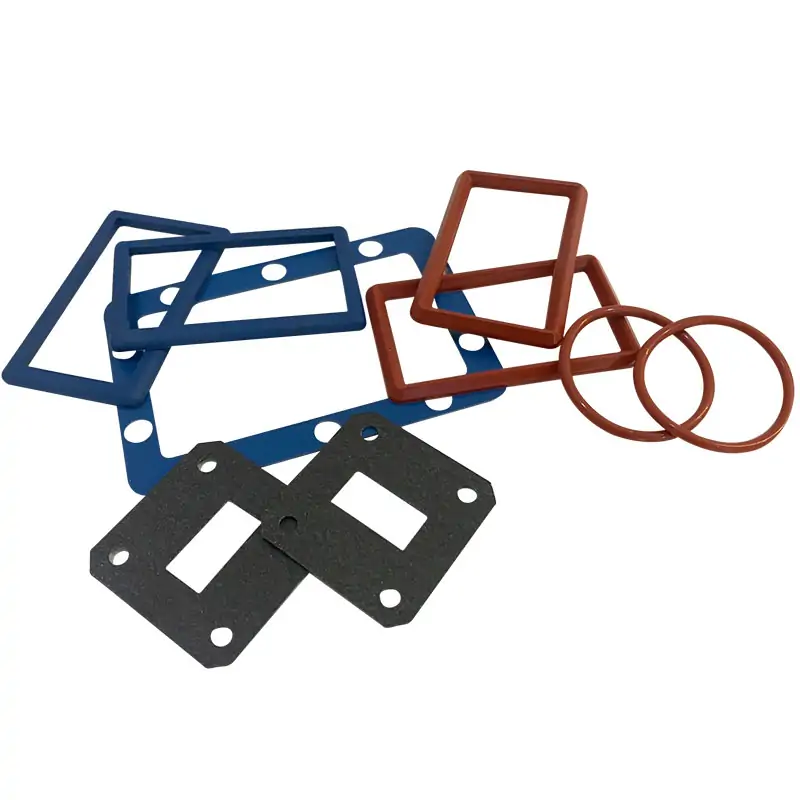

Pressure Testing Capability

- Sealing Function: Can be used with appropriate gaskets to seal waveguide ports for pressure testing, enhancing system reliability.

Applications

Waveguide shorts/shorting plates by Dolph Microwave are indispensable in a variety of settings:

- System Calibration and Testing: Essential for creating known reflection points for accurate system calibration and performance testing.

- Research and Development: Used in scientific experiments and microwave research for precise signal termination.

- Radar Systems: Integral for radar signal processing and testing, ensuring signal integrity.

- Telecommunications: Critical in the maintenance and testing of communication infrastructure.

- Satellite Communications: Used in ground station equipment for signal direction and termination.

Product Specifications Example

Here’s an example specification table for our Waveguide Shorts/Shorting Plates:

| Specification | Detail |

|---|---|

| Type | DH-100WS |

| Frequency Range | 0.32 to 112 GHz |

| VSWR | Minimum 60 |

| Thickness | 23-4 mm |

| Waveguide Size | WR-2300 to WR-10 |

| Material | Oxygen Free Hard Copper/Copper Alloy |

| Flange Compatibility | UG and CPR style |

Dolph Microwave’s waveguide shorts/shorting plates represent the pinnacle of waveguide technology, designed to meet the exacting demands of modern microwave and RF systems. Whether for standard applications or customized needs, we provide solutions that enhance system performance and reliability.

Custom Solutions and Expert Support

We understand that each project has unique requirements, which is why we offer customizable options and expert support to ensure that our products meet your specific needs. Our team is dedicated to providing the highest level of service and technical expertise.

For more detailed information or to discuss your specific requirements, please contact us. Dolph Microwave is committed to advancing your projects with our state-of-the-art waveguide solutions.

| MODEL | FREQ. RANGE (GHz) | WG SIZE | VSWR | THICKNESS (mm) | FLANGES TYPE | MATERIAL | FINISH | ROHS & REACH | DATASHEET | |

| COVER | ||||||||||

| DH-3WS… | 0.32-0.49 | WR2300 | 60 | 23 | UDR3 | Al | Chromate | Comply | STEP | |

| DH-4WS… | 0.35-0.53 | WR2100 | 60 | 23 | UDR4 | Al | Chromate | Comply | STEP | |

| DH-5WS… | 0.41-0.62 | WR1800 | 60 | 18 | UDR5 | Al | Chromate | Comply | STEP | |

| DH-6WS… | 0.49-0.75 | WR1500 | 60 | 18 | UDR6 | Al | Chromate | Comply | STEP | |

| DH-8WS… | 0.64-0.98 | WR1150 | 60 | 14 | UDR8 | Al | Chromate | Comply | STEP | |

| DH-9WS… | 0.76-1.15 | WR975 | 60 | 14 | UDR9 | Al | Chromate | Comply | STEP | |

| DH-12WS… | 0.96-1.46 | WR770 | 60 | 12 | UDR12 | Al | Chromate | Comply | STEP | |

| DH-14WS… | 1.13-1.73 | WR650 | 60 | 12 | UDR14 | Al | Chromate | Comply | STEP | |

| DH-18WS… | 1.45-2.2 | WR510 | 60 | 12 | UDR18 | Al | Chromate | Comply | STEP | |

| DH-22WS… | 1.72-2.61 | WR430 | 60 | 10 | UDR22 | Al | Chromate | Comply | STEP | |

| DH-26WS… | 2.17-3.3 | WR340 | 60 | 10 | UDR26 | Al/Cu | Chromate | Comply | STEP | |

| DH-32WS… | 2.6-3.95 | WR284 | 60 | 8 | UDR32 | Al/Cu | Chromate | Comply | STEP | |

| DH-40WS… | 3.22-4.9 | WR229 | 60 | 8 | UDR40 | Al/Cu | Chromate | Comply | STEP | |

| DH-48WS… | 3.94-5.99 | WR187 | 60 | 7 | UDR48 | Al/Cu | Chromate | Comply | STEP | |

| DH-58WS… | 4.64-7.05 | WR159 | 60 | 7 | UDR58 | Al/Cu | Chromate | Comply | STEP | |

| DH-70WS… | 5.38-8.17 | WR137 | 60 | 7 | UDR70 | Al/Cu | Chromate | Comply | STEP | |

| DH-84WS… | 6.57-9.99 | WR112 | 60 | 5 | UDR84/UBR84 | Al/Cu | Chromate | Comply | STEP | |

| DH-100WS… | 8.2-12.5 | WR90 | 60 | 5 | UDR100/UBR100 | Al/Cu | Chromate | Comply | STEP | |

| DH-120WS… | 9.84-15 | WR75 | 60 | 5 | UBR120 | Al/Cu | Chromate | Comply | STEP | |

| DH-140WS… | 11.9-18 | WR62 | 60 | 5 | UBR140 | Al/Cu | Chromate | Comply | STEP | |

| DH-180WS… | 14.5-22 | WR51 | 60 | 4 | UBR180 | Al/Cu | Chromate | Comply | STEP | |

| DH-220WS… | 17.6-26.7 | WR42 | 60 | 4 | UBR220 | Al/Cu | Chromate | Comply | STEP | |

| DH-260WS… | 21.7-33 | WR34 | 60 | 4 | UBR260 | Al/Cu | Chromate | Comply | STEP | |

| DH-320WS… | 26.3-40 | WR28 | 60 | 4 | UBR320 | Al/Cu | Chromate | Comply | STEP | |

| DH-400WS… | 32.9-50.1 | WR22 | 60 | 4 | FUGP400/UG-383U/M | Cu | Chromate | Comply | STEP | |

| DH-500WS… | 39.2-59.6 | WR19 | 60 | 4 | FUGP500/UG-383U/M | Cu | Chromate | Comply | STEP | |

| DH-620WS… | 49.8-75.8 | WR15 | 60 | 4 | FUGP620/UG-385U/M | Cu | Chromate | Comply | STEP | |

| DH-740WS… | 60.5-91.9 | WR12 | 60 | 4 | FUGP740/UG-387U/M | Cu | Chromate | Comply | STEP | |

| DH-900WS… | 73.8-112 | WR10 | 60 | 4 | FUGP900/UG-387U/M | Cu | Chromate | Comply | STEP | |

| Part Number Guide: DH-100WS5A "100"—Waveguide Size | WR90 "WS"—Waveguide Type | Straight Waveguide "5"— Thickness | 5 mm "A/C"— Material | Aluminium, Cu |

||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||