Waveguide Rotary Joint

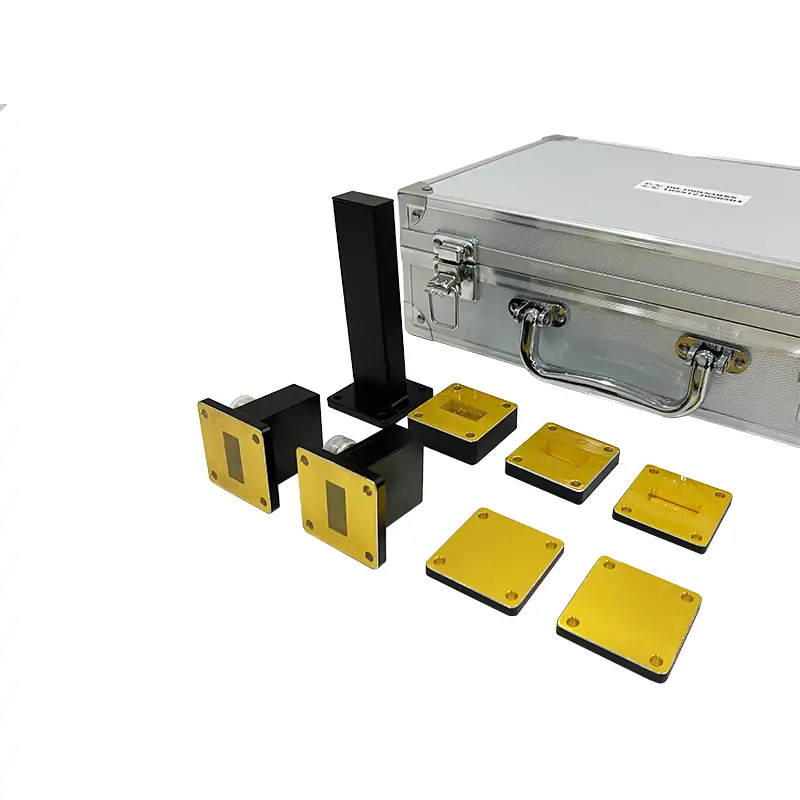

A Waveguide Rotary Joint is a mechanical device that allows for the rotation of waveguide sections while maintaining a continuous transmission path for microwave signals. It is essential in systems requiring rotation of parts, such as radar antennas and satellite communication dishes, ensuring reliable signal transmission across rotating interfaces.

Dolph Microwave offers a comprehensive range of waveguide rotary joints, designed to facilitate the seamless transmission of microwave energy between stationary and rotating systems. These rotary joints, also known as rotary couplers, are crucial components in a variety of applications where part of the system needs to rotate without interrupting the signal flow. Our products are available in multiple configurations and waveguide sizes, tailored to meet the specific needs of our customers.

Key Features

Versatile Configurations

- Physical Geometry: Available in U, L, I, or F configurations, accommodating different system designs and installation requirements.

Wide Frequency Range

- Frequency Operation: Spanning from 2.6 to 40 GHz, our rotary joints support a broad spectrum of microwave applications.

Minimal Insertion Loss

- Efficiency: Engineered for low insertion loss, typically around 0.1 dB, ensuring optimal signal integrity.

High Power Handling

- Peak Power: Capable of handling up to 600 KW, making them suitable for high-power applications.

Broad Waveguide Size Range

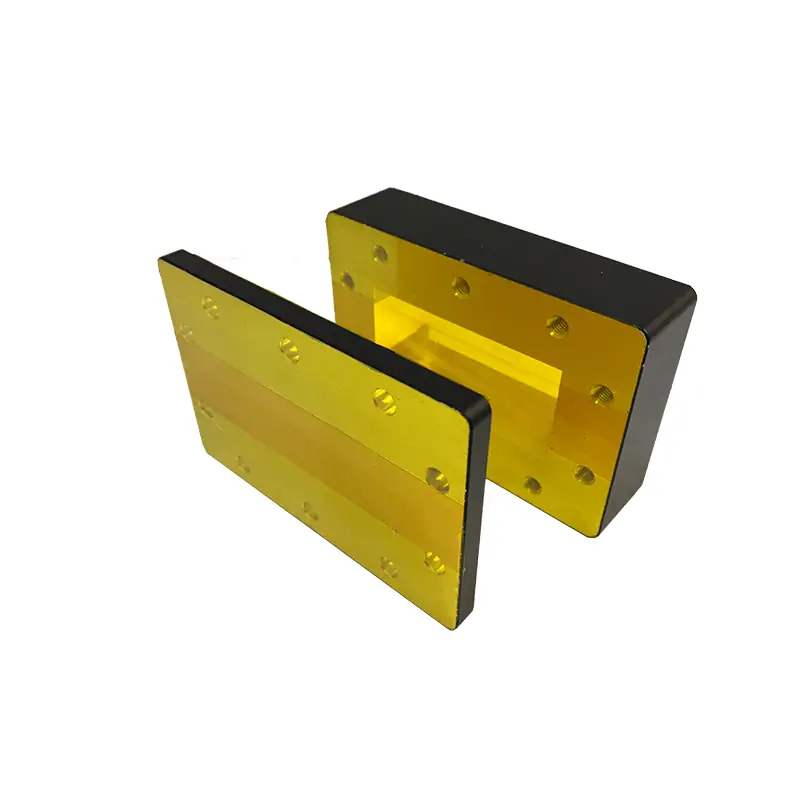

- Compatibility: From WR-284 to WR-28, offering solutions for various waveguide dimensions.

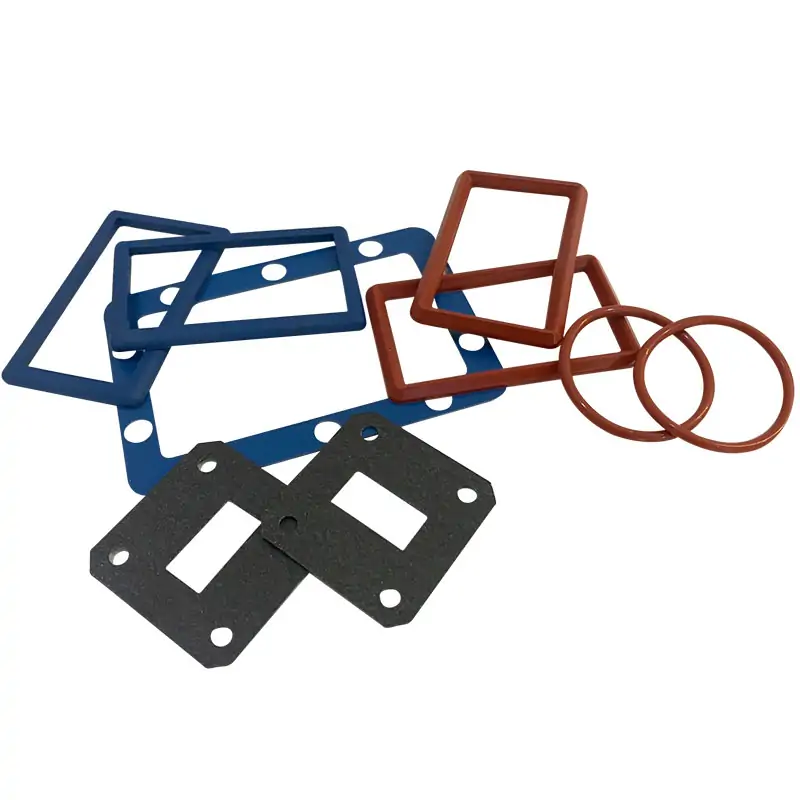

Customizable Flange Types

- Flange Options: Including cover and choke flanges, providing flexibility for system integration.

Applications

Waveguide rotary joints from Dolph Microwave are essential in multiple platforms, including:

- Radar Systems: Ground-based, shipboard, airborne, and vehicle-mounted radars for defense and civilian applications.

- Satellite Communications: Systems requiring alignment adjustments or tracking capabilities.

- Telecommunications: For antennas requiring rotational capability to optimize signal reception and transmission.

- Research and Testing Facilities: In experimental setups where components must rotate without compromising signal transmission.

- Aerospace and Aviation: In communication systems where parts of the antenna assembly need to rotate.

Product Specifications Example

Below is an example specification table for our waveguide rotary joints:

| Specification | Detail |

|---|---|

| Configuration | I-Type, L-Type, U-Type |

| Frequency Range | 2.6 to 40 GHz |

| Insertion Loss | 0.1 dB |

| Max Peak Power | 600 KW |

| Waveguide Size | WR284 – WR28 |

| Flange Type | Rectangle |

| Flange Options | Cover, Choke |

Dolph Microwave’s waveguide rotary joints are designed with precision, ensuring they meet the stringent requirements of modern microwave systems. Whether for standard or custom applications, our engineering team is dedicated to providing solutions that enhance system performance and reliability.

Custom Design and Engineering Support

Understanding the diverse needs of our clients, Dolph Microwave specializes in custom designs tailored to unique mechanical and RF specifications. Our sales engineers are available to discuss your specific requirements, offering expert advice and custom solutions.

For more detailed information or to explore custom design options, please contact us. Dolph Microwave is committed to delivering advanced waveguide solutions that drive the success of your projects.

| MODEL | FREQ RANGE (GHz) | OPERATING BW | VSWR (Max) | IL(dB) (Max) | AVG. POWER (W) | FLANGES TYPE | INGRESS PROTECTION | MATERIAL | FINISH | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-32WRJI | 2.60-3.95 | 30% | 1.2:1 | 0.25 | 600 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-32WRJL | 2.60-3.95 | 30% | 1.2 | 0.25 | 600 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-32WRJU | 2.60-3.95 | 30% | 1.2 | 0.25 | 600 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-40WRJI | 3.22-4.90 | 30% | 1.2 | 0.25 | 600 | UDR40 | PDR40 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-40WRJL | 3.22-4.90 | 30% | 1.2 | 0.25 | 600 | UDR40 | PDR40 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-40WRJU | 3.22-4.90 | 30% | 1.2 | 0.25 | 600 | UDR40 | PDR40 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-48WRJI | 3.94-5.99 | 30% | 1.2 | 0.25 | 600 | UDR48 | PDR348 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-48WRJL | 3.94-5.99 | 30% | 1.2 | 0.25 | 600 | UDR48 | PDR348 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-48WRJU | 3.94-5.99 | 30% | 1.2 | 0.25 | 600 | UDR48 | PDR348 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-58WRJI | 4.64-7.05 | 30% | 1.25 | 0.25 | 500 | UDR58 | PDR58 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-58WRJL | 4.64-7.05 | 30% | 1.25 | 0.25 | 500 | UDR58 | PDR58 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-58WRJU | 4.64-7.05 | 30% | 1.25 | 0.25 | 500 | UDR58 | PDR58 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-70WRJI | 5.38-8.17 | 30% | 1.25 | 0.25 | 500 | UDR70 | PDR70 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-70WRJL | 5.38-8.17 | 30% | 1.25 | 0.25 | 500 | UDR70 | PDR70 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-70WRJU | 5.38-8.17 | 30% | 1.25 | 0.25 | 500 | UDR70 | PDR70 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

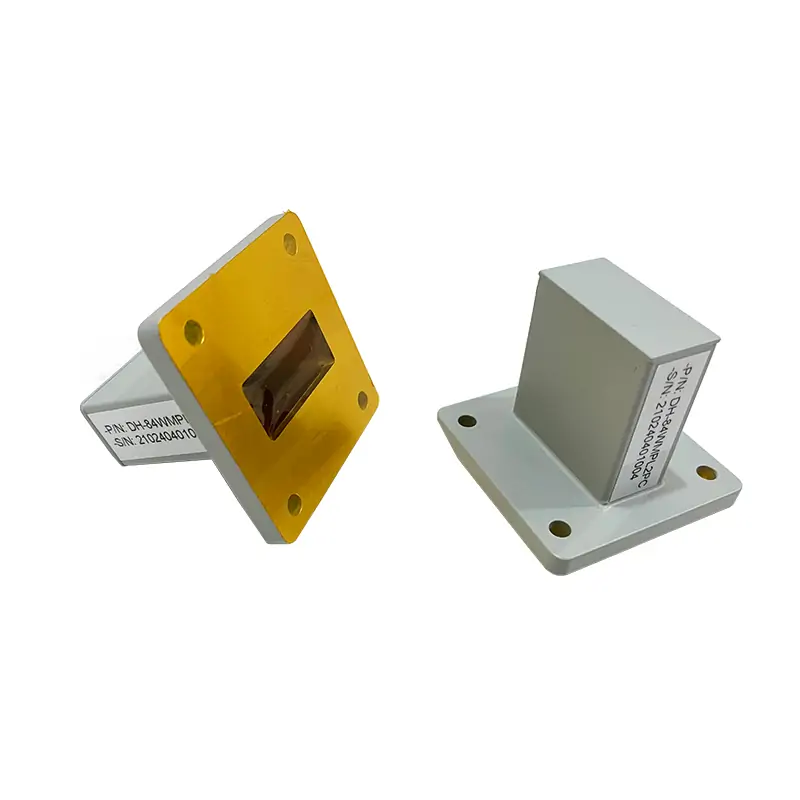

| DH-84WRJI | 6.57-9.99 | 30% | 1.2 | 0.3 | 400 | UDR84/UBR84 | PDR84/PBR84 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-84WRJL | 6.57-9.99 | 30% | 1.2 | 0.3 | 400 | UDR84/UBR84 | PDR84/PBR84 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-84WRJU | 6.57-9.99 | 30% | 1.2 | 0.3 | 400 | UDR84/UBR84 | PDR84/PBR84 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-100WRJI | 8.20-12.4 | 30% | 1.2 | 0.3 | 400 | UDR100/UBR100 | PDR100/PBR100 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-100WRJL | 8.20-12.4 | 30% | 1.2 | 0.3 | 400 | UDR100/UBR100 | PDR100/PBR100 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-100WRJU | 8.20-12.4 | 30% | 1.2 | 0.3 | 400 | UDR100/UBR100 | PDR100/PBR100 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-120WRJI | 9.84-15.0 | 30% | 1.25 | 0.3 | 200 | UBR120 | PBR120 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-120WRJL | 9.84-15.0 | 30% | 1.25 | 0.3 | 200 | UBR120 | PBR120 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-120WRJU | 9.84-15.0 | 30% | 1.25 | 0.3 | 200 | UBR120 | PBR120 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-140WRJI | 11.9-18.0 | 30% | 1.3 | 0.3 | 100 | UBR140 | PBR140 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-140WRJL | 11.9-18.0 | 30% | 1.3 | 0.3 | 100 | UBR140 | PBR140 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-140WRJU | 11.9-18.0 | 30% | 1.3 | 0.3 | 100 | UBR140 | PBR140 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-180WRJI | 14.5-22.0 | 30% | 1.3 | 0.3 | 100 | UBR180 | PBR180 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-180WRJL | 14.5-22.0 | 30% | 1.3 | 0.3 | 100 | UBR180 | PBR180 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-180WRJU | 14.5-22.0 | 30% | 1.3 | 0.3 | 100 | UBR180 | PBR180 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-220WRJI | 17.6-26.7 | 30% | 1.4 | 0.5 | 50 | UBR220 | PBR220 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-220WRJL | 17.6-26.7 | 30% | 1.4 | 0.5 | 50 | UBR220 | PBR220 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-220WRJU | 17.6-26.7 | 30% | 1.4 | 0.5 | 50 | UBR220 | PBR220 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-260WRJI | 21.7-33.0 | 30% | 1.4 | 0.5 | 30 | UBR260 | PBR260 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-260WRJL | 21.7-33.0 | 30% | 1.4 | 0.5 | 30 | UBR260 | PBR260 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-260WRJU | 21.7-33.0 | 30% | 1.4 | 0.5 | 30 | UBR260 | PBR260 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-320WRJI | 26.3-40.0 | 30% | 1.4 | 0.5 | 30 | UBR320 | PBR320 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-320WRJL | 26.3-40.0 | 30% | 1.4 | 0.5 | 30 | UBR320 | PBR320 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| DH-320WRJU | 26.3-40.0 | 30% | 1.4 | 0.5 | 30 | UBR320 | PBR320 | IP65 | Al/Cu | Chromate/Painted | DWG | STEP |

| Part Number Guide: DH-100WRJI/L/UPMA400 "100"—Waveguide Size | WR90 "WRJ"—Waveguide Type | Waveguide Rotating Joint "I/L/U"— Joint Style | I, L, U-Shape "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu "400"— Power Rating | 400 W CW. |

||||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||||