Waveguide Miter Bends

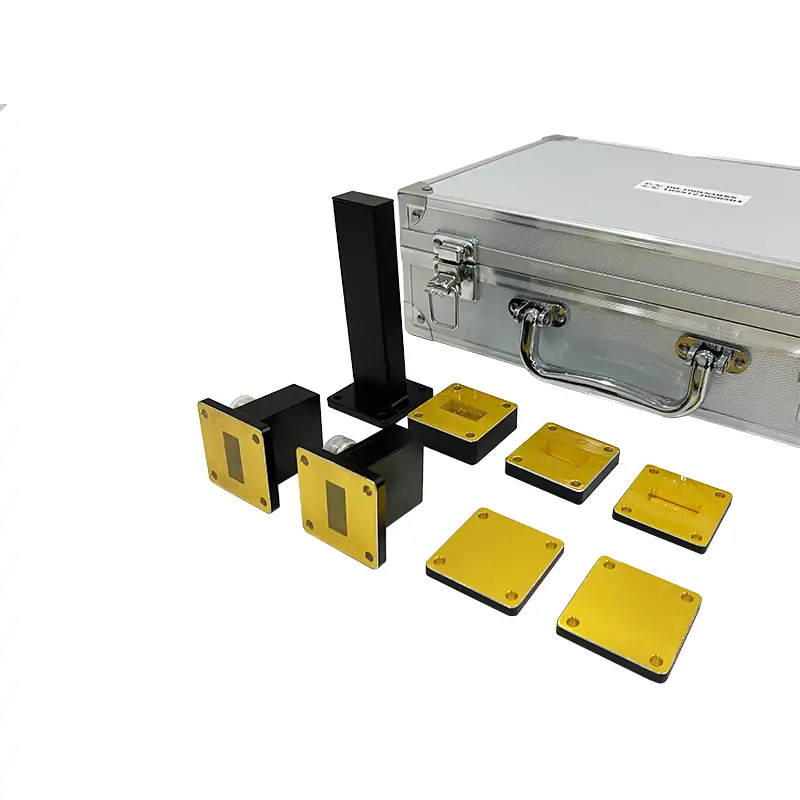

Waveguide miter bends are precision-engineered components used to change the direction of microwave signals within a waveguide system. They are designed for minimal signal loss and reflection, ensuring efficient signal transmission. These bends are critical in complex microwave systems, radar, satellite communications, and testing setups, accommodating various angles to meet specific design requirements.

Dolph Microwave specializes in the production of waveguide miter bends, offering both E-plane and H-plane configurations with angles primarily at 90°, and special orders available for 30°, 45°, and 60° bends. These components are integral in directing microwave signals within a system, ensuring minimal signal loss and reflection for efficient transmission. Our bends are designed to meet the needs of various applications, from radar systems to satellite communications, with a focus on precision and performance.

Key Features

Broad Range of Angles

- Available Angles: Standard 90° bends, with custom options for 30°, 45°, and 60°, catering to specific system requirements.

High-Quality Materials

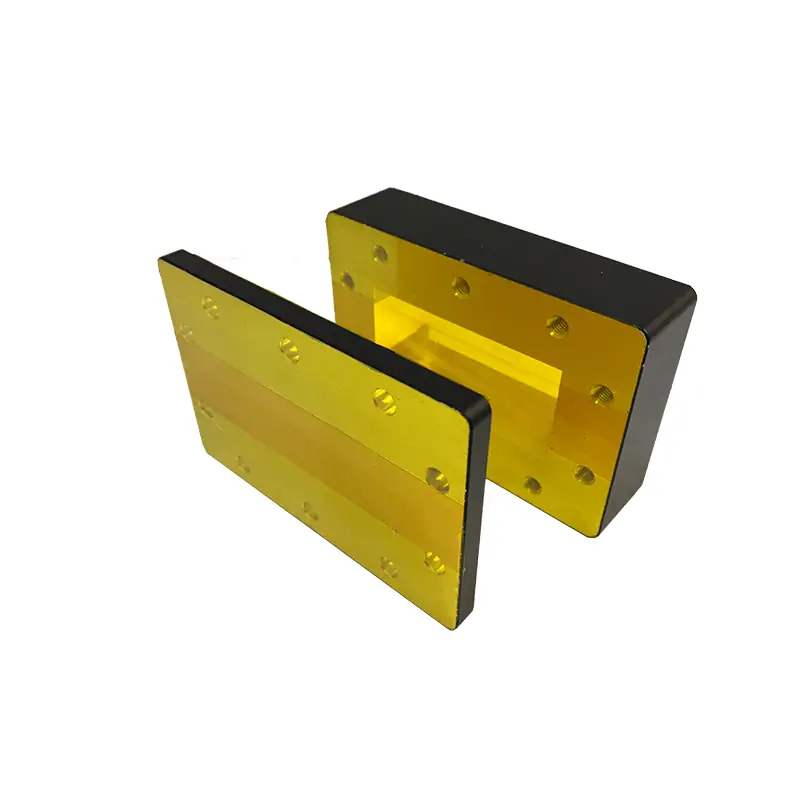

- Material Options: Manufactured in 6061 aluminum for standard applications, with options for copper and brass for enhanced electrical performance.

Exceptional Electrical Performance

- Low VSWR: Offering a Voltage Standing Wave Ratio (VSWR) typically better than 1.05, and as low as 1.03:1 over a 5% bandwidth, ensuring efficient signal transmission.

Wide Waveguide Size Range

- Waveguide Compatibility: From WR-340 to WR-2300, accommodating a large spectrum of system designs.

Customization

- Tailored Solutions: Capable of manufacturing with different flange types across a variety of sizes, plus custom e-bend/h-bend combinations per client specifications.

Durable Finishes

- Finishing: Inside surfaces feature chromate conversion for durability, while outside surfaces are protected with corrosion-resistant grey paint.

Precision Engineering

- Accurate Performance: Precision machining guarantees consistent and reliable performance across all applications.

Applications

Waveguide miter bends from Dolph Microwave are essential in a variety of settings:

- Radar Systems: Directing signals efficiently within radar equipment.

- Satellite Communications: Ensuring precise signal routing in ground station equipment.

- Telecommunications: Facilitating signal direction in microwave communication infrastructure.

- Research and Testing: Enabling accurate signal path configuration in scientific experiments and testing environments.

- Aerospace: Providing reliable signal direction in onboard communication and navigation systems.

Product Specifications Example

To illustrate, here’s an example specification table for our waveguide miter bends:

| Specification | Detail |

|---|---|

| Type | DH-100 WTEB |

| Frequency Range | 0.32 to 3.3 GHz |

| Max VSWR | 1.1:1 |

| Operating Bandwidth | 20% |

| Waveguide Sizes | WR-340 to WR-2300 |

| Material | Aluminum, Copper |

| Finishes | Chromate inside, Grey paint outside |

| Flange Type | UG, CPR, Custom |

Dolph Microwave is committed to providing high-quality waveguide solutions tailored to meet the demanding requirements of modern microwave and RF systems. Our waveguide miter bends are designed for superior performance, ensuring that your system maintains optimal signal integrity and efficiency.

Custom Solutions and Expert Support

We understand the unique challenges of microwave system design and offer customized solutions to meet your specific requirements. Our team of experts is ready to assist in selecting the right components for your project, ensuring seamless integration and optimal system performance.

For more detailed information or to discuss your specific needs, please contact us. Dolph Microwave is your partner in achieving excellence in microwave and RF system design, delivering components that exceed expectations in performance and reliability.

| MODEL | FREQ. RANGE (GHz) | OPERATING BW | WG SIZE | VSWR | IL (dB) | FLANGE TYPE | STD. SIZE (A*B) mm | MATERIAL | FINISH | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-3WTEBA*B.... | 0.32-0.49 | Full BW | WR2300 | 1.15:1 | 0.15 | UDR3 | PDR3 | 220*220 | Al/Cu | Chromate/Painted | STEP | |

| DH-3WTHBA*B.... | 0.32-0.49 | 20% | WR2300 | 1.15:1 | 0.15 | UDR3 | PDR3 | 350*650 | Al/Cu | Chromate/Painted | STEP | |

| DH-4WTEBA*B.... | 0.35-0.53 | Full BW | WR2100 | 1.15:1 | 0.15 | UDR4 | PDR4 | 200*200 | Al/Cu | Chromate/Painted | STEP | |

| DH-4WTHBA*B.... | 0.35-0.53 | 20% | WR2100 | 1.15:1 | 0.15 | UDR4 | PDR4 | 330*330 | Al/Cu | Chromate/Painted | STEP | |

| DH-5WTEBA*B.... | 0.41-0.62 | Full BW | WR1800 | 1.1:1 | 0.15 | UDR5 | PDR5 | 180*180 | Al/Cu | Chromate/Painted | STEP | |

| DH-5WTHBA*B.... | 0.41-0.62 | 20% | WR1800 | 1.1:1 | 0.15 | UDR5 | PDR5 | 300*300 | Al/Cu | Chromate/Painted | STEP | |

| DH-6WTEBA*B.... | 0.49-0.75 | Full BW | WR1500 | 1.1:1 | 0.15 | UDR6 | PDR6 | 150*150 | Al/Cu | Chromate/Painted | STEP | |

| DH-6WTHBA*B.... | 0.49-0.75 | 20% | WR1500 | 1.1:1 | 0.15 | UDR6 | PDR6 | 240*240 | Al/Cu | Chromate/Painted | STEP | |

| DH-8WTEBA*B.... | 0.64-0.98 | Full BW | WR1150 | 1.1:1 | 0.15 | UDR8 | PDR8 | 130*130 | Al/Cu | Chromate/Painted | STEP | |

| DH-8WTHBA*B.... | 0.64-0.98 | 20% | WR1150 | 1.1:1 | 0.15 | UDR8 | PDR8 | 220*220 | Al/Cu | Chromate/Painted | STEP | |

| DH-9WTEBA*B.... | 0.75-1.15 | Full BW | WR975 | 1.1:1 | 0.15 | UDR9 | PDR9 | 120*120 | Al/Cu | Chromate/Painted | STEP | |

| DH-9WTHBA*B.... | 0.75-1.15 | 20% | WR975 | 1.1:1 | 0.15 | UDR9 | PDR9 | 200*200 | Al/Cu | Chromate/Painted | STEP | |

| DH-12WTEBA*B.... | 0.96-1.46 | Full BW | WR770 | 1.1:1 | 0.15 | UDR12 | PDR12 | 110*110 | Al/Cu | Chromate/Painted | STEP | |

| DH-12WTHBA*B.... | 0.96-1.46 | 20% | WR770 | 1.1:1 | 0.15 | UDR12 | PDR12 | 160*160 | Al/Cu | Chromate/Painted | STEP | |

| DH-14WTEBA*B.... | 1.13-1.73 | Full BW | WR650 | 1.1:1 | 0.15 | UDR14 | PDR14 | 100*100 | Al/Cu | Chromate/Painted | STEP | |

| DH-14WTHBA*B.... | 1.13-1.73 | 20% | WR650 | 1.1:1 | 0.15 | UDR14 | PDR14 | 140*140 | Al/Cu | Chromate/Painted | STEP | |

| DH-18WTEBA*B.... | 1.45-2.20 | Full BW | WR510 | 1.1:1 | 0.15 | UDR18 | PDR18 | 90*90 | Al/Cu | Chromate/Painted | STEP | |

| DH-18WTHBA*B.... | 1.45-2.20 | 20% | WR510 | 1.1:1 | 0.15 | UDR18 | PDR18 | 120*120 | Al/Cu | Chromate/Painted | STEP | |

| DH-22WTEBA*B.... | 1.72-2.61 | Full BW | WR430 | 1.1:1 | 0.15 | UDR22 | PDR22 | 70*70 | Al/Cu | Chromate/Painted | STEP | |

| DH-22WTHBA*B.... | 1.72-2.61 | 20% | WR430 | 1.1:1 | 0.15 | UDR22 | PDR22 | 100*100 | Al/Cu | Chromate/Painted | STEP | |

| DH-26WTEBA*B.... | 2.17-3.30 | Full BW | WR340 | 1.1:1 | 0.2 | UDR26 | PDR26 | 70*70 | Al/Cu | Chromate/Painted | STEP | |

| DH-26WTHBA*B.... | 2.17-3.30 | 20% | WR340 | 1.1:1 | 0.2 | UDR26 | PDR26 | 100*100 | Al/Cu | Chromate/Painted | STEP | |

| DH-32WTEBA*B.... | 2.60-3.95 | Full BW | WR284 | 1.1:1 | 0.2 | UDR32 | PDR32 | 60*60 | Al/Cu | Chromate/Painted | STEP | |

| DH-32WTHBA*B.... | 2.60-3.95 | 20% | WR284 | 1.1:1 | 0.2 | UDR32 | PDR32 | 65*65 | Al/Cu | Chromate/Painted | STEP | |

| DH-40WTEBA*B.... | 3.22-4.90 | Full BW | WR229 | 1.1:1 | 0.2 | UDR40 | PDR40 | 45*45 | Al/Cu | Chromate/Painted | STEP | |

| DH-40WTHBA*B.... | 3.22-4.90 | 20% | WR229 | 1.1:1 | 0.2 | UDR40 | PDR40 | 60*60 | Al/Cu | Chromate/Painted | STEP | |

| DH-48WTEBA*B.... | 3.94-5.99 | Full BW | WR187 | 1.1:1 | 0.2 | UDR48 | PDR348 | 45*45 | Al/Cu | Chromate/Painted | STEP | |

| DH-48WTHBA*B.... | 3.94-5.99 | 20% | WR187 | 1.1:1 | 0.2 | UDR48 | PDR348 | 60*60 | Al/Cu | Chromate/Painted | STEP | |

| DH-58WTEBA*B.... | 4.64-7.05 | Full BW | WR159 | 1.1:1 | 0.2 | UDR58 | PDR58 | 40*40 | Al/Cu | Chromate/Painted | STEP | |

| DH-58WTHBA*B.... | 4.64-7.05 | 20% | WR159 | 1.1:1 | 0.2 | UDR58 | PDR58 | 50*50 | Al/Cu | Chromate/Painted | STEP | |

| DH-70WTEBA*B.... | 5.38-8.17 | Full BW | WR137 | 1.1:1 | 0.2 | UDR70 | PDR70 | 35*35 | Al/Cu | Chromate/Painted | STEP | |

| DH-70WTHBA*B.... | 5.38-8.17 | 20% | WR137 | 1.1:1 | 0.2 | UDR70 | PDR70 | 45*45 | Al/Cu | Chromate/Painted | STEP | |

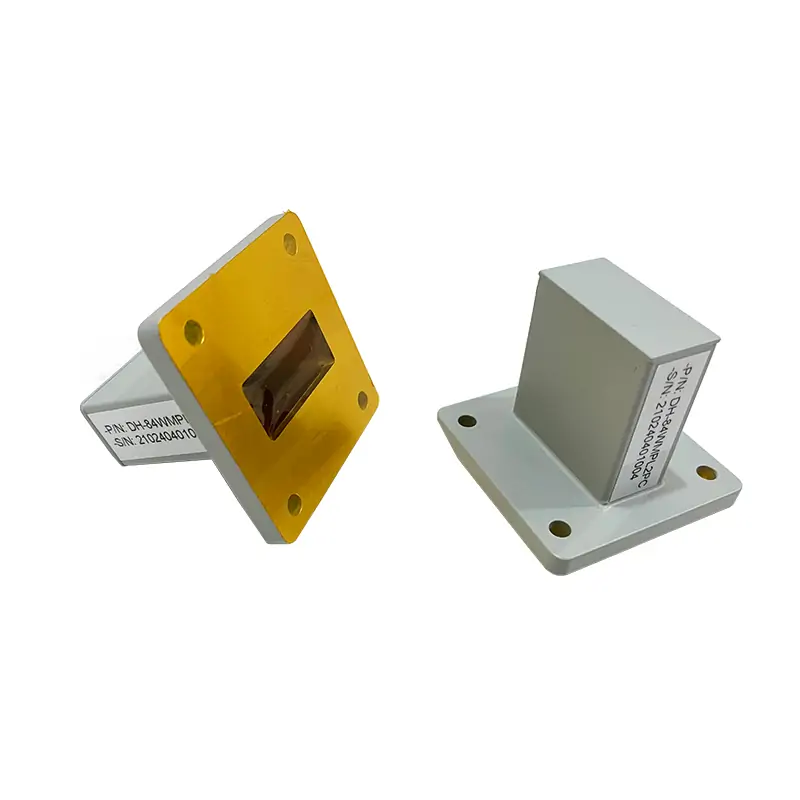

| DH-84WTEBA*B.... | 6.57-9.99 | Full BW | WR112 | 1.1:1 | 0.2 | UDR84/UBR84 | PDR84/PBR84 | 30*30 | Al/Cu | Chromate/Painted | STEP | |

| DH-84WTHBA*B.... | 6.57-9.99 | 20% | WR112 | 1.1:1 | 0.2 | UDR84/UBR84 | PDR84/PBR84 | 40*40 | Al/Cu | Chromate/Painted | STEP | |

| DH-100WTEBA*B.... | 8.20-12.40 | Full BW | WR90 | 1.1:1 | 0.2 | UDR100/UBR100 | PDR100/PBR100 | 25*25 | Al/Cu | Chromate/Painted | STEP | |

| DH-100WTHBA*B.... | 8.20-12.4 | 20% | WR90 | 1.1:1 | 0.2 | UDR100/UBR100 | PDR100/PBR100 | 30*30 | Al/Cu | Chromate/Painted | STEP | |

| DH-120WTEBA*B.... | 9.84-15.0 | Full BW | WR75 | 1.1:1 | 0.25 | UBR120 | PBR120 | 25*25 | Al/Cu | Chromate/Painted | STEP | |

| DH-120WTHBA*B.... | 9.84-15.0 | 20% | WR75 | 1.1:1 | 0.25 | UBR120 | PBR120 | 30*30 | Al/Cu | Chromate/Painted | STEP | |

| DH-140WTEBA*B.... | 11.9-18.0 | Full BW | WR62 | 1.1:1 | 0.25 | UBR140 | PBR140 | 20*20 | Al/Cu | Chromate/Painted | STEP | |

| DH-140WTHBA*B.... | 11.9-18.0 | 20% | WR62 | 1.1:1 | 0.25 | UBR140 | PBR140 | 25*25 | Al/Cu | Chromate/Painted | STEP | |

| DH-180WTEBA*B.... | 14.5-22.0 | Full BW | WR51 | 1.1:1 | 0.25 | UBR180 | PBR180 | 20*20 | Al/Cu | Chromate/Painted | STEP | |

| DH-180WTHBA*B.... | 14.5-22.0 | 20% | WR51 | 1.1:1 | 0.25 | UBR180 | PBR180 | 25*25 | Al/Cu | Chromate/Painted | STEP | |

| DH-220WTEBA*B.... | 17.6-26.7 | Full BW | WR42 | 1.1:1 | 0.25 | UBR220 | PBR220 | 15*15 | Al/Cu | Chromate/Painted | STEP | |

| DH-220WTHBA*B.... | 17.6-26.7 | 20% | WR42 | 1.1:1 | 0.25 | UBR220 | PBR220 | 20*20 | Al/Cu | Chromate/Painted | STEP | |

| DH-260WTEBA*B.... | 21.7-33.0 | Full BW | WR34 | 1.1:1 | 0.25 | UBR260 | PBR260 | 15*15 | Al/Cu | Chromate/Painted | STEP | |

| DH-260WTHBA*B.... | 21.7-33.0 | 20% | WR34 | 1.1:1 | 0.25 | UBR260 | PBR260 | 20*20 | Al/Cu | Chromate/Painted | STEP | |

| DH-320WTEBA*B.... | 26.5-40.0 | Full BW | WR28 | 1.1:1 | 0.25 | UBR320 | PBR320 | 12*12 | Al/Cu | Chromate/Painted | STEP | |

| DH-320WTHBA*B.... | 26.5-40.0 | 20% | WR28 | 1.1:1 | 0.25 | UBR320 | PBR320 | 18*18 | Al/Cu | Chromate/Painted | STEP | |

| Part Number Guide: DH-100WTEB25*25PMA "100"—Waveguide Size | WR90 "WTEB"—Waveguide Type | Miter E-Bend Waveguide "WHB"—Waveguide Type | Miter H-Bend Waveguide "25*25"— A*B Length | 25*25 mm "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu |

||||||||||||

| Note: Available Preformed bend and hybrid flexible waveguide assemblies. All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||||