Waveguide Flange Shim

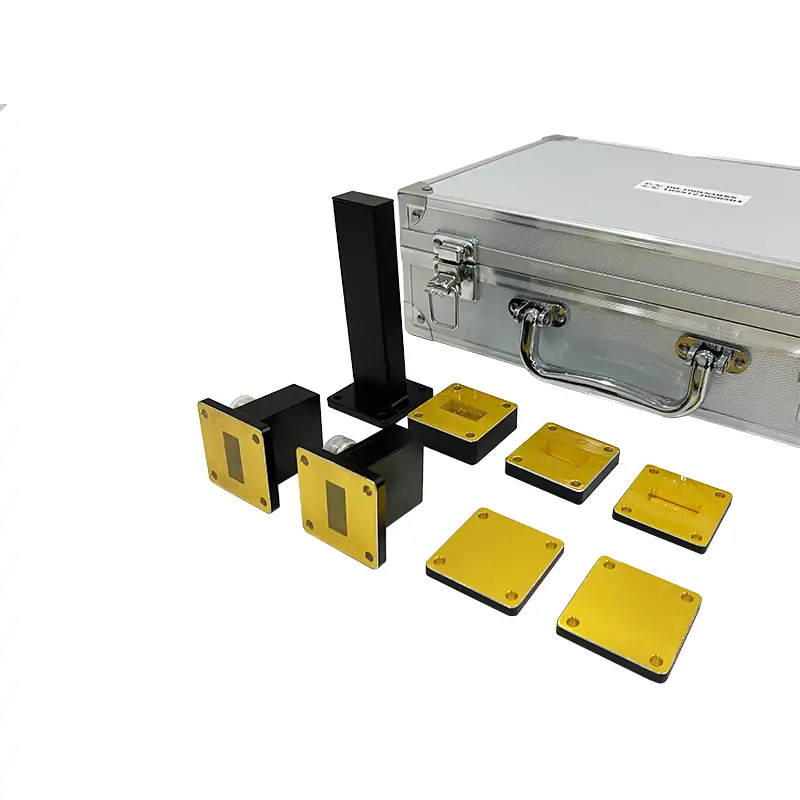

Waveguide flange shims are precision components used to ensure proper alignment and sealing between waveguide sections in microwave systems. These thin metal spacers adjust the mating surfaces for optimal connection, enhancing system performance by preventing air gaps and ensuring efficient signal transmission across various applications.

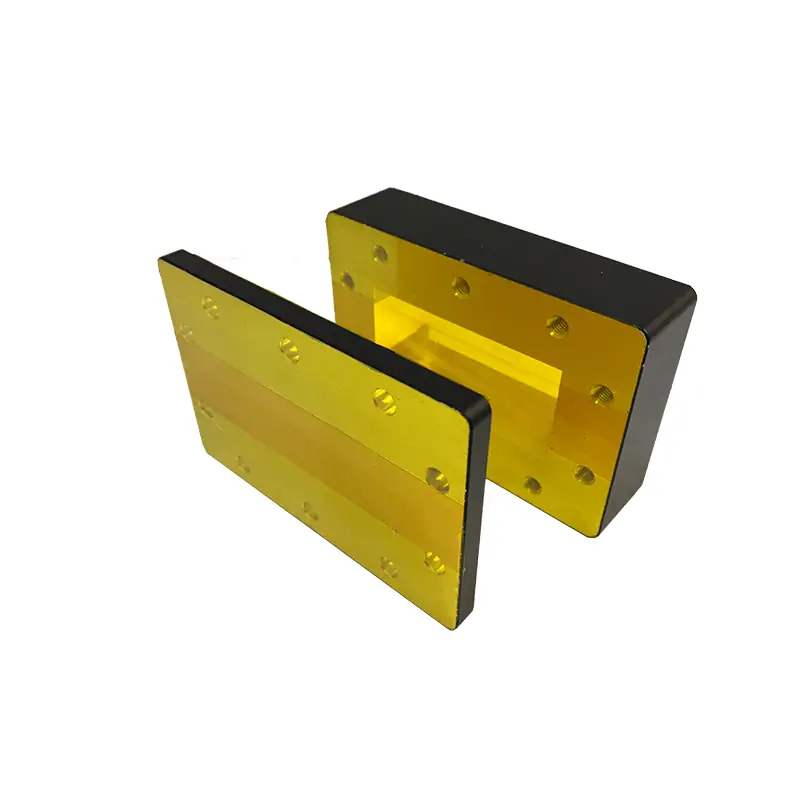

Dolph Microwave’s waveguide flange shims stand as a critical component in the seamless operation of microwave transmission systems. These shims are designed to ensure the precise alignment and efficient sealing of waveguide sections, which is paramount in maintaining signal integrity and system performance. Crafted from high-quality materials and available in a range of sizes and thicknesses, Dolph’s waveguide flange shims meet the needs of various applications, from telecommunications to radar systems.

Key Features

Precision Engineering

- Size Range: Available from WR2300 to WR10, catering to a broad spectrum of waveguide systems.

- Thickness Options: Offered in 3mm, 5mm, among others, providing flexibility in system design and alignment.

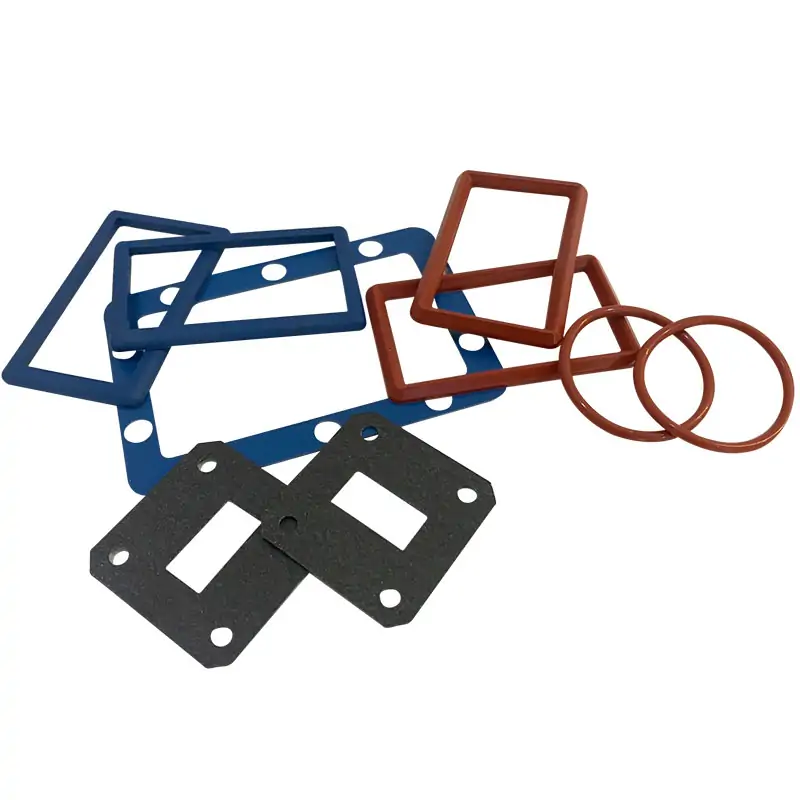

High-Quality Materials

- Construction Materials: Manufactured from aluminum (Al) and copper (Cu), ensuring durability and optimal electrical performance.

Versatility

- Types Available: Both standard and sealed options are on offer, allowing for use in environments requiring enhanced protection against elements.

Enhanced Compatibility

- Flange Types: Compatible with cover, grooved, and choke flanges, facilitating easy integration into existing systems.

Applications

Dolph Microwave’s waveguide flange shims are indispensable in a variety of settings:

- Telecommunications: Essential in satellite and ground-based communication systems for signal alignment.

- Radar Systems: Improves the reliability and accuracy of radar signal transmission in both civilian and military applications.

- Research Facilities: Utilized in scientific research for precise microwave signal management.

- Aerospace: Ensures the integrity of onboard communication and navigation systems.

- Broadcasting: Critical in the maintenance of signal quality in television and radio broadcasting infrastructure.

Example Product Specification

To illustrate the specifications Dolph Microwave offers for its waveguide flange shims, see the example table below:

| Specification | Detail |

|---|---|

| Waveguide Size | WR2300 to WR10 |

| Thickness | 3mm, 5mm, etc. |

| Type | Standard, Sealed |

| Material | Aluminum, Copper |

| Flange Type | Cover, Grooved, Choke |

Dolph Microwave not only provides a wide range of off-the-shelf options but also specializes in custom solutions tailored to specific operational requirements. Our waveguide flange shims are engineered to withstand various environmental conditions, ensuring long-lasting performance and reliability.

Customization and Support

Understanding the diverse needs of our clients, we offer both standard and customized configurations for our waveguide flange shims. Whether your application requires a specific thickness, material, or sealing capability, Dolph Microwave is equipped to provide a solution that meets your exact requirements. Our team of experts is committed to delivering high-quality components that enhance the performance and reliability of your microwave systems.

For more information or to discuss your specific needs, Dolph Microwave invites you to connect with our sales engineers. We are dedicated to providing you with the components you need to achieve unparalleled system performance.

| MODEL | FREQ. RANGE (GHz) | WG SIZE | VSWR | FLANGES TYPE | THICKNESS (mm) | MATERIAL | FINISH | DATASHEET | ||

| COVER | GROOVED | |||||||||

| DH-3WG… | 0.32-0.49 | WR2300 | 1.05:1 | UDR3 | PDR3 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-4WG… | 0.35-0.53 | WR2100 | 1.05:1 | UDR4 | PDR4 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-5WG… | 0.41-0.62 | WR1800 | 1.05:1 | UDR5 | PDR5 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-6WG… | 0.49-0.75 | WR1500 | 1.05:1 | UDR6 | PDR6 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-8WG… | 0.64-0.98 | WR1150 | 1.05:1 | UDR8 | PDR8 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-9WG… | 0.76-1.15 | WR975 | 1.05:1 | UDR9 | PDR9 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-12WG… | 0.96-1.46 | WR770 | 1.05:1 | UDR12 | PDR12 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-14WG… | 1.13-1.73 | WR650 | 1.05:1 | UDR14 | PDR14 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-18WG… | 1.45-2.2 | WR510 | 1.05:1 | UDR18 | PDR18 | 1 to 50 | Al | Chromate | FDP | STEP |

| DH-22WG… | 1.72-2.61 | WR430 | 1.05:1 | UDR22 | PDR22 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-26WG… | 2.17-3.3 | WR340 | 1.05:1 | UDR26 | PDR26 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-32WG… | 2.6-3.95 | WR284 | 1.05:1 | UDR32 | PDR32 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-40WG… | 3.22-4.9 | WR229 | 1.05:1 | UDR40 | PDR40 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-48WG… | 3.94-5.99 | WR187 | 1.05:1 | UDR48 | PDR348 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-58WG… | 4.64-7.05 | WR159 | 1.05:1 | UDR58 | PDR58 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-70WG… | 5.38-8.17 | WR137 | 1.05:1 | UDR70 | PDR70 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

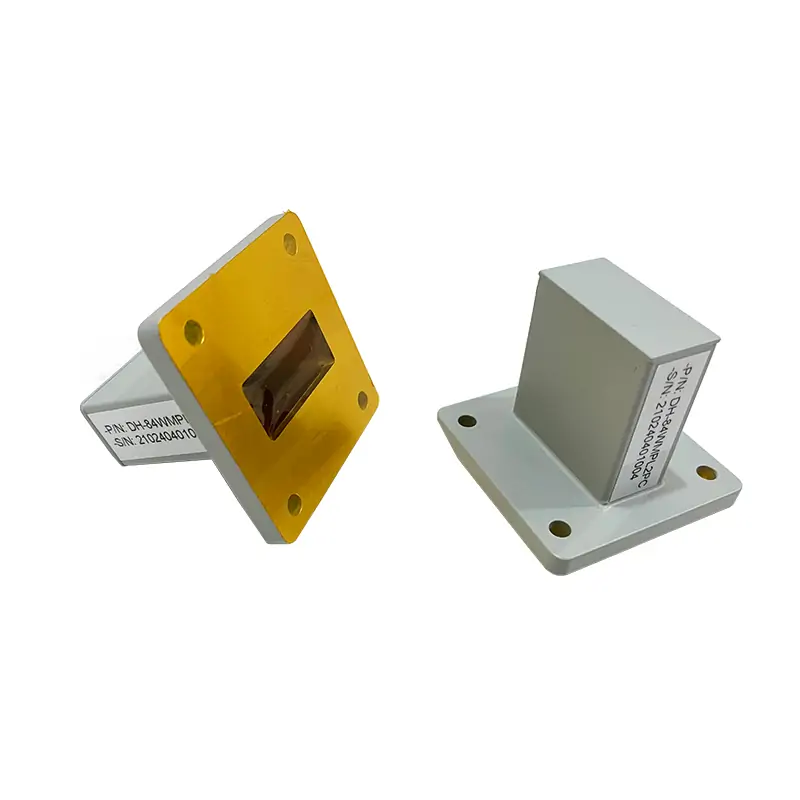

| DH-84WG… | 6.57-9.99 | WR112 | 1.05:1 | UDR84/UBR84 | PDR84/PBR84 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-100WG… | 8.2-12.5 | WR90 | 1.05:1 | UDR100/UBR100 | PDR100/PBR100 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-120WG… | 9.84-15 | WR75 | 1.05:1 | UBR120 | PBR120 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-140WG… | 11.9-18 | WR62 | 1.05:1 | UBR140 | PBR140 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-180WG… | 14.5-22 | WR51 | 1.05:1 | UBR180 | PBR180 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-220WG… | 17.6-26.7 | WR42 | 1.05:1 | UBR220 | PBR220 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-260WG… | 21.7-33 | WR34 | 1.05:1 | UBR260 | PBR260 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-320WG… | 26.3-40 | WR28 | 1.05:1 | UBR320 | PBR320 | 1 to 50 | Al/Cu | Chromate | FDP | STEP |

| DH-400WG… | 32.9-50.1 | WR22 | 1.05:1 | FUGP400/UG-383U/M | 1 to 50 | Cu | Chromate | FDP | STEP | |

| DH-500WG… | 39.2-59.6 | WR19 | 1.05:1 | FUGP500/UG-383U/M | 1 to 50 | Cu | Chromate | FDP | STEP | |

| DH-620WG… | 49.8-75.8 | WR15 | 1.05:1 | FUGP620/UG-385U/M | 1 to 50 | Cu | Chromate | FDP | STEP | |

| DH-740WG… | 60.5-91.9 | WR12 | 1.05:1 | FUGP740/UG-387U/M | 1 to 50 | Cu | Chromate | FDP | STEP | |

| DH-900WG… | 73.8-112 | WR10 | 1.05:1 | FUGP900/UG-387U/M | 1 to 50 | Cu | Chromate | FDP | STEP | |

| Part Number Guide: DH-100WG10PMA "100"—Waveguide Size | WR90 "WG"—Waveguide Type | Straight Waveguide "10"— Thickness | 10 mm, or customer to specify thickness "P"— Flange Type | Flat "M"— Flange Type | Grooved "A/C"— Material | Aluminium, Cu |

||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||