High Power Termination

High Power Termination devices are essential components in RF and microwave systems, designed to safely absorb high levels of power without reflecting it back into the system. They are critical for protecting sensitive equipment from damage, ensuring stable performance across various applications, including telecommunications, radar, and testing environments.

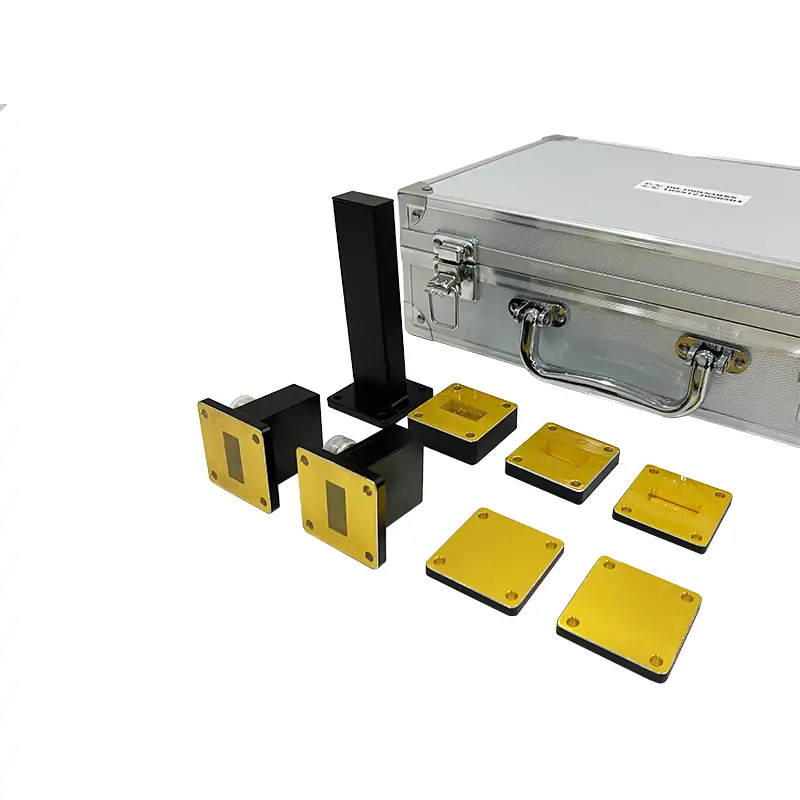

Dolph Microwave presents its range of High Power Termination devices, meticulously designed to manage and dissipate high levels of power in RF and microwave systems. Engineered for durability and efficiency, these terminations are indispensable in ensuring the protection and stable operation of sophisticated electronic equipment. Our solutions cater to a wide range of applications, from telecommunications to radar systems, offering both air and water cooling options to meet diverse operational demands.

Key Features

Wide Range of Waveguide Sizes

- Waveguide Compatibility: Spanning from WR2300 to WR10, our terminations accommodate a broad spectrum of system requirements, ensuring versatility across various applications.

High Average Power Handling

- Power Capacity: Designed to absorb power levels ranging from 100 to 6000 watts continuous wave (CW) or higher, providing reliable performance under demanding conditions.

Advanced Cooling Modes

- Cooling Options: Available in both air cooling and water cooling configurations to effectively manage heat dissipation in high-power scenarios.

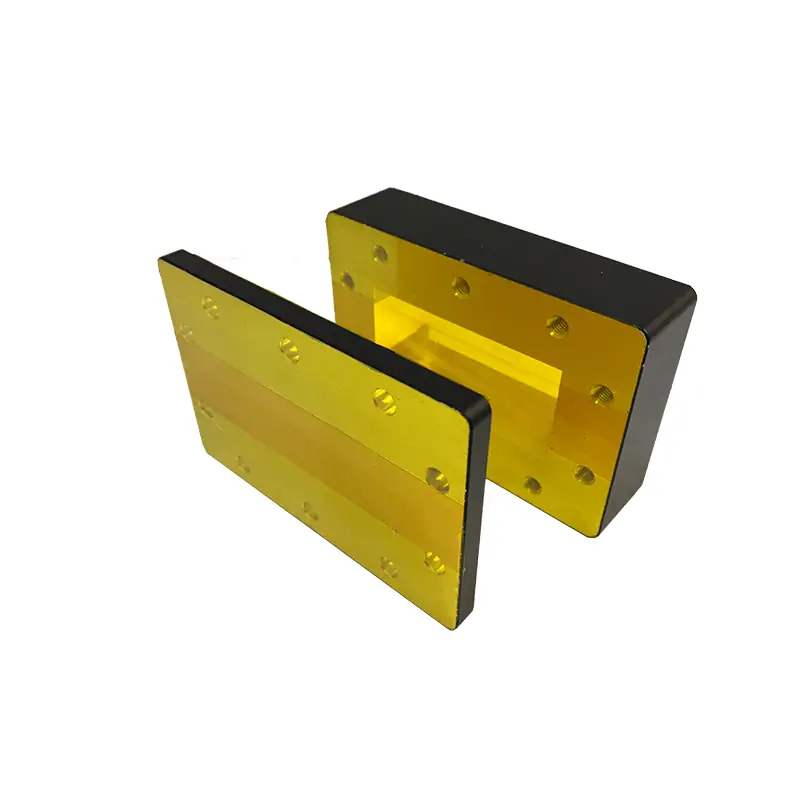

Durable Materials

- Construction Materials: Fabricated from high-quality aluminum (Al) or copper (Cu), chosen for their excellent thermal conductivity and mechanical strength.

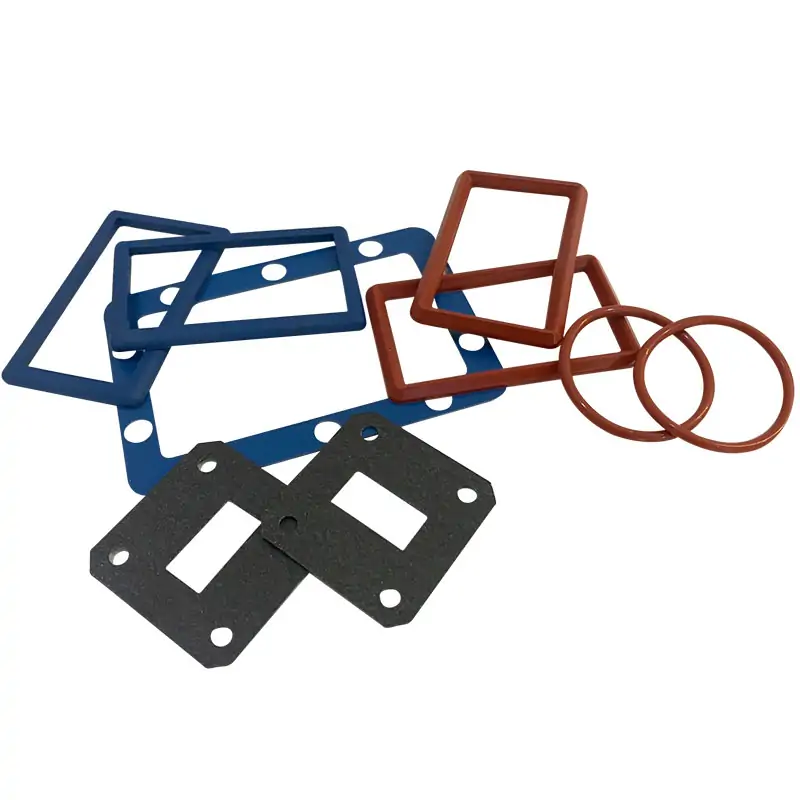

Customizable Flange Types

- Flange Varieties: Including cover, grooved, and choke flanges, allowing for seamless integration into existing systems with varying connection requirements.

Applications

Dolph Microwave’s High Power Terminations are crucial for a variety of settings:

- Telecommunications: For cellular and broadband networks, ensuring signal integrity and system protection.

- Radar Systems: In both civilian and military radar installations, providing safe termination of unused signals.

- Broadcasting: Managing high-power signals in radio and television broadcast facilities.

- Testing and Measurement: In laboratory settings, where precision and safety are paramount.

- Aerospace and Defense: For reliable operation of communication systems in harsh environments.

Product Specifications Example

Here’s an example specification table for our High Power Termination devices:

| Specification | Detail |

|---|---|

| Waveguide Size | WR2300 to WR10 |

| Average Power | 100 to 6000 watts CW or higher |

| Cooling Mode | Air Cooling, Water Cooling |

| Material | Aluminum (Al), Copper (Cu) |

| Flange Type | Cover, Grooved, Choke |

Dolph Microwave is committed to excellence, offering High Power Termination devices that stand out for their reliability, efficiency, and adaptability. Our terminations are not just components; they are comprehensive solutions designed to enhance the performance and safety of your microwave systems.

Customization and Expert Support

Recognizing the unique needs of each application, we offer customization options for our high power terminations, including specific waveguide sizes, power ratings, cooling modes, and materials. Our team of experienced engineers is available to provide expert advice and support, ensuring you select the optimal termination solution for your system’s requirements.

For further details or to discuss your specific needs, feel free to reach out to us. Dolph Microwave is your partner in achieving unparalleled system performance and reliability, safeguarding your equipment and ensuring the success of your projects.

| MODEL | FREQ. RANGE (GHz) | WG SIZE | VSWR | AVG POWER CW (W) | COOLING METHOD | FLANGES TYPE | INGRESS PROTECTION | MATERIAL | FINISH | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-14WHPL… | 1.13-1.73 | WR650 | 1.03:1 | 1000~4000 | Air Cooled | UDR14 | PDR14 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-18WHPL… | 1.45-2.2 | WR510 | 1.03:1 | 1000~3000 | Air Cooled | UDR18 | PDR18 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-22WHPL… | 1.72-2.61 | WR430 | 1.03:1 | 100~3000 | Air Cooled | UDR22 | PDR22 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-26WHPL… | 2.17-3.3 | WR340 | 1.03:1 | 100~3000 | Air Cooled | UDR26 | PDR26 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-32WHPL… | 2.6-3.95 | WR284 | 1.03:1 | 100~3000 | Air Cooled | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-40WHPL… | 3.22-4.9 | WR229 | 1.03:1 | 100~3000 | Air Cooled | UDR40 | PDR40 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-48WHPL… | 3.94-5.99 | WR187 | 1.03:1 | 100~3000 | Air Cooled | UDR48 | PDR348 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-58WHPL… | 4.64-7.05 | WR159 | 1.03:1 | 100~3000 | Air Cooled | UDR58 | PDR58 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-70WHPL… | 5.38-8.17 | WR137 | 1.03:1 | 100~3000 | Air Cooled | UDR70 | PDR70 | IP65 | Al/Cu | Chromate/Painted | STEP | |

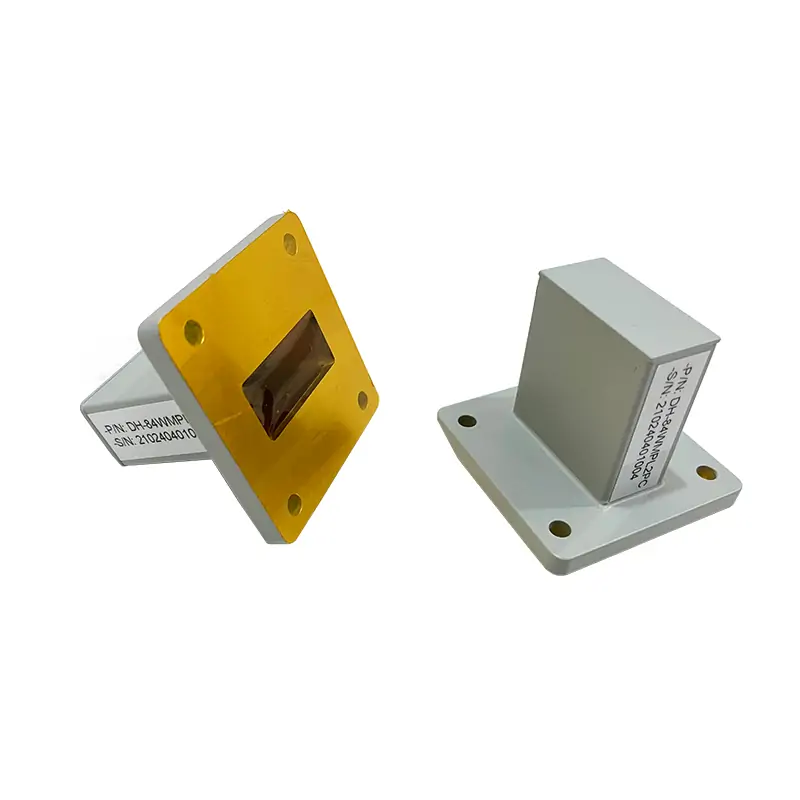

| DH-84WHPL… | 6.57-9.99 | WR112 | 1.03:1 | 100~3000 | Air Cooled | UDR84/UBR84 | PDR84/PBR84 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-100WHPL… | 8.2-12.5 | WR90 | 1.03:1 | 100~3000 | Air Cooled | UDR100/UBR100 | PDR100/PBR100 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-120WHPL… | 9.84-15 | WR75 | 1.03:1 | 100~3000 | Air Cooled | UBR120 | PBR120 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-140WHPL… | 11.9-18 | WR62 | 1.03:1 | 100~3000 | Air Cooled | UBR140 | PBR140 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-180WHPL… | 14.5-22 | WR51 | 1.03:1 | 100~2500 | Air Cooled | UBR180 | PBR180 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-220WHPL… | 17.6-26.7 | WR42 | 1.03:1 | 100~2500 | Air Cooled | UBR220 | PBR220 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-260WHPL… | 21.7-33 | WR34 | 1.03:1 | 100~2500 | Air Cooled | UBR260 | PBR260 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-320WHPL… | 26.3-40 | WR28 | 1.03:1 | 100~2500 | Air Cooled | UBR320 | PBR320 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-400WHPL… | 32.9-50.1 | WR22 | 1.15:1 | 100~1500 | Air Cooled | FUGP400/UG-383U/M | IP65 | Al/Cu | Chromate/Painted | STEP | ||

| DH-500WHPL… | 39.2-59.6 | WR19 | 1.15:1 | 100~1500 | Air Cooled | FUGP500/UG-383U/M | IP65 | Al/Cu | Chromate/Painted | STEP | ||

| DH-620WHPL… | 49.8-75.8 | WR15 | 1.15:1 | 100~1500 | Air Cooled | FUGP620/UG-385U/M | IP65 | Al/Cu | Chromate/Painted | STEP | ||

| DH-740WHPL… | 60.5-91.9 | WR12 | 1.15:1 | 10~100 | Air Cooled | FUGP740/UG-387U/M | IP65 | Al/Cu | Chromate/Painted | STEP | ||

| DH-900WHPL… | 73.8-112 | WR10 | 1.15:1 | 10~100 | Air Cooled | FUGP900/UG-387U/M | IP65 | Al/Cu | Chromate/Painted | STEP | ||

| Part Number Guide: DH-100WHPL3000PA "100"—Waveguide Size | WR90 "WHPL"—Waveguide Type | High Power Air-Cooled Loads "WWHPL"—Waveguide Type | High Power Water-Cooled Loads "3000"— Power Rating | 3000 W CW. "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu |

||||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||||