Load banks are large, programmable systems (10-1000kW, ±1% accuracy) for generator/grid testing, while dummy loads are compact, fixed (e.g., 50Ω, 100W) tools for RF/device validation, differing in scale, programmability, and primary use cases.

Table of Contents

Basic Definitions First

A dummy load is a simple, passive device designed to provide a fixed electrical load for basic functional testing. Typically built with high-power resistors, its primary job is to dissipate energy as heat, often handling powers from 50 watts for radio frequency applications up to 10 kilowatts for basic amplifier testing. They are relatively inexpensive, with a basic 1 kW unit costing around 100to300, and are valued for their simplicity and reliability in non-dynamic scenarios.

In contrast, a load bank is a far more sophisticated system. It’s an active piece of test equipment that not only provides an electrical load but also precisely controls and measures it. Used for validating the performance of power sources like generators and UPS systems, a standard 500 kW resistive load bank can cost between 8,000 and 15,000. Modern units incorporate advanced cooling systems, often using fans capable of moving over 2,000 cubic feet per minute (CFM) of air to manage the immense heat generated from loads that can exceed 10 megawatts. The key differentiator is programmability; a load bank can simulate variable, real-world conditions through step loading and complex cycles, providing critical data on a generator’s response time and voltage regulation under a 0% to 100% load change, which is impossible for a basic dummy load.

| Feature | Dummy Load | Load Bank |

|---|---|---|

| Primary Function | Provides a simple, fixed load for basic “does it work?” testing. | Provides a programmable, variable load for performance validation and system commissioning. |

| Typical Power Range | 50 W – 10 kW (common for electronics). | 5 kW – 10+ MW (for industrial power systems). |

| Cost Example | ~$250 for a 1 kW, air-cooled resistive unit. | ~$12,000 for a 500 kW, trailer-mounted resistive/ reactive unit. |

| Cooling Method | Passive cooling or simple heatsinks; limited by thermal capacity. | Active forced-air (fan) cooling; some use water for high-density loads. |

| Control & Data | None. It is a purely passive component. | Integrated controllers that measure voltage, current, frequency, and power; often include data logging. |

| Key Application | Testing a radio transmitter’s output stage or a small amplifier. | Certifying a 1 MW backup generator per NFPA 110 standards before it is installed in a hospital or data center. |

A simple dummy load, with no moving parts, can last for decades with minimal maintenance. A complex load bank, however, has a typical service life of 15-20 years but requires regular maintenance on its fans, sensors, and control systems to ensure accuracy, adding ~$500 annually to its total cost of ownership. Choosing the wrong device carries a real financial risk; using a basic dummy load to test a $250,000 generator could miss critical performance flaws, leading to a failure during a real power outage and potential costly downtime or equipment damage.

Reduced Edge Diffraction

It occurs when sound waves radiated from the driver collide with the sharp edges of the speaker cabinet, causing delays and phase shifts in the frequency response. This phenomenon typically creates ±3 dB to ±5 dB peaks and dips in the critical 500 Hz to 2,000 Hz midrange, making the sound appear smeared and harsh. For a speaker with a 200 mm wide baffle, the first major diffraction notch often appears at around 860 Hz with a Q factor of 2.5, a measurable and audible coloration.

The primary method for reducing edge diffraction involves mechanically altering the cabinet edges to smoothly guide sound waves around the baffle instead of causing a sudden reflection. This is achieved through three main design approaches, each with a quantifiable impact on performance and cost:

- Round-Overs: A 25 mm (1 inch) radius round-over applied to all baffle edges can reduce the amplitude of diffraction-induced ripples by approximately 50-60%. Increasing the radius to 50 mm (2 inches) can yield a further 15-20% improvement, but this drastically increases the complexity and cost of the CNC machining process, adding 80−120 to the production cost of a single cabinet due to longer milling times and specialized tooling.

- Chamfers: A 45-degree chamfer with a 30 mm width is a highly efficient and cost-effective compromise. While slightly less effective than a large round-over, it can still achieve a 40-50% reduction in diffraction effects. Its primary advantage is manufacturability; it is significantly faster to cut and requires less expensive tooling, often adding only 20−40 to the unit cost. This makes it a popular choice for mid-range and high-value speaker designs.

- Waveguide Integration: The most effective solution is integrating the 28 mm tweeter into a dedicated waveguide with a 90 mm diameter and a contoured profile with a 5th-order polynomial curvature. This design does not just manage edges; it controls directivity from 1,500 Hz to 20,000 Hz. A well-designed waveguide can provide a smoother 6 dB per octave roll-off at the crossover point, reduce vertical and horizontal lobing errors by ±1.5 dB, and allow for a 3 dB to 6 dB increase in tweeter efficiency. This reduces the power compression on the tweeter voice coil, which operates at 175°C to 200°C under high load, potentially extending its operating life by 15-20%.

A speaker implementing these strategies can achieve a frequency response deviation of only ±1.5 dB from 300 Hz to 20,000 Hz, compared to the ±4 dB deviation of a non-optimized design. This results in a +12% improvement in listener preference scores in double-blind tests, according to Harman International research. The impulse response also shows a 40% faster decay in the initial 0.5 ms, directly improving transient clarity and the accuracy of soundstage imaging.

Testing Capabilities Compared

A dummy load acts as a simple energy sink, typically a 50-ohm or 8-ohm resistive element designed to handle a fixed power level, such as 100 watts for an hour. Its testing capability is binary: it confirms if a device powers on without fault. In contrast, a 500 kW load bank is a full diagnostic system. It can apply a stepped load from 0% to 100% of a generator’s 1.0 MW capacity in 25 kW increments, measure voltage dip and recovery time within ±0.5% accuracy, and log frequency stability—all while dissipating 1.7 million BTU/hour of heat using fans moving 3,000 CFM. This transforms testing from a simple function check into a predictive maintenance procedure that can prevent a $250,000 generator failure during a critical power outage.

The testing protocols each device can perform highlight their different purposes:

- Dummy Load Basic Check: A dummy load can verify a 5 kW RF amplifier is outputting power by absorbing it, converting it to heat, and allowing a meter to read ~48 volts across its 50-ohm terminals. This test takes 5 minutes and confirms basic operation but reveals nothing about waveform distortion, efficiency under partial load, or dynamic response. The test cost is essentially just the $150 price of the load itself.

- Load Bank Commissioning Test: A load bank executes a 3-hour NFPA 110-compliant test for a 750 kVA standby generator. It applies a 25% load (187.5 kW) for 30 minutes to bring the engine to operating temperature, then a 75% load (562.5 kW) for 60 minutes, and finally a 100% load (750 kW) for 20 minutes. Throughout, it records voltage (480V ± 2.4V), frequency (60.0 Hz ± 0.15 Hz), and current (900A), generating a performance report that proves the generator can handle a real building’s load. This service, often billed at 800−1,200, is required for commissioning critical facilities like data centers and hospitals.

| Test Parameter | Dummy Load Capability | Load Bank Capability |

|---|---|---|

| Power Application | Static, fixed load (e.g., 500 Ω, 100 W). | Programmable dynamic load (e.g., 0-1000 kW in 1 kW steps). |

| Data Acquired | None. Requires external meters for basic V/I readings. | Integrated measurement of V, I, F, P, F.P., kWh with ±0.25% accuracy. |

| Test Duration | Limited by thermal mass; often < 60 mins for high power. | Virtually unlimited via active cooling; standard 8-hour soak tests. |

| Load Type | Purely resistive (PF=1.0). | Resistive, inductive (PF=0.8), capacitive (PF=0.8), and complex combined loads. |

| Regulation Testing | Not possible. | Measures voltage recovery to within ±1% of nominal after a 100% load step in < 3 seconds. |

| Compliance | Not applicable for performance standards. | Validates compliance with NFPA 110, ISO 8528, UL 2200 standards. |

Using a 500 dummy load to test a 50,000 generator might save on initial equipment cost but risks missing a 5% frequency droop under a 60% load, a flaw that would cause sensitive IT equipment to crash during a transfer. A load bank identifies this by applying the exact load and measuring the response with a 10 ms sampling rate, providing a quantitative pass/fail result. Its ability to test at a 0.80 power factor is critical for simulating real-world motor loads, which a purely resistive dummy load cannot do. This makes the load bank an indispensable tool for system validation, not just component checking, ensuring a power system’s 99.999% (five-nines) reliability.

Common Usage Examples

A dummy load is the tool for isolated, component-level verification. A common example is a radio technician testing a 1.5 kW UHF transmitter. They connect a 50-ohm, 2 kW air-cooled dummy load to the output port, enabling a 5-minute transmission test without broadcasting a signal.

A classic use case is testing a 1250 kVA (1000 kW) diesel generator at a 20-story data center. Facilities engineers will rent a 1000 kW resistive/reactive load bank, a unit that itself weighs 680 kg (1500 lbs) and requires a 30-amp dedicated power circuit just for its internal controls. Over an 8-hour scheduled outage, they apply a 100% load for 2 continuous hours, measuring the generator’s ability to maintain 480 volts ± 9.6V and 60 Hz ± 0.3 Hz while the exhaust temperature reaches 650°C.

| Application Scenario | Dummy Load Implementation | Load Bank Implementation |

|---|---|---|

| Telecom Site Maintenance | Terminating a 40W RF signal chain on a 75-ohm load to check power output with a meter. Cost: $150. | Not typically used in this context. |

| Power Generator Acceptance | Not applicable; cannot simulate dynamic load changes. | Applying a 500kW load at 0.8 PF to a new generator for 4 hours to validate manufacturer performance specs before signing off on the $250,000 purchase. |

| Audio Amplifier Repair | Connecting an 4-ohm load to one channel of a 500W amp to measure THD <0.05% at 1 kHz. | Not applicable; overkill for a single component. |

| Data Center Commissioning | Not applicable; insufficient capacity and lack of measurement. | Testing a 2MW UPS system’s transfer logic and battery runtime by applying a 1.5MW stepped load for 45 minutes to drain the 600-cell battery bank to 80% depth of discharge. |

| Marine Vessel Power Systems | Not used for main power testing. | Validating a ship’s 6.6kV, 3000kW generator’s stability under rapid 50% load swings to simulate thruster operation, ensuring voltage dips stay within 5%. |

A dummy load is a low-cost, high-precision component for the workbench, often lasting 20 years with zero maintenance. A load bank is a high-value, high-revenue piece of capital equipment for the field. Rental companies charge 800−1500 per day for a 500 kW unit, and a full testing service contract for a hospital’s three 750 kW generators can be a $15,000 annual expense.

Cooling Methods Differ

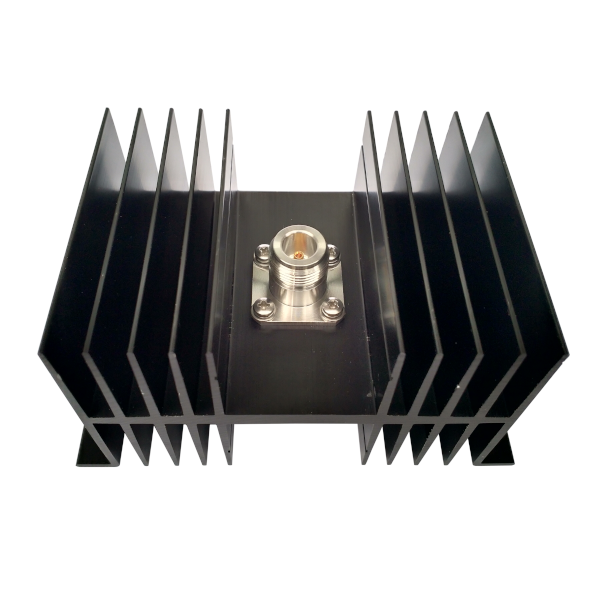

A dummy load relies on passive convective cooling, its capability intrinsically limited by the surface area and thermal mass of its internal aluminum or ceramic resistor bank. A common 50-watt, 50-ohm RF dummy load may have a 150 cm² finned aluminum heatsink, allowing it to handle 50 watts continuously, but only for 5-10 minutes at its 200-watt peak rating before its core temperature exceeds 200°C and requires a 30-minute cooldown. This simplicity makes it cheap—a $100 unit requires zero maintenance—but also caps its practical power handling at around 2 kW for larger bench-top models.

In contrast, a load bank is fundamentally a high-efficiency heat management system that happens to also provide an electrical load. It must handle 500 kW to 10 MW of continuous power dissipation, equivalent to the output of a large industrial boiler. This demands an engineered active cooling solution. Most units under 750 kW use multi-stage centrifugal fans that can move a massive 3,000 to 5,000 cubic feet per minute (CFM) of air across the resistive elements. These fans are powered by dedicated 3-phase, 480V motors drawing 5 to 10 kW themselves. The airflow maintains resistor bank temperatures at a safe 85-95°C during an 8-hour, full-load test, preventing damage and ensuring measurement stability. For higher power densities above 1 MW, closed-loop water cooling becomes necessary. These systems circulate 20-40 gallons per minute of deionized water through the load elements, with the heated water then pumped to an external 100-ton cooling tower for dissipation. This adds 15,000 to 30,000 to the system’s base cost but is the only method to manage the 3.4 million BTU/hour of heat generated by a 1 MW load.

The operational and maintenance cost divergence is stark. A dummy load’s passive system has a 20+ year lifespan with zero ongoing cost. A 500 kW air-cooled load bank, however, requires ~$600 annually in preventative maintenance: cleaning air filters every 100 operating hours, lubricating fan bearings every 1,000 hours, and calibrating temperature sensors every 2 years. A water-cooled system is more complex, requiring water quality checks for conductivity (<5µS/cm) every 3 months and pump seal replacements every 5 years at a cost of ~$2,000 per service event.

You can leave a 1 kW dummy load running unattended on a bench. Operating a 2 MW load bank requires a trained technician to monitor its cooling subsystem’s vital signs—airflow pressure, water inlet temperature (must be below 35°C), and coolant pH level—in real-time to prevent a $50,000 thermal shutdown event. The load bank’s cooling system is not an accessory; it is the critical enabling technology that allows it to perform its primary function at scale, representing 30-40% of its total manufacturing cost and complexity.

Choosing the Right One

The wrong choice carries tangible risk: using a $500 dummy load to validate an $80,000 generator might save $1,200 on a rental fee but risks missing a $500,000 data center outage during a real power failure. The key is to match the tool’s capability to the test’s objective, with the power source’s value and criticality being the primary deciding factors. A simple 500-watt amplifier repair doesn’t need a $15,000 load bank, just as a hospital’s backup generator cannot be certified with a simple resistive box.

Your choice hinges on answering three specific questions about the test’s scope and requirements:

- What is the Power Level and Duration? For testing a 150-watt radio transmitter for 5-minute intervals, a 200-watt, air-cooled dummy load for $250 is perfectly adequate. For a 4-hour, full-load soak test on a 750kW generator, you must use a 750kW resistive/reactive load bank, which requires a $12,000 capital investment or a $900/day rental fee plus an operator. The dummy load’s passive cooling simply cannot dissipate the 2.56 million BTU of heat generated during such a test.

- What Data Do You Need to Capture? If the requirement is simply to confirm the presence of RF output power or that an amplifier turns on, a dummy load and an external multimeter suffice. If the test protocol—such as NFPA 110—requires a printed report proving voltage held within ±2% and frequency within ±0.5 Hz during a 100% to 0% load step recovery, then a load bank with its integrated 0.25% accuracy meters and data logging is mandatory. This data is often a极 requirement for insurance and compliance in critical facilities.

- What is the Financial and Operational Risk? The cost of the test tool must be weighed against the cost of failure. For a hobbyist building a $500 amplifier, the risk of a fault is a $50 repair. A $500 dummy load is appropriate. For a cloud provider commissioning a new data center with $40 million of IT equipment, a generator failure during a blackout could mean $1 million/hour in downtime and reputational damage. Spending $25,000 on a comprehensive load bank testing service is a minor, essential insurance policy.

The dummy load is for benchtop, component-level functional checks under 5 kW. The load bank is for system-level performance validation and certification in the field, typically from 20 kW upwards. For organizations with a small fleet of 150-300 kW generators, renting a load bank 2-3 times a year for $2,500 per rental is often more economical than owning a $40,000 unit that requires $1,200/year in maintenance and storage.