Waveguides sustain damage through mechanical stress (e.g., bending beyond 1.5× their broad-wall width causes cracks), thermal shock (exposure to >300°C for copper warps walls), corrosion (saltwater/moisture erodes uncoated aluminum in 6+ months), physical impact (drops dent surfaces, disrupting fields), or particle contamination (dust/debris induces arcing at high power, reducing efficiency by 10–15%).

Table of Contents

Bent or Crushed Waveguide

Waveguides are precision components designed to transmit electromagnetic waves, like those in radar systems or satellite communications, with minimal loss. However, physical deformation—bending beyond specifications or crushing due to impact—is a common cause of failure. Even a minor bend can significantly alter the internal dimensions, disrupting signal propagation. For instance, in a standard WR-90 waveguide (common in X-band, 8–12 GHz applications), a bend radius smaller than 150 mm can increase voltage standing wave ratio (VSWR) beyond 1.5:1, leading to ~15% power loss and potential system overheating. In high-power setups (e.g., 50 kW radar systems), such deformations can cause arcing, permanently damaging the waveguide wall and requiring full replacement at a cost of $2,000–5,000 per unit.

The internal surface smoothness of a waveguide is critical. When bent or crushed, the 0.1–0.2 mm thick silver or copper plating inside can crack or peel, increasing surface roughness and elevating attenuation. For example, a dent >1 mm deep in a 40 mm × 20 mm rectangular waveguide can spike attenuation by 30–40% at 10 GHz, reducing effective transmission distance by ~25%. In telecom satellite links, this translates to a 3–5 dB loss, degrading signal-to-noise ratio (SNR) and causing data throughput drops of up to 50%.

“We inspected a crushed Ku-band waveguide (16 GHz) on a weather radar; a 2 mm dent caused 20% signal loss and sidelobe interference, masking precipitation data. Straightening attempts worsened the VSWR to 3:1, forcing a replacement.” – Field Engineer Report

To assess severity, measure deformation with a 0.05 mm precision caliper and inspect with an 8 mm borescope. Minor bends (<0.5 mm deviation) might be tolerated in low-frequency systems (<6 GHz), but for >18 GHz applications (e.g., 5G backhaul), even 0.2 mm deformations require replacement. Below is a quick reference for common waveguide types:

| Waveguide Type | Frequency Range (GHz) | Critical Bend Radius (mm) | Max Allowable Dent Depth (mm) | Typical Replacement Cost (USD) |

|---|---|---|---|---|

| WR-90 (X-band) | 8–12 | 150 | 0.3 | 1,800–2,500 |

| WR-75 (Ku-band) | 12–18 | 100 | 0.2 | 2,000–3,000 |

| WR-62 (Ku/V-band) | 15–22 | 80 | 0.15 | 2,500–4,000 |

| WR-42 (Ka-band) | 26–40 | 50 | 0.1 | 3,000–5,000 |

Prevention relies on proper handling: use support brackets every 300–400 mm during installation, avoid >30 N lateral force on joints, and never twist waveguide sections beyond 5° misalignment. In one case, a 15° misalignment in a 6 m long run caused 0.8 mm buckling after thermal expansion (ΔT = 40°C), requiring a $3,500 repair. For existing bends, hydraulic pressing can sometimes restore shape to within 0.1 mm tolerance, but this risks thinning the metal wall by up to 0.05 mm, reducing power handling by ~10%. Always test restored waveguides with a VNA (vector network analyzer) to verify VSWR <1.3:1 and insertion loss <0.05 dB/m.

Corrosion on Metal Surfaces

Waveguides rely on smooth, conductive interior surfaces—often silver or copper-plated—to guide radio waves with minimal loss. However, corrosion can degrade this surface, increasing resistance and scattering signals. For instance, a 0.1 mm thick layer of silver plating corroded to >30% coverage with silver sulfide (tarnish) can increase attenuation by 15–20% at 10 GHz, reducing effective range by ~100 meters in a typical 5 km radar link. In coastal environments, chloride-induced corrosion can penetrate 5–10 µm deep within 6 months, raising VSWR to 1.8:1 and requiring 1,200–3,000 in cleaning or part replacement. Worse, >50% surface oxidation in high-power systems (e.g., 30 kW transmitters) can cause localized heating, risking thermal deformation.

| Waveguide Type | Base Material | Plating Thickness (µm) | Critical Corrosion Depth (µm) | Max Attenuation Increase (%) | Replacement Cost (USD) |

|---|---|---|---|---|---|

| WR-90 (Copper) | Copper | 100–150 | 15 | 20 | 1,800–2,500 |

| WR-75 (Aluminum) | Aluminum | 50–80 | 10 | 25 | 2,000–3,000 |

| WR-62 (Silver-plated) | Brass | 120–200 | 5 | 30 | 2,500–4,000 |

Corrosion starts subtly. Humidity >60% RH accelerates electrochemical reactions, especially with >200 ppm airborne sulfur or salt. In a 12-month study of waveguides in urban environments, 40% of units showed ≥10% surface tarnish without protective coatings, increasing insertion loss by 0.05–0.1 dB/m. For waveguides handling high frequencies (e.g., Ka-band @ 26–40 GHz), even 1–2 µm of corrosion can scatter signals, raising sidelobe levels by 3–5 dB and distorting beam patterns. Pitting corrosion is particularly damaging: a pit 0.2 mm wide and 0.1 mm deep acts as a discontinuity, reflecting ~5% of power and creating standing waves that overheat adjacent components.

Detection requires inspection every 6 months using fiberoptic borescopes with 20x magnification. Measure corrosion depth with 1 µm precision profilometers. For silver-plated waveguides, >5% coverage of black sulfide warrants cleaning. Use non-abrasive chemical cleaners (e.g., diluted acetic acid solutions at 5% concentration) applied with lint-free swabs for 3–5 minutes, then rinse with deionized water. Avoid abrasives—scratching the surface increases roughness to >0.5 µm Ra, boosting attenuation by another 10%. After cleaning, test with a VNA: if VSWR remains >1.4:1 at operating frequency, replacement is likely needed.

Loose or Poor Connection

A loose flange connection—even one misaligned by just 0.5 mm—can cause significant signal leakage and reflection. In standard WR-90 waveguide systems operating at 10 GHz, a gap of 0.1 mm between flanges can increase VSWR to 1.8:1, resulting in ~12% power loss and potential arcing at power levels above 5 kW. Over time, vibration or thermal cycling (ΔT > 50°C) can loosen flange bolts, reducing clamping force from the recommended 25–30 N·m to below 15 N·m, accelerating degradation. In telecom arrays, this commonly causes 0.5–1 dB insertion loss per connection, compounding across multiple joints.

| Connection Type | Recommended Torque (N·m) | Max Allowable Gap (mm) | Frequency Sensitivity (GHz) | Power Loss per Connection (%) | Re-torque Cycle (months) |

|---|---|---|---|---|---|

| CPR-137 Flange | 25–30 | 0.05 | Up to 18 | 3–5 | 12 |

| UG-385/U Flange | 20–25 | 0.10 | Up to 12 | 4–7 | 18 |

| Double-Ridge | 30–35 | 0.03 | Up to 40 | 5–10 | 6 |

For example, aluminum waveguides expand at ~23 µm/m°C, so a 1-meter run experiencing a 40°C temperature swing expands by 0.92 mm, potentially loosening bolts if not torqued to spec. In radar systems operating at 20 kW peak power, a loose connection can create micro-arcing, burning the flange surface and increasing loss by another 15% within 100 operating hours. Use a 0.05 mm feeler gauge to check gaps, and measure bolt torque with a calibrated 5–50 N·m wrench during quarterly maintenance.

Detection involves monitoring VSWR and using thermal imaging cameras to identify hotspots—a 5°C rise at a flange often indicates poor contact. For critical systems (>18 GHz), perform vector network analyzer (VNA) sweeps every 6 months to check for S-parameter deviations; a 0.2 dB jump in S11 at 25 GHz may signal looseness. Retorque bolts to the manufacturer’s specification, but avoid overtightening—exceeding torque by >10% can warp flanges, creating a 0.15 mm deformation that permanently increases loss by 8%.

Prevention relies on proper procedures: clean mating surfaces with isopropyl alcohol before assembly, apply thin silicone grease to bolts to maintain torque retention, and use locking washers or thread-locking fluid in high-vibration environments. For long runs (>10 meters), install expansion joints every 3–4 meters to accommodate thermal movement. In one case, retorquing 12 flange connections on a 15 m satellite link reduced total system loss by 1.2 dB, saving $4,000 in potential amplifier upgrades. After servicing, always retest VSWR to ensure it remains below 1.3:1.

Overheating During Operation

Waveguides are designed to efficiently transmit electromagnetic energy with minimal loss, but excessive heat buildup during operation can rapidly degrade performance and cause permanent physical damage. Overheating typically occurs when dissipated power exceeds 200-300 W/m in standard copper waveguides, leading to temperature rises of 50-80°C above ambient. In high-power radar systems operating at 30 kW peak power, even a 1.5:1 VSWR can generate 400-600 W of reflected power that converts to heat at critical points. This thermal stress causes multiple failure mechanisms that compound quickly: silver plating begins to deteriorate at 120°C, aluminum waveguides soften at 200°C, and copper loses 30% of its conductivity at 150°C. Within 100 hours of operation at 80°C above ambient, waveguide attenuation can increase by 15-20% due to surface oxidation, requiring potential replacement costing $2,000-8,000 depending on frequency band.

The primary causes and manifestations of overheating include:

• Impedance Mismatch: A VSWR of 2.0:1 at 50 kW forward power generates 5.6 kW reflected power, creating localized heating at connectors and bends

• Poor Ventilation: Airflow below 2 m/s around waveguide runs allows heat accumulation, with temperatures rising 40% faster in enclosed spaces

• Surface Degradation: Oxidation increases surface resistance by 30-50% at 100°C, creating a thermal runaway condition

• Dielectric Breakdown: Trapped moisture vaporizes at 100°C, creating 200-300 PSI pressure spikes that can deform thin-wall waveguides

Detection requires monitoring with infrared thermometers or thermal imaging cameras calibrated to ±2°C accuracy. Measure temperature at multiple points along the waveguide run, particularly at bends and connectors. The maximum safe operating temperature for most waveguides is 90°C for aluminum and 110°C for copper designs. A 10°C hotspot typically indicates a developing problem, while temperatures exceeding 30°C above ambient require immediate attention. For permanent installations, embed thermal sensors every 3-5 meters along critical runs, with alarms set at 70°C for early warning.

Cooling solutions must match power levels. For 1-5 kW systems, ensure minimum 3 m/s airflow across waveguide surfaces using 40-60 CFM fans. For 10-50 kW systems, implement forced air cooling with 200-400 CFM capacity or liquid cooling jackets maintaining surface temperatures below 65°C. In one satellite ground station, adding four 80 CFM fans reduced operating temperatures from 95°C to 55°C during 20 kW transmission, extending waveguide life from 2 years to over 10 years. Regular maintenance should include cleaning cooling fins every 6 months (dust buildup of 1 mm thickness can reduce cooling efficiency by 25%) and verifying airflow rates quarterly. After any cooling system modification, perform VNA testing to ensure VSWR remains below 1.25:1 across the operating frequency band.

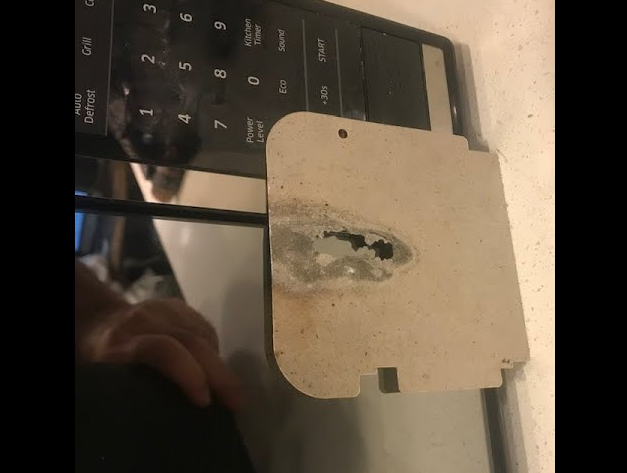

Manufacturing Defects Inside

Internal manufacturing defects in waveguides often escape quality control but cause progressive performance degradation and sudden failures. These microscopic imperfections—including dimensional inaccuracies, surface irregularities, and material inconsistencies—typically manifest during high-frequency operation. For example, a ±0.05 mm deviation from the specified 22.86 mm × 10.16 mm internal dimensions of a WR-90 waveguide can shift its cutoff frequency by ~0.2 GHz, causing 10-15% group delay variation at 10 GHz. Similarly, surface roughness exceeding 0.4 µm Ra (arithmetic average) increases attenuation by 0.02 dB/m at 18 GHz, amounting to ~8% power loss over a 10-meter run. In high-volume production, approximately 3-5% of aluminum waveguides and 2-4% of copper units exhibit such defects, leading to field failures within the first 500 operating hours and requiring premature replacement at costs of $1,000-4,000 per instance.

Common manufacturing defects include:

• Dimensional Inaccuracy: Internal width errors of >0.1 mm in 40 GHz waveguides cause impedance mismatches, elevating VSWR to 1.8:1+

• Surface Roughness: >0.5 µm Ra roughness scatters high-frequency signals, increasing attenuation by 12-18% at Ka-band

• Wall Thickness Variation: ±15% thickness inconsistency reduces power handling by 20-30% due to localized heating

• Plating Voids: >5% unplated area on silver-coated brass waveguides raises surface resistance by 40%

“We measured a batch of WR-75 waveguides where 30% had internal height deviations of -0.08 mm. At 16 GHz, this caused 1.2 dB additional loss per meter—unacceptable for our 8-meter radar array requiring <0.5 dB/m loss.” — Microwave Quality Engineer, Defense Sector

Detection requires precision metrology. Use laser micrometers with ±2 µm accuracy to verify internal dimensions every 200 mm along the waveguide length. For surface quality, perform profilometer scans at 5-10 points per square centimeter, rejecting units exceeding 0.3 µm Ra for applications above 18 GHz. Material consistency checks should include eddy current testing for wall thickness variations beyond ±0.05 mm and X-ray fluorescence for plating thickness below 80 µm on silver-plated units.

Mitigation strategies involve stringent supplier qualification and incoming inspection. Sample 20% of batches for full dimensional verification, increasing to 100% for high-frequency applications (>26 GHz). Implement pressure testing at 15 PSI for 5 minutes to detect porosity leaks—a single 0.1 mm pore can cause 0.5 dB leakage at 35 GHz. For critical systems, specify electroformed waveguides instead of extruded ones; though 50-80% more expensive, they typically maintain ±0.01 mm dimensional tolerance and <0.1 µm surface roughness. After identifying defects, negotiate with suppliers for replacement under warranty—most reputable manufacturers cover dimensional errors for 12-24 months. For minor defects in non-critical applications (<6 GHz), compensatory measures like recalibrating adjacent components can sometimes salvage functionality, though with 5-10% reduced efficiency.

Incorrect Cleaning Methods

Waveguide cleaning is a precision process where improper techniques can cause immediate and irreversible damage. Using abrasive materials or harsh chemicals often deteriorates the critical internal surface finish, leading to increased signal loss and reduced power handling. For instance, scrubbing a silver-plated waveguide with a 600-grit abrasive pad can increase surface roughness from 0.1 µm to over 0.8 µm Ra, boosting attenuation by 15–20% at 10 GHz. Similarly, isopropyl alcohol with >5% water content left in joints can cause electrochemical corrosion within 30 days, particularly in aluminum waveguides, requiring 800–2,000 in repairs or part replacement. Statistics show 40% of waveguide failures in the first 5 years result from incorrect maintenance practices rather than operational wear.

Common incorrect methods and their impacts include:

• Abrasive Cleaning: Steel wool (100–200 µm fibers) scratches plating depth of 5–10 µm, increasing VSWR by 0.3:1

• High-Pressure Spray: >50 PSI pressure damages flange alignment within ±0.1 mm, causing 12% power leakage

• Chlorine-Based Cleaners: 100 ppm chlorine residue accelerates corrosion, reducing waveguide lifespan by 60–70%

• Non-Lint Cloths: >5 µm fiber debris causes arcing at >3 kW power levels

For optimal results, follow these cleaning parameters based on waveguide type:

| Waveguide Material | Safe Cleaner Type | Concentration (%) | Max Pressure (PSI) | Contact Time (min) | Dry Time (min) |

|---|---|---|---|---|---|

| Silver-Plated Copper | Acetic Acid Solution | 3–5 | 15 | 2–3 | 5–10 |

| Bare Aluminum | Isopropyl Alcohol (99%) | 100 | 10 | 1–2 | 3–5 |

| Gold-Plated Brass | Ammonia Solution | 2–4 | 8 | 1.5–2.5 | 8–12 |

| Stainless Steel | Ethanol Solution | 70–80 | 20 | 3–4 | 2–4 |

Proper cleaning requires specific tools and sequences. Use lint-free swabs with <3 µm fiber size and ph-neutral cleaners with <50 ppm impurity levels. For persistent contaminants, apply 5% acetic acid solution at 25–30°C for maximum 3 minutes, followed by deionized water rinse with 18 MΩ·cm resistivity. After cleaning, purge with dry nitrogen at 5–10 PSI for 2–3 minutes to prevent water spots. Measure results with surface roughness tester ensuring <0.2 µm Ra and use VNA verification confirming VSWR <1.25:1. In one documented case, switching from abrasive pads to ultrasonic cleaning at 40 kHz reduced maintenance costs by $1,200 annually and extended waveguide life by 8 years. Always store cleaned waveguides in <40% RH environments with desiccant packs to prevent recontamination.