Waveguides can overheat in high-power applications (>100W), as dielectric/conductor losses convert RF energy to heat. For example, a WR-90 copper waveguide at 10 GHz loses ~0.5 dB/m (~10% power), raising temperatures by 10–20°C per meter. Uncooled systems may reach 60–80°C, risking deformation; active cooling (fans/liquid) maintains safe operation below 100°C.

Table of Contents

Waveguide Basics and Heat

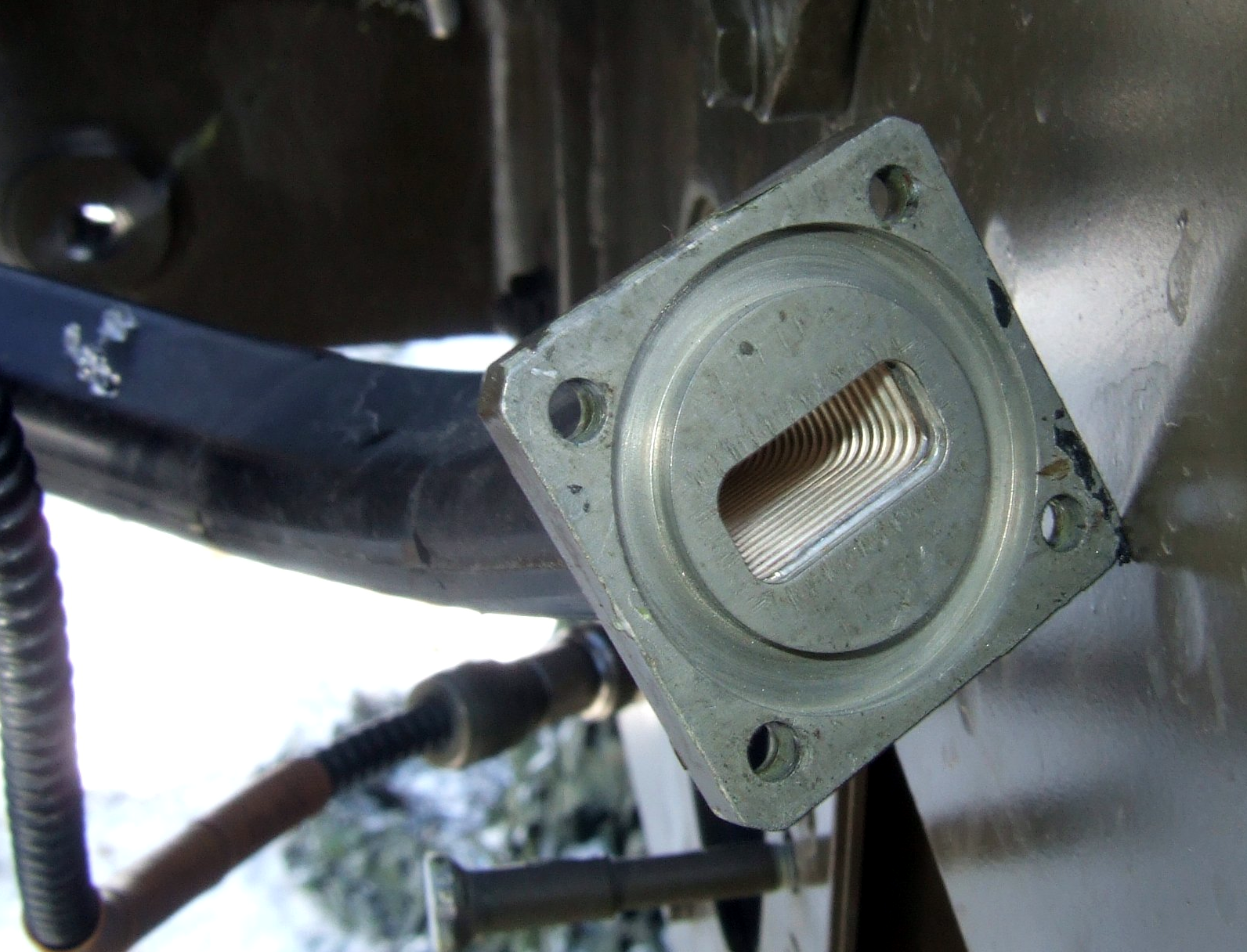

They are essentially hollow, metal pipes, often rectangular or circular, that function as conduits for high-frequency signals, typically above 1 GHz. A common question from engineers and system designers is whether these passive structures generate heat during operation. The direct answer is yes, but the extent of heating is not due to the waveguide itself being an active source. Instead, heat generation is a secondary effect primarily caused by ohmic losses within the metal walls. When a strong RF signal, say a 10 kW microwave signal at 2.45 GHz, travels through a standard rectangular WR-340 waveguide made of aluminum, a small portion of its energy—often less than 0.5%—is dissipated as heat. This dissipation occurs because the electrical currents induced on the inner surface of the guide encounter the inherent resistivity of the metal.

For copper, which has a conductivity of approximately 5.96×10⁷ S/m, the loss is lower than in brass (1.5×10⁷ S/m), directly influencing the temperature rise. The surface roughness also plays a critical role; a polished inner surface with an average roughness of less than 0.1 µm can reduce losses by up to 15% compared to a rough surface, thereby limiting heat buildup. Furthermore, the physical size of the waveguide dictates the power handling capacity; a larger cross-section, like WR-975 (9.75 x 4.875 inches), can handle multiple megawatts of power with negligible temperature increase in well-designed systems, while a smaller WR-90 guide might show a noticeable 10-20°C temperature rise when continuously transmitting 2 kW of power at 10 GHz.

The primary mechanism for heat generation in a waveguide is I²R loss from currents flowing on its inner walls, with the amount of heat being directly proportional to the square root of the operating frequency and the square of the current.

For instance, a circular waveguide operating at 30 GHz may experience an attenuation of around 0.05 dB/m, which translates to about 1.15% of the power being lost per meter and converted to heat. This is why waveguides for high-frequency applications are often shorter in length and may employ more expensive, low-loss materials like silver-plating, which can reduce attenuation by an additional 5-8%. The mode of propagation is another critical factor. The dominant TE₁₀ mode in rectangular guides has a specific current distribution pattern, with the highest current density—and thus the greatest ohmic loss—concentrated along the center of the broader wall. This can create localized hot spots if the guide is subjected to high average power over extended periods, such as 30 minutes of continuous operation with 50 kW of pulsed power.

For a system designer, calculating the power capacity is vital. A common rule of thumb is that the maximum average power handling of an air-filled waveguide is limited by its potential for voltage breakdown, which is roughly 30 kV/cm for dry air, and its thermal dissipation capabilities. A large, aluminum waveguide might safely handle 100 kW of average power at 3 GHz with forced air cooling, maintaining an external surface temperature below 50°C in a 25°C ambient environment. Without any cooling, the same guide could see temperatures rise to over 70°C, potentially affecting system performance and material integrity.

Metal Type and Heat

For instance, the inherent conductivity of copper (5.96×10⁷ Siemens/meter) results in up to 40% lower losses for the same frequency and power level compared to aluminum (3.77×10⁷ S/m). This difference directly translates to a measurable reduction in heat generation, making copper the preferred material for high-power, high-efficiency systems where even a 1% loss reduction is critical. However, aluminum’s lower density (2.7 g/cm³ vs. 8.96 g/cm³ for copper) and approximately 60% lower material cost often make it the default choice for larger, cost-sensitive systems where a slightly higher operating temperature, perhaps 5-10°C warmer, is acceptable.

The metal’s surface finish is equally vital; a smooth interior with a surface roughness under 0.1 µm can decrease resistive losses by nearly 15% by reducing the effective path length for surface currents. For extreme applications, such as satellite communications where every watt of loss matters, waveguides are often silver-plated. Silver’s higher conductivity (6.30×10⁷ S/m) can reduce attenuation by an additional 5-8% compared to copper, though this comes at a significant cost premium, sometimes increasing the component price by 200-300%.

The operational reality is that different metals will reach different steady-state temperatures under identical conditions. Consider a WR-90 waveguide handling 5 kW of continuous power at 10 GHz. An aluminum version might see a temperature rise of 45°C above ambient, reaching a surface temperature of 70°C in a 25°C environment. An identical waveguide made from copper would run approximately 12-15°C cooler under the same load due to its superior conductivity. This temperature differential isn’t just about touch; it directly impacts long-term reliability. Repeated thermal cycling between 20°C and 70°C can induce mechanical stress and fatigue in aluminum, potentially leading to joint failures over a 10-year lifespan. Copper, with its higher thermal conductivity (401 W/m·K vs. 237 W/m·K for aluminum), distributes heat more evenly, mitigating hot spots and reducing the risk of thermal deformation.

For military or aerospace systems where weight is a constraint, beryllium copper is sometimes employed. It offers about 75% of the conductivity of pure copper but with significantly higher strength and a weight nearly 20% lower than aluminum, though its material cost can be 10x higher. The decision ultimately hinges on a trade-off: maximizing electrical performance with copper or silver, minimizing weight and cost with aluminum, or seeking a specialized compromise for unique operational environments.

Frequency’s Role in Heating

Operating frequency is arguably the most dominant factor influencing heat generation in waveguides. While power level and material matter, the frequency of the transmitted signal directly dictates the intensity of resistive losses occurring on the inner surface of the guide. This is because the current responsible for these losses is concentrated within an extremely thin layer called the skin depth, which itself is inversely proportional to the square root of the frequency. For example, the skin depth in copper shrinks from about 2.1 µm at 1 GHz to just 0.66 µm at 10 GHz. This means at higher frequencies, the same current is forced to flow through a significantly smaller cross-sectional area of the metal, dramatically increasing current density and, consequently, resistive (I²R) heating. A system operating at 24 GHz can experience attenuation losses per meter that are over 400% higher than an identical system running at 6 GHz, fundamentally changing the thermal design requirements. This is why waveguides for millimeter-wave applications (e.g., E-band at 71-86 GHz) are often much shorter in length and sometimes require active cooling, even for moderate power levels below 100 watts.

The relationship between frequency and attenuation is not linear; it’s a square root function. This means that doubling the frequency increases the attenuation constant by approximately 1.414 times, all other factors being equal. For a practical engineer, this translates into a predictable temperature rise. Consider a 3-meter long, aluminum WR-90 waveguide transmitting 2 kW of power. At 5 GHz, the attenuation might be around 0.04 dB/m, leading to a total power loss of roughly 0.24 dB, or about 5.5% of the input power being converted to heat (110 watts). This might cause a manageable temperature increase of 25-30°C. However, that same guide operating at its designated cutoff of 10 GHz sees attenuation rise to nearly 0.11 dB/m. The total loss jumps to 0.33 dB, meaning over 7.5% of the power (150 watts) is now dissipated as heat, likely resulting in a 10-15°C higher operating temperature for the waveguide. This effect is so pronounced that it fundamentally limits the practical length of waveguides at high frequencies. A 10-meter run at 30 GHz could see over 15% of the power lost as heat, making it thermally and electrically inefficient compared to a series of shorter guides with amplifiers.

| Frequency (GHz) | Skin Depth in Copper (µm) | Approx. Attenuation in WR-90 (dB/m) | Power Loss for 2 kW, 3m length (Watts) |

|---|---|---|---|

| 5 | 0.93 | 0.040 | ~110 W |

| 10 | 0.66 | 0.110 | ~150 W |

| 24 | 0.43 | 0.270 | ~310 W |

This frequency-dependent loss is the primary reason why low-frequency systems (like AM radio broadcasting at 1 MHz) can use massive waveguides and run at multi-megawatt power levels with only passive cooling, while a high-frequency radar system at 35 GHz might be limited to tens of kilowatts and require precisely designed forced-air or liquid cooling loops to manage the intense, localized heating.

Power Levels and Temperature

In an ideal scenario, 100% of the input power would be transferred to the output. However, in real-world waveguides, a small but critical percentage of this power is lost to resistive heating within the metal walls. For a standard aluminum WR-430 waveguide handling 50 kW of continuous power at 2.45 GHz, this loss typically amounts to 0.3% to 0.5%, equating to 150-250 watts of energy being continuously converted into heat. This dissipated power acts as an internal heat source, causing the waveguide’s temperature to rise until it reaches a steady-state equilibrium where the heat generated equals the heat dissipated to the surrounding environment. The final temperature is not a fixed number but a result of the balance between input power, attenuation, and cooling efficiency. A system transmitting 100 kW will experience roughly double the temperature rise of a system transmitting 50 kW, assuming identical frequency and physical conditions.

For a copper waveguide operating at 10 GHz, moving from 1 kW to 5 kW of input power might increase its surface temperature from 35°C to 75°C in a 25°C ambient environment. However, pushing the same guide to 10 kW might cause the temperature to soar to 120°C, as natural convection cooling becomes less effective and the material’s thermal resistance plays a larger role. This is why average power is a more critical metric for thermal design than peak power in many applications. A radar system might transmit a 100 kW peak power pulse with a 0.1% duty cycle, resulting in an average power of just 100 watts. This would generate significantly less heat than a communications system continuously transmitting 5 kW. The physical size of the waveguide is the other major factor; a larger waveguide has a greater surface area for heat dissipation.

| Input Power (kW) | Avg. Power Loss in Aluminum WR-430 @ 2.45 GHz (Watts) | Approx. Temp. Rise (°C) with Natural Convection | Approx. Steady-State Surface Temp. (@ 25°C Ambient) |

|---|---|---|---|

| 10 | ~40 W | 15-20°C | 40-45°C |

| 50 | ~200 W | 55-65°C | 80-90°C |

| 100 | ~400 W | 95-110°C | 120-135°C |

For high-power systems exceeding 50 kW of average power, active cooling becomes non-negotiable. Forced air cooling, with air flowing at 10-20 cubic meters per hour, can reduce the steady-state temperature of a waveguide by 30-40% compared to passive cooling alone. In extreme cases, such as particle accelerator applications using multi-megawatt pulses, water cooling channels are machined directly into the waveguide walls.

This aggressive cooling can maintain the copper surface below 50°C even with an average power density exceeding 500 watts per centimeter of guide length. The ultimate limit is often the power handling capacity, determined by the potential for voltage breakdown (approximately 30 kV/cm in dry air) and the melting point of the materials. Exceeding these limits, even for a millisecond, can cause permanent deformation or catastrophic failure. Therefore, accurately calculating the thermal load based on input power, frequency, and material is the first and most important step in ensuring system longevity.

Measuring Waveguide Temperature

Accurately determining the surface temperature of an operating waveguide is critical for system performance and safety, yet it presents unique challenges due to high electromagnetic fields and often inaccessible installation points. Unlike measuring a static object, a live waveguide combines extreme RF environments with the need for precision, as a 20°C error in reading could mask a dangerous thermal overload condition. For a high-power radar system transmitting 500 kW peak power, the waveguide surface can experience rapid temperature fluctuations exceeding 80°C per minute during transmission bursts. Standard contact methods like thermocouples can interfere with RF performance, while non-contact infrared (IR) sensors must be carefully selected to account for the emissivity of the metal surface, which for polished aluminum is typically around 0.05, leading to significant measurement errors if not calibrated. Modern approaches often use fiber optic temperature probes, which are immune to EMI and offer accuracies within ±0.5°C, but at a cost of 500−1000 per sensor point, making them suitable for critical, high-value systems.

The selection of a measurement method depends entirely on the operational parameters. For lower-power systems under 10 kW, a simple Type K thermocouple attached with high-temperature epoxy can provide a reliable reading with a response time of 200-500 milliseconds. However, its metallic nature can slightly perturb the electromagnetic field, potentially increasing local loss by 1-2%. For systems operating above 18 GHz, even a small perturbation can cause measurable VSWR degradation. In these scenarios, non-contact IR thermometers are preferred. Their accuracy, however, is entirely dependent on correctly setting the emissivity value. A polished brass waveguide has an emissivity of roughly 0.1, while an oxidized brass surface can have an emissivity of 0.6. Failing to adjust for this can result in a measurement error of 40°C or more when measuring a surface at 120°C. For the most critical measurements, such as monitoring a 100 kW satellite uplink waveguide, fiber optic sensors are the gold standard. They provide a complete EMI-free environment and can be embedded within a waveguide assembly to measure the inner wall temperature directly, with a precision of ±0.3°C over a range from -40°C to 250°C.

- Thermocouples (Type K): Best for under 10 kW systems. Low cost (20−50). Accuracy: ±1.5°C to ±2.5°C. Risk of field perturbation.

- Infrared Sensors: Essential for high-frequency or high-power (>50 kW) systems. Cost: 200−800. Accuracy: Highly dependent on emissivity setting; can be ±1% of reading if properly configured.

- Fiber Optic Probes: Used in high-EMI or mission-critical applications. Cost: 500−1500. Accuracy: ±0.3°C to ±0.5°C. No RF interference.

The highest temperature on a rectangular waveguide run will typically be found at the center of the broad wall, 30-40% of the way along its length from the input, where heat accumulation peaks. For a 6-meter long guide, the hot spot might be 2.5 meters from the source. Continuous monitoring systems should sample temperature at a rate of at least 10 Hz to capture transient thermal spikes from power surges. All measurement data must be logged and correlated with forward power levels. A sudden 15% increase in temperature for the same power input often indicates a developing fault, such as internal corrosion increasing surface resistance or a failing cooling system, allowing for predictive maintenance before a catastrophic failure occurs.

Cooling Waveguides in Systems

Passive cooling, which relies on natural convection and radiation, has clear limits; it can typically dissipate only about 0.8 W/cm² per degree Celsius of temperature difference for a bare aluminum surface. This means a 2-meter long WR-90 waveguide with a surface area of roughly 600 cm² might only shed 50 watts of heat with a 10°C temperature rise, making it unsuitable for high-power applications. When power losses exceed 100 watts, active cooling systems become mandatory to prevent thermal damage. These systems work by dramatically increasing the heat transfer coefficient. Forced air cooling can achieve coefficients of 25-100 W/m²·K, while liquid cooling can reach 500-10,000 W/m²·K, allowing them to manage heat loads that are orders of magnitude greater. The choice between methods involves a direct trade-off between cooling performance, system complexity, and cost, with even basic forced air systems adding 200−500 to the bill of materials for a typical radar cabinet.

For the majority of systems operating between 5 kW and 50 kW, forced air cooling is the most cost-effective solution. A typical setup uses a 24 VDC axial fan delivering 100-150 cubic feet per minute (CFM) of air across the waveguide surface. This airflow can increase the effective heat dissipation by 300-400% compared to passive cooling alone, often reducing the steady-state operating temperature by 30-40°C. For a waveguide running at 70°C passively, a well-directed air stream can bring it down to a safer 40-45°C. The design is critical; airflow must be laminar and directed at the hot spots, usually the center of the broad wall. Systems often use a temperature feedback loop, where a thermistor mounted on the waveguide controls the fan speed, reducing acoustic noise and power consumption when full cooling isn’t required.

- Forced Air: Ideal for 5-100 kW systems. Cost: 200−800. Capacity: Can dissipate 150-500 watts of heat, reducing temperature by 30-50°C. Requires 50-100 W of electrical power for fans.

- Liquid Cooling: Used for >50 kW systems or compact designs. Cost: 2,000−10,000+. Capacity: Can handle 1-20 kW of heat load, maintaining temperature within 5°C of coolant temperature.

- Conduction Cooling: Used in sealed enclosures. Relies on thermal straps (e.g., copper braids) to a cold plate. Efficiency depends on contact area and pressure.

When heat loads exceed 1 kW or space is severely constrained, liquid cooling is the only viable option. This involves machining a channel (often 4 mm wide by 6 mm deep) directly into the waveguide wall or attaching a cold plate. Deionized water is the most common coolant, with a typical flow rate of 2-4 liters per minute and an inlet temperature of 20-25°C. This system can maintain the waveguide wall within 5°C of the coolant temperature, even with internal heat loads of 2000 watts per square meter. The major drawbacks are complexity and cost; a liquid cooling loop requires a pump, heat exchanger, filters, and redundant sensors, increasing the subsystem cost by thousands of dollars and requiring significant maintenance.

For the highest power applications, like particle accelerators, some designs use conduction cooling through massive copper bars, which can transport heat to a remote heat sink at a rate of 400 W per bar per 20°C temperature difference. The ultimate goal is always to select the most economical method that keeps the waveguide within its safe operating temperature, typically below 80-90°C for aluminum to avoid material softening and long-term degradation.