Waveguide Gasket, Die Cut

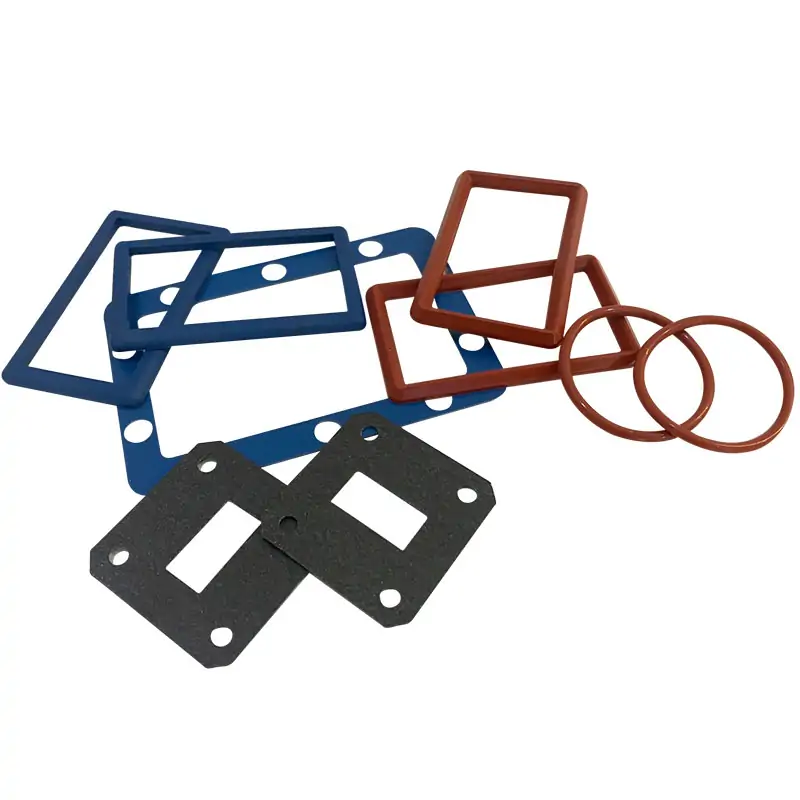

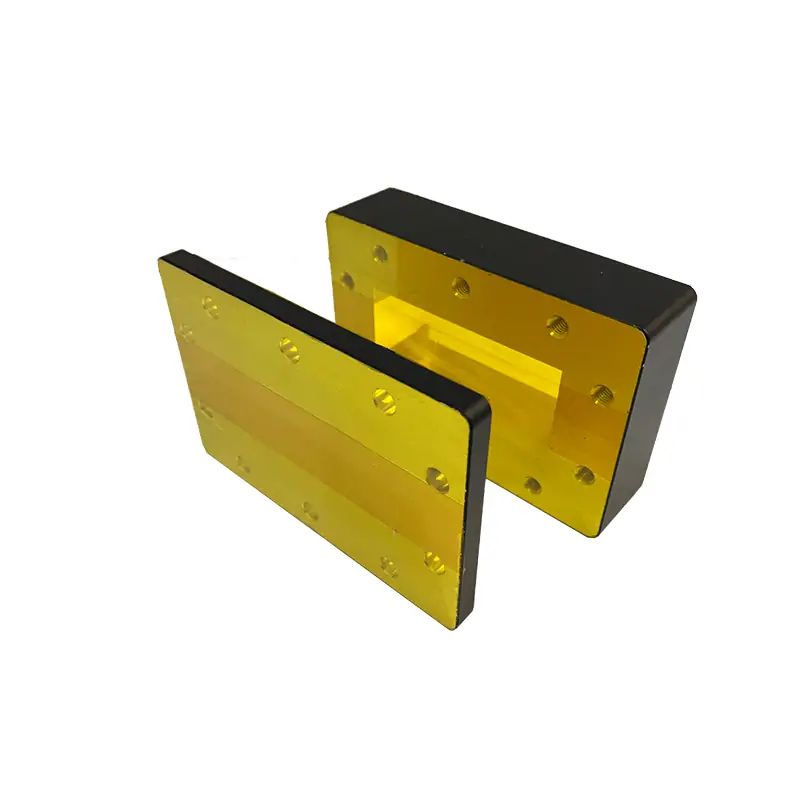

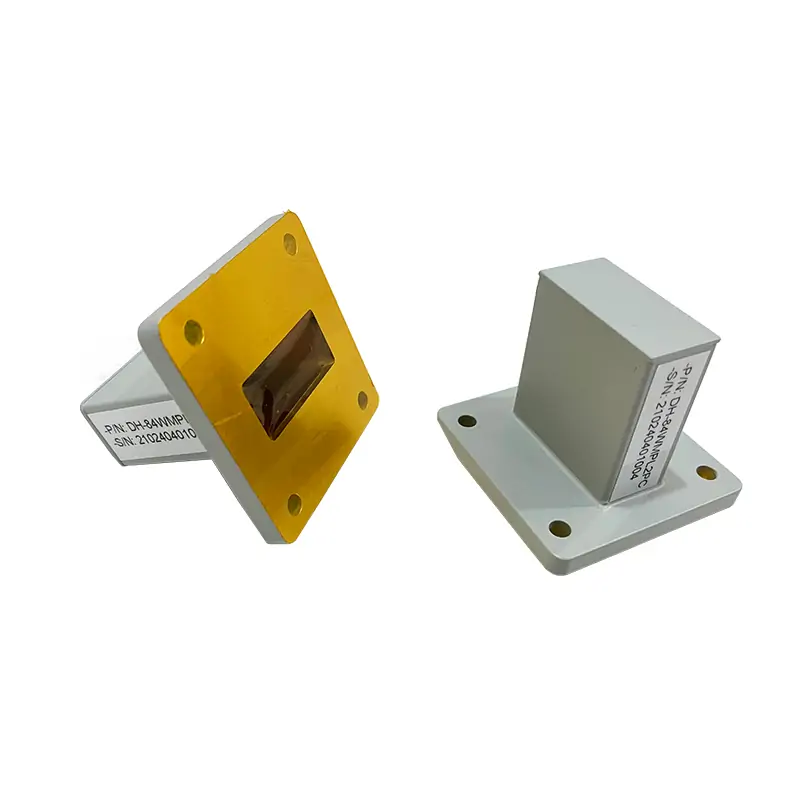

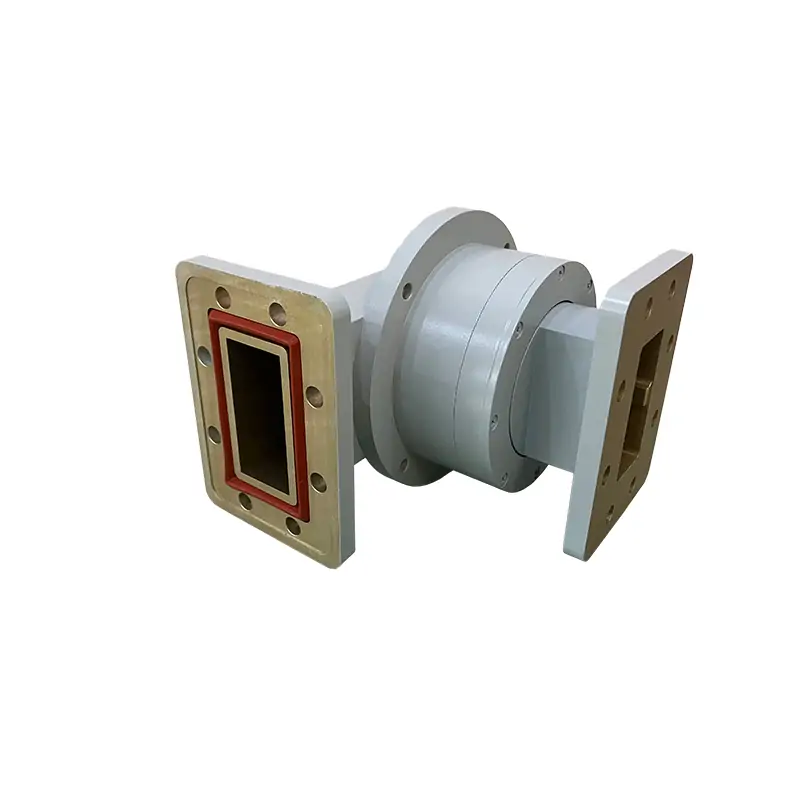

Dolph Microwave’s Waveguide Gasket, Die Cut provides precision RF/pressure sealing for WR10 to WR2300+ waveguide systems. Engineered in conductive (85 Durometer silver-copper silicone) or non-conductive materials (silicone/neoprene), these gaskets ensure EMI shielding and vacuum integrity while exceeding MIL standards for CPR, UG, CMR, and custom flanges.

Product Description:

Dolph Microwave delivers high-performance die-cut waveguide gaskets engineered for seamless connectivity in rectangular and double ridge waveguide systems. Designed to exceed MIL standards, our gaskets ensure superior EMI/RFI shielding and ultra-high vacuum (UHV) compatibility. Available in WR10 to WR2300+ sizes, they provide critical RF/pressure sealing with attenuation as low as 0.02 dB across 0.5–110 GHz bands. Engineered for aerospace, defense, and telecom applications where signal integrity is non-negotiable.

Key Product Advantages

- Material Expertise: Conductive silver-plated copper silicone (85 Durometer) for EMI shielding, plus non-conductive options (silicone/neoprene/EPDM) for pressure-only sealing.

- Universal Flange Compatibility: CPR, UG, CMR, UDR, UAR, PBR, and custom flange designs (IEC/EIA standards).

- Critical Environment Ready: Withstands UHV conditions (-10⁹ Torr), extreme temperatures (-55°C to +200°C), and vibration.

- Dual-Function Sealing: Choose conductive gaskets (RF + pressure seal) or non-conductive (pressure-only O-rings/half-gaskets).

- Reduced Height Support: Specialized solutions for half-height/reduced waveguide configurations.

Industry Applications

Deployed in mission-critical systems requiring zero RF leakage:

- Military radar & satellite communications

- Aerospace avionics testing

- Particle accelerator RF systems

- Medical imaging (MRI RF coils)

- 5G/mmWave infrastructure

| MODEL | WG SIZE | THICKNESS (mm) | FLAT GASKET, DIE CUT FOR CPR/UDR, U/G, UBR, UAR STYLE FLANGES | ELECTRICAL CONDUCTIVITY | MATERIAL | ROHS/REACH | DATASHEET | |||

| DH-14WFGT1… | WR650 | 0.5 to 2 | UDR/CPR650 | Conductive | Silicone | Comply | STEP | |||

| DH-18WFGT1… | WR510 | 0.5 to 2 | UDR/CPR510 | Conductive | Silicone | Comply | STEP | |||

| DH-22WFGT1… | WR430 | 0.5 to 2 | UDR/CPR430 | Conductive | Silicone | Comply | STEP | |||

| DH-26WFGT1… | WR340 | 0.5 to 2 | UDR/CPR340 | Conductive | Silicone | Comply | STEP | |||

| DH-32WFGT1… | WR284 | 0.5 to 2 | UAR32 | UDR/CPR284 | Conductive | Silicone | Comply | STEP | ||

| DH-40WFGT1… | WR229 | 0.5 to 2 | UAR40 | UDR/CPR229 | Conductive | Silicone | Comply | STEP | ||

| DH-48WFGT1… | WR187 | 0.5 to 2 | UAR48 | UDR/CPR187 | Conductive | Silicone | Comply | STEP | ||

| DH-58WFGT1… | WR159 | 0.5 to 2 | UAR58 | UDR/CPR159 | Conductive | Silicone | Comply | STEP | ||

| DH-70WFGT1… | WR137 | 0.5 to 2 | UAR70 | UDR/CPR137 | Conductive | Silicone | Comply | STEP | ||

| DH-84WFGT1… | WR112 | 0.5 to 2 | UG/UBR84 | UDR/CPR112 | Conductive | Silicone | Comply | STEP | ||

| DH-100WFGT1… | WR90 | 0.5 to 2 | PBR100 | UDR/CPR90 | Conductive | Silicone | Comply | STEP | ||

| DH-120WFGT1… | WR75 | 0.5 to 2 | PBR120 | UDR/CPR75 | Conductive | Silicone | Comply | STEP | ||

| DH-140WFGT1… | WR62 | 0.5 to 2 | PBR140 | Conductive | Silicone | Comply | STEP | |||

| DH-180WFGT1… | WR51 | 0.5 to 2 | PBR180 | Conductive | Silicone | Comply | STEP | |||

| DH-220WFGT1… | WR42 | 0.5 to 2 | PBR220 | Conductive | Silicone | Comply | STEP | |||

| DH-260WFGT1… | WR34 | 0.5 to 2 | PBR260 | Conductive | Silicone | Comply | STEP | |||

| DH-320WFGT1… | WR28 | 0.5 to 2 | PBR320 | Conductive | Silicone | Comply | STEP | |||

| Part Number Guide: DH-100WFGT1DC-873 "100"—Waveguide Size | WR90 "WFG"—Gasket Type | Waveguide Flat Gasket "T1"—Thickness | 1 mm, or customer to specify thickness "D/B"—Flanges Style | Rectangle/Square "C-873"— Electrical Conductiovity | Conductive Materials |

||||||||||

| Note: PRESSURE SEAL; or PRESSURE and RF SEAL ? @If a Pressure seal only, then use a NON-CONDUCTIVE Gasket. These are usually Silicon or Neoprene material, O-rings or Rectangles, designed to fit into flange grooves. @If a Pressure and RF seal is required, then use a CONDUCTIVE Gasket. These look similar to the non-conductive gaskets, but are filled with a conductive material, usually copper or silver. The exception is the Die-cut Gasket, which resembles the flange face. |

||||||||||