Seamless Flexible WG

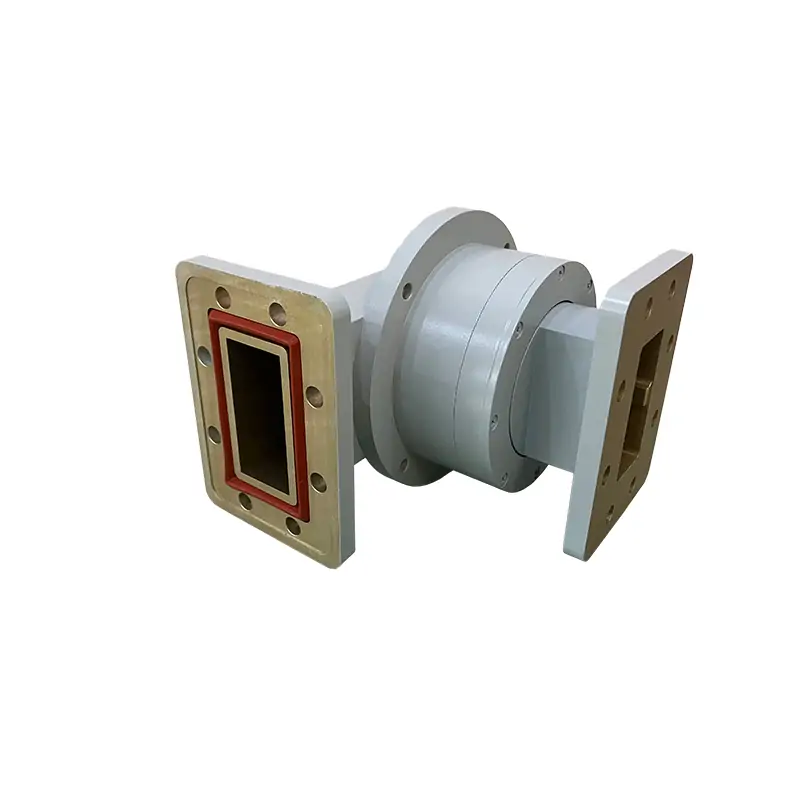

Dolph-MW Seamless Flexible Waveguides provide essential low-loss RF signal paths for demanding satcom, radar, and telecom systems. Engineered with helically wound silver-plated copper alloy cores and protective neoprene jackets, they enable reliable E- & H-plane bending (-20°C to +100°C) and feature customizable brass/aluminum flanges for critical alignment.

Product Description:

Dolph-MW Seamless Flexible Waveguides are essential components engineered for high-frequency signal transmission in demanding satcom, VSAT, telecom, radar, and aerospace systems. Constructed from helically wound silver-plated copper alloy for exceptional conductivity and flexibility, these waveguides provide low insertion loss (as low as 0.12 dB/m), maintain high air tightness, and withstand pressures up to 30 PSIG. Their robust neoprene rubber jacket ensures reliable operation across an extensive temperature range (-20°C to +100°C), making them ideal for critical connectivity requiring complex routing.

Key Features & Advantages:

- Seamless Helical Construction: Made from silver-plated copper alloy (Brass or BeCu) wound helically, ensuring superior electrical performance and eliminating leakage paths for maximum reliability in high-power applications (up to 20 kW).

- Dual-Plane Flexibility: Engineered to bend seamlessly in both the E-plane and H-plane, facilitating easy installation and alignment in confined spaces where rigid waveguides are impractical.

- Extended Operational Range: Features a durable molded neoprene rubber or silicone jacket protecting the core across a wide thermal range (-20°C to +100°C) and harsh environments.

- Broad Frequency Spectrum: Covers frequencies from approximately 1.13 GHz (WR-650) to 50.1 GHz (WR-22), supporting virtually all high-frequency radio applications.

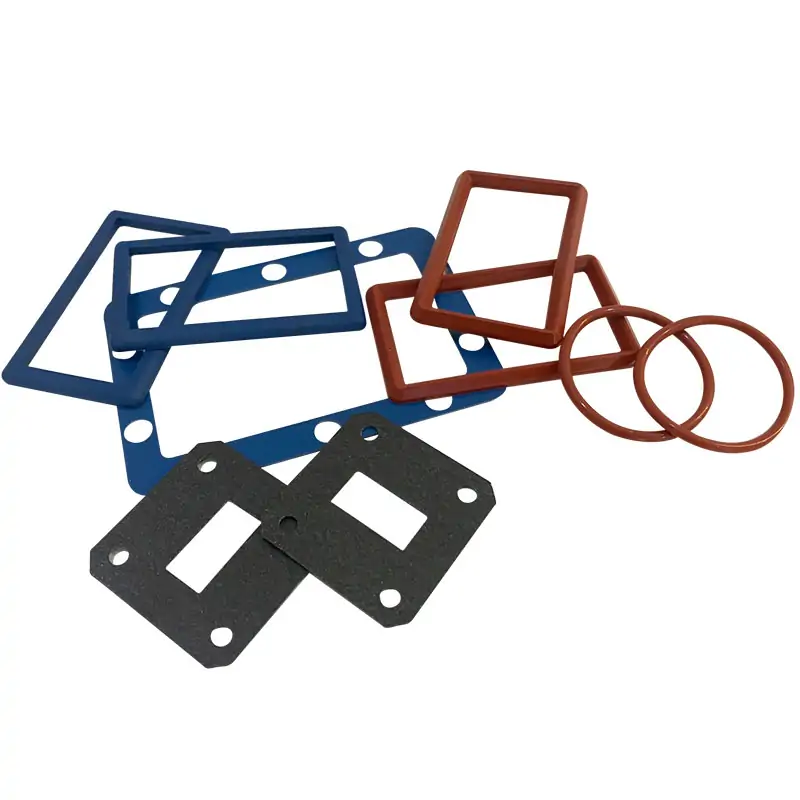

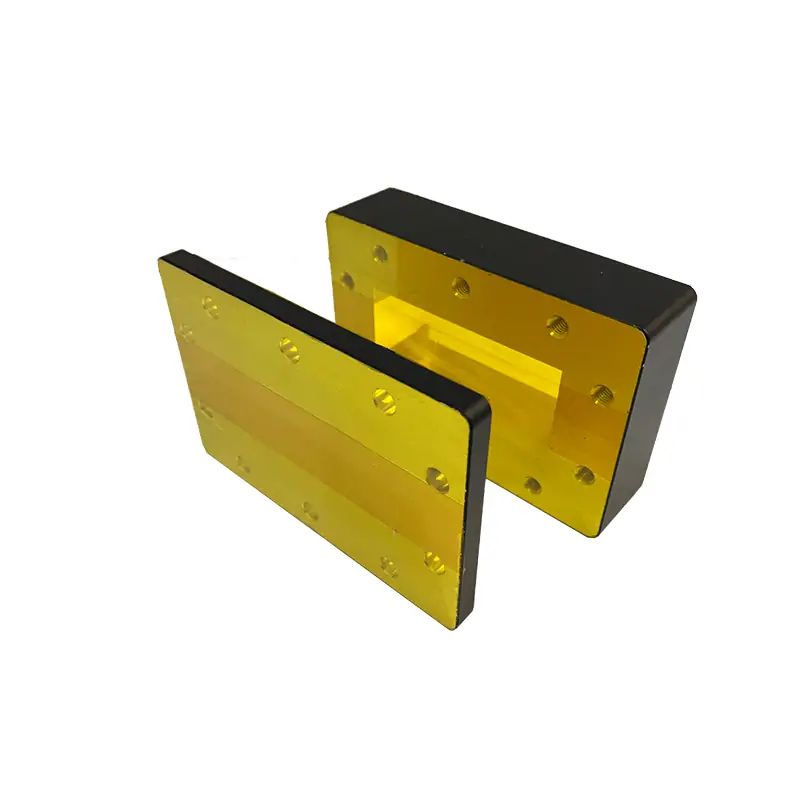

- Rigorous Testing & Customization: Each unit is pressure-tested and tuned for optimal performance. Extensive customization includes flange material choice (Brass or Aluminum 6061), plating options (Silver, Nickel, Cadmium, Tin, Gold), jacket finishes (Flat Black Paint, Rubberized Paint, Neoprene), and flange configurations complying with both North American (e.g., UDR, PDR) and European (e.g., UBR, PBR) standards.

- Reduced Lead Time: In-house flange manufacturing capabilities enable quick delivery of both standard and custom flange designs (flat or grooved).

Primary Applications:

- Radar Systems & Satellite Communication (Satcom) Ground Stations

- VSAT Terminals & Telecom Infrastructure

- Microwave Measurement and Precision Test Equipment

- Aerospace, Defense, and Secure Communications Platforms

- Industrial Microwave Heating & Medical Imaging Systems

- High-Power Microwave Transmission Lines

| MODEL | FREQ RANGE (GHz) | WG SIZE | VSWR | IL (dB/m) | AVG POWER (KW) | MAX. PRESSURE (PSIG) | FLANGES TYPE | CORE MATERIAL | JACKET TYPE | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-14WWEL… | 1.13-1.73 | WR650 | 1.1:1 | 0.12 | 20 | 30 | UDR14 | PDR14 | Brass / BeCu | Silicone | STEP | |

| DH-22WWEL… | 1.72-2.61 | WR430 | 1.1:1 | 0.15 | 20 | 30 | UDR22 | PDR22 | Brass / BeCu | Silicone | STEP | |

| DH-26WWEL… | 2.17-3.3 | WR340 | 1.1:1 | 0.15 | 20 | 30 | UDR26 | PDR26 | Brass / BeCu | Silicone | STEP | |

| DH-32WWEL… | 2.6-3.95 | WR284 | 1.1:1 | 0.15 | 10 | 30 | UDR32 | PDR32 | Brass / BeCu | Silicone | STEP | |

| DH-40WWEL… | 3.22-4.9 | WR229 | 1.1:1 | 0.17 | 8 | 30 | UDR40 | PDR40 | Brass / BeCu | Silicone | STEP | |

| DH-48WWEL… | 3.94-5.99 | WR187 | 1.1:1 | 0.24 | 6.5 | 30 | UDR48 | PDR348 | Brass / BeCu | Silicone | STEP | |

| DH-58WWEL… | 4.64-7.05 | WR159 | 1.1:1 | 0.22 | 6 | 30 | UDR58 | PDR58 | Brass / BeCu | Silicone | STEP | |

| DH-70WWEL… | 5.38-8.17 | WR137 | 1.1:1 | 0.25 | 5 | 30 | UDR70 | PDR70 | Brass / BeCu | Silicone | STEP | |

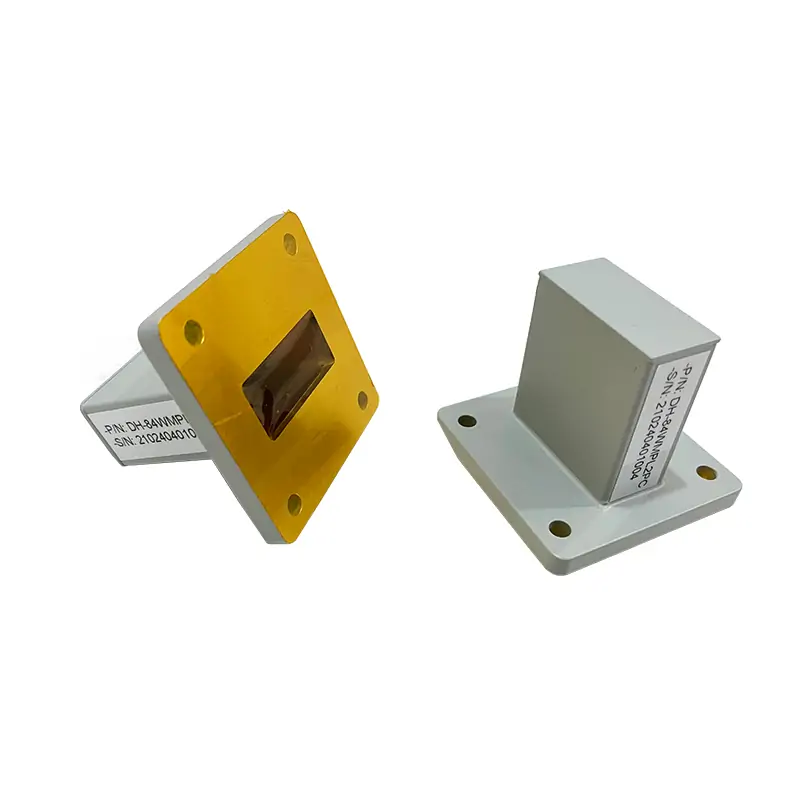

| DH-84WWEL… | 6.57-9.99 | WR112 | 1.1:1 | 0.3 | 4 | 30 | UDR84/UBR84 | PDR84/PBR84 | Brass / BeCu | Silicone | STEP | |

| DH-100WWEL… | 8.2-12.5 | WR90 | 1.1:1 | 0.4 | 3 | 30 | UDR100/UBR100 | PDR100/PBR100 | Brass / BeCu | Silicone | STEP | |

| DH-120WWEL… | 9.84-15 | WR75 | 1.15:1 | 0.5 | 1.5 | 30 | UBR120 | PBR120 | Brass / BeCu | Silicone | STEP | |

| DH-140WWEL… | 11.9-18 | WR62 | 1.15:1 | 0.8 | 1 | 30 | UBR140 | PBR140 | Brass / BeCu | Silicone | STEP | |

| DH-180WWEL… | 14.5-22 | WR51 | 1.15:1 | 1.1 | 0.5 | 30 | UBR180 | PBR180 | Brass / BeCu | Silicone | STEP | |

| DH-220WWEL… | 17.6-26.7 | WR42 | 1.2:1 | 1.2 | 0.3 | 30 | UBR220 | PBR220 | Brass / BeCu | Silicone | STEP | |

| DH-260WWEL… | 21.7-33 | WR34 | 1.25:1 | 1.5 | 0.2 | 30 | UBR260 | PBR260 | Brass / BeCu | Silicone | STEP | |

| DH-320WWEL… | 26.3-40 | WR28 | 1.3:1 | 2 | 0.15 | 30 | UBR320 | PBR320 | Brass / BeCu | Silicone | STEP | |

| DH-400WWEL… | 32.9-50.1 | WR22 | 1.3:1 | 2.7 | 0.05 | 30 | FUGP400/UG-383U/M | Brass / BeCu | Silicone | STEP | ||

| Part Number Guide: DH-100WWEL300PMA "100"—Waveguide Size | WR90 "WWWEL"—Waveguide Type | Seamless Flexible Waveguide "300"— Length | 300 mm "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "C"— Material | Cu |

||||||||||||

| Note: Available Preformed bend and hybrid flexible waveguide assemblies. Length of Seamless Flexible Assemblies The standard recommended length for the various waveguide sizes. MM: 300, 500, 600, 900, 1000, 1200 and 1500. Other lengths may be available on request but may be subject to tooling and design charges. Accessories Hardware, fixing and clamping kit accessories are available for use with our flexible waveguide products. |

||||||||||||