High Power Waveguide Rotating Joint

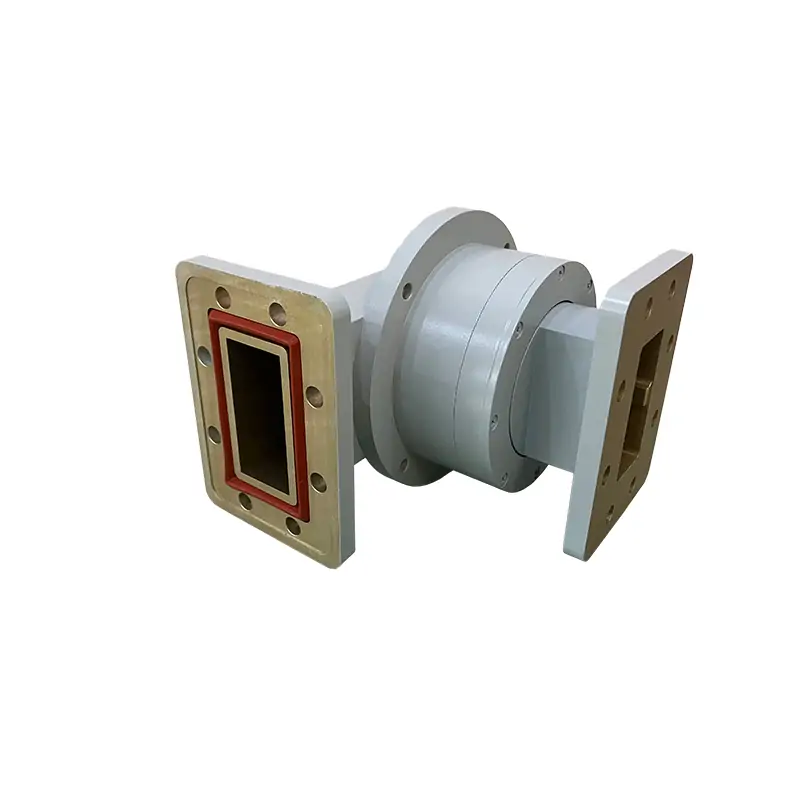

Dolph Microwave High Power Waveguide Rotating Joint enables seamless transfer of high-power RF signals (up to 12,000 Watts at S-band) between stationary and rotating assemblies in critical radar and satellite systems. Engineered with double bearings, precision seals (IP65 rating), and ≤ 0.2 dB insertion loss, it ensures exceptional performance, durability, and reliability across 1.72 to 40.0 GHz frequencies.

Product Overview:

Dolph Microwave’s High Power Waveguide Rotary Joints are precision-engineered components critical for the seamless transmission of RF energy between stationary and rotating platforms within demanding radar systems and satellite communication antennas. Engineered to operate under rigorous conditions, these joints ensure continuous signal integrity and power transfer essential for modern phased array radars, satcom terminals, and electronic warfare systems. Designs undergo rigorous simulation and physical testing, including verification at maximum peak power levels prior to delivery.

Key Features & Engineering Excellence:

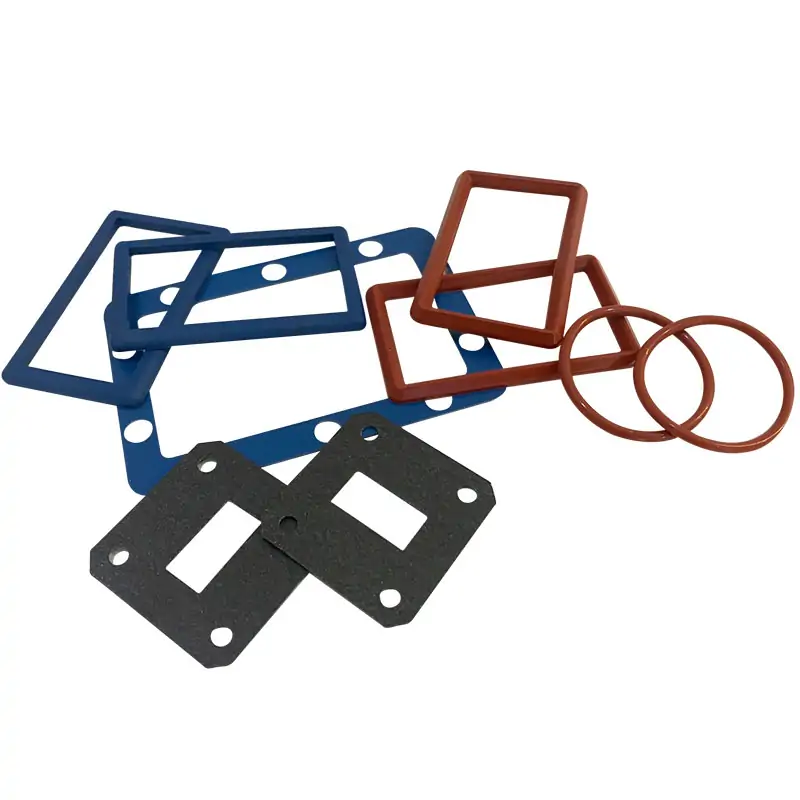

- Robust Power Handling: Specifically engineered for pressurized waveguide systems demanding maximum power transfer. Designs incorporate features like double-bearing assemblies and precision-engineered seals, ensuring reliable operation and maintaining pressurization integrity even under high continuous (CW) and peak power loads (e.g., 12 kW average at 2 GHz down to 300 W at 40 GHz as per datasheet).

- Minimal Insertion Loss: Optimized transmission paths yield insertion loss as low as 0.2 dB across the operational band (reference datasheet VSWR/IL specs), significantly boosting system signal-to-noise ratio (SNR) and radar detection range.

- High Channel Isolation: Provides effective isolation between channels, minimizing interference and crosstalk crucial for multi-functional or multi-channel systems.

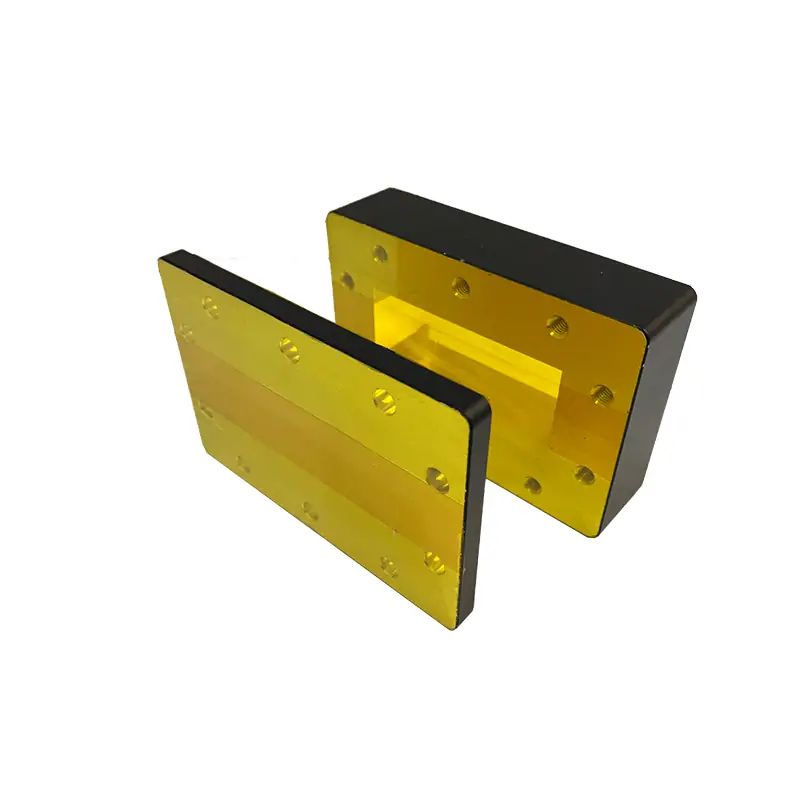

- Enhanced Durability & Longevity: Built for critical, high-duty-cycle applications. The combination of robust materials (Aluminum or Copper alloy), advanced bearing designs, and corrosion-resistant finishes (standard chromate conversion plus painted flat black) ensures exceptional operational lifespan and reliability in harsh environments.

- Versatile Configurations: Available in standard U-Style (90° bend), L-Style, and In-line orientations (indicated by the I/L/U suffix in the model number) to accommodate diverse mechanical and waveguide routing requirements.

- Environmental Protection: Standard IP65 rating ensures protection against dust ingress and water jets, suitable for demanding operational environments.

Primary Applications:

These high-performance rotary joints are indispensable in systems where uninterrupted rotation and reliable high-power RF transmission are paramount:

- Phased Array & Surveillance Radar Systems (Ground-based, Naval, Airborne)

- Satellite Communication (SATCOM) Earth Station Antennas (Tracking antennas, VSAT)

- Electronic Warfare (EW) and Signal Intelligence (SIGINT) Platforms

- Aerospace & Defense Systems (Missile seekers, airborne radar)

- High-Power Wireless Testing Equipment (ATE systems, anechoic chambers)

- Advanced Medical Imaging Equipment (e.g., high-field MRI requiring rotational components)

| MODEL | FREQ RANGE (GHz) | OPERATING BW | VSWR (Max) | IL(dB) (Max) | AVG. POWER (W) | FLANGES TYPE | INGRESS PROTECTION | MATERIAL | FINISH | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-22WHPJI | 1.72-2.61 | 10% | 1.15:1 | 0.2 | 12000 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-22WHPJL | 1.72-2.61 | 10% | 1.15:1 | 0.2 | 12000 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-22WHPJU | 1.72-2.61 | 10% | 1.15:1 | 0.2 | 12000 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-32WHPJI | 2.60-3.95 | 10% | 1.15:1 | 0.2 | 10000 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-32WHPJL | 2.60-3.95 | 10% | 1.15:1 | 0.2 | 10000 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-32WHPJU | 2.60-3.95 | 10% | 1.15:1 | 0.2 | 10000 | UDR32 | PDR32 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-40WHPJI | 3.22-4.90 | 10% | 1.15:1 | 0.2 | 3000 | UDR40 | PDR40 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-40WHPJL | 3.22-4.90 | 10% | 1.15:1 | 0.2 | 3000 | UDR40 | PDR40 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-40WHPJU | 3.22-4.90 | 10% | 1.15:1 | 0.2 | 3000 | UDR40 | PDR40 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-48WHPJI | 3.94-5.99 | 10% | 1.15:1 | 0.2 | 3000 | UDR48 | PDR348 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-48WHPJL | 3.94-5.99 | 10% | 1.15:1 | 0.2 | 3000 | UDR48 | PDR348 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-48WHPJU | 3.94-5.99 | 10% | 1.15:1 | 0.2 | 3000 | UDR48 | PDR348 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-58WHPJI | 4.64-7.05 | 10% | 1.15:1 | 0.2 | 3000 | UDR58 | PDR58 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-58WHPJL | 4.64-7.05 | 10% | 1.15:1 | 0.2 | 3000 | UDR58 | PDR58 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-58WHPJU | 4.64-7.05 | 10% | 1.15:1 | 0.2 | 3000 | UDR58 | PDR58 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-70WHPJI | 5.38-8.17 | 10% | 1.15:1 | 0.2 | 2000 | UDR70 | PDR70 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-70WHPJL | 5.38-8.17 | 10% | 1.15:1 | 0.2 | 2000 | UDR70 | PDR70 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-70WHPJU | 5.38-8.17 | 10% | 1.15:1 | 0.2 | 2000 | UDR70 | PDR70 | IP65 | Al/Cu | Chromate/Painted | STEP | |

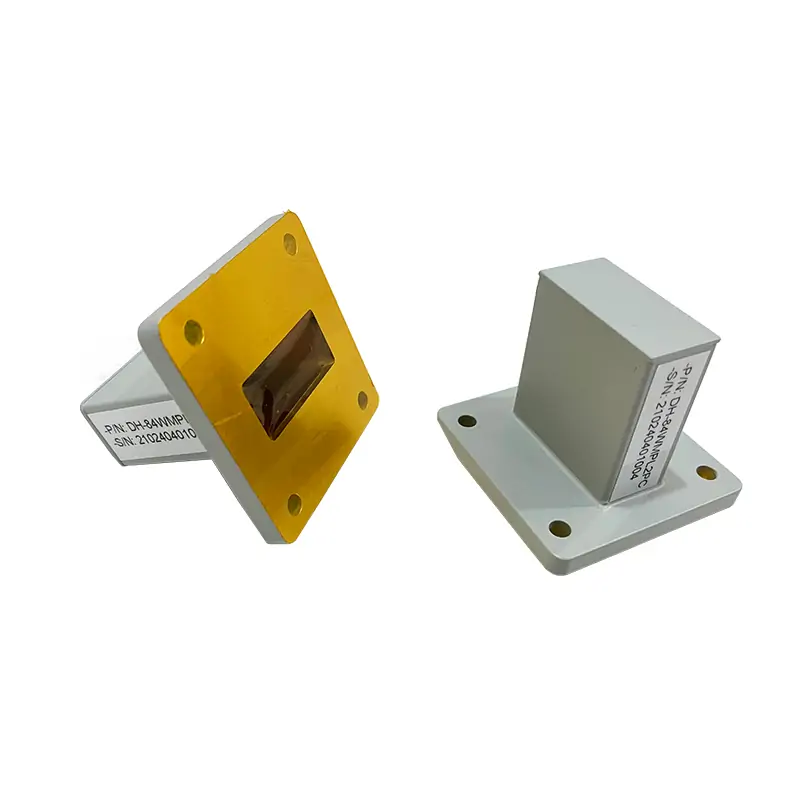

| DH-84WHPJI | 6.57-9.99 | 10% | 1.2:1 | 0.2 | 2000 | UDR84/UBR84 | PDR84/PBR84 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-84WHPJL | 6.57-9.99 | 10% | 1.2:1 | 0.2 | 2000 | UDR84/UBR84 | PDR84/PBR84 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-84WHPJU | 6.57-9.99 | 10% | 1.2:1 | 0.2 | 2000 | UDR84/UBR84 | PDR84/PBR84 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-100WHPJI | 8.20-12.4 | 10% | 1.2:1 | 0.2 | 2000 | UDR100/UBR100 | PDR100/PBR100 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-100WHPJL | 8.20-12.4 | 10% | 1.2:1 | 0.2 | 2000 | UDR100/UBR100 | PDR100/PBR100 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-100WHPJU | 8.20-12.4 | 10% | 1.2:1 | 0.2 | 2000 | UDR100/UBR100 | PDR100/PBR100 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-120WHPJI | 9.84-15.0 | 10% | 1.2:1 | 0.2 | 1000 | UBR120 | PBR120 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-120WHPJL | 9.84-15.0 | 10% | 1.2:1 | 0.2 | 1000 | UBR120 | PBR120 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-120WHPJU | 9.84-15.0 | 10% | 1.2:1 | 0.2 | 1000 | UBR120 | PBR120 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-140WHPJI | 11.9-18.0 | 10% | 1.25:1 | 0.2 | 2000 | UBR140 | PBR140 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-140WHPJL | 11.9-18.0 | 10% | 1.25:1 | 0.2 | 2000 | UBR140 | PBR140 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-140WHPJU | 11.9-18.0 | 10% | 1.25:1 | 0.2 | 2000 | UBR140 | PBR140 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-180WHPJI | 14.5-22.0 | 10% | 1.25:1 | 0.25 | 500 | UBR180 | PBR180 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-180WHPJL | 14.5-22.0 | 10% | 1.25:1 | 0.25 | 500 | UBR180 | PBR180 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-180WHPJU | 14.5-22.0 | 10% | 1.25:1 | 0.25 | 500 | UBR180 | PBR180 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-220WHPJI | 17.6-26.7 | 10% | 1.25:1 | 0.25 | 500 | UBR220 | PBR220 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-220WHPJL | 17.6-26.7 | 10% | 1.25:1 | 0.25 | 500 | UBR220 | PBR220 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-220WHPJU | 17.6-26.7 | 10% | 1.25:1 | 0.25 | 500 | UBR220 | PBR220 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-260WHPJI | 21.7-33.0 | 10% | 1.25:1 | 0.25 | 300 | UBR260 | PBR260 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-260WHPJL | 21.7-33.0 | 10% | 1.25:1 | 0.25 | 300 | UBR260 | PBR260 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-260WHPJU | 21.7-33.0 | 10% | 1.25:1 | 0.25 | 300 | UBR260 | PBR260 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-320WHPJI | 26.3-40.0 | 10% | 1.25:1 | 0.25 | 300 | UBR320 | PBR320 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-320WHPJL | 26.3-40.0 | 10% | 1.25:1 | 0.25 | 300 | UBR320 | PBR320 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-320WHPJU | 26.3-40.0 | 10% | 1.25:1 | 0.25 | 300 | UBR320 | PBR320 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| Part Number Guide: DH-100WHPJI/L/UPMA400 "100"—Waveguide Size | WHP90 "WHPJ"—Waveguide Type | High Power Waveguide Rotating Joint "I/L/U"— Joint Style | I, L, U-Shape "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu "400"— Power Rating | 400 W CW. |

||||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||||