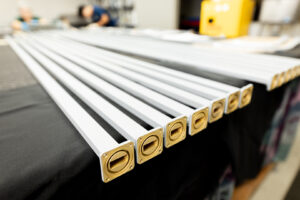

In June 2018, Dolphmicrowave participated in the development and production of 48 antenna feeds for a major national project. Including S/X/Ka Tir-band, S/X, C/Ku Dual-band, Extended frequency band and other types of antenna feeds, which are used for 16 m 9 M 7.3 m aperture antenna. It is required to complete the factory acceptance of all equipment within six months. For the satellite application department and equipment manufacturing department, it will be an unprecedented great challenge. How to accomplish this almost impossible task in a few months is a major problem facing us.

- Overall planning

When the project started, the satellite application department organized the R&D department and the production department to discuss how to complete the research and production tasks of 48 antenna feeders, and asked each department to formulate practical plans to supervise and inspect the implementation of the plans in real time. Task decomposition, layers of implementation to various departments, a large-scale campaign of coordinated cooperation among departments has begun….

- Careful design

The satellite application department organizes the design department and devotes itself to the design and Simulation of various feed systems. On the basis of mature products, the feed scheme is designed and optimized so that it can be debugged-free. In this design, the three-band feed system is designed to withstand power upgrade, And make each index better than domestic advanced level, electrical designers and structural designers cooperate with each other, in a short period of time, completed more than 10 kinds of feed design work. The manufacturing department milling 1116 waveguide elbows with 48 antenna feeds. Brazing master undertakes a large number of elbow waveguide welding work, fitter group to complete all parts assembly into products.

- Assembling test acceptance

Among the 48 sets of feeds, 8 sets of S&X&Ka three-band, 14 sets of dual-band and 26 sets of extended band totally cover. During debugging and testing, the wrench and screw fly up and down in a busy and orderly manner. Several sets of test instruments were started at the same time, and finally 48 sets of feeders were assembled and debugged. Darkroom testers succeeded in continuous work and completed the acceptance task of factory test on schedule.