Dolph Microwave is vertically integrated and mostly self-sufficient, where virtually all key processes are performed in-house, allowing for maximum control over the design and fabrication of the end product.

FABRICATION:

- CNC machining utilising high accuracy 4 and 3 Axis machines

- Lathes,Turning facilities

- Waveguide forming and bending

- Anodising and Passivation (RoHS)

- Dip, Welding, Induction & Torch Brazing

- Heat and Chemical Treating

- Rubber Molding, Painting

- Chromate Conversion

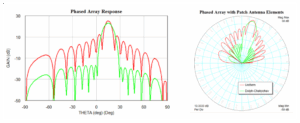

LABORATORY:

- Powerful RF vector and scalar systems up to 100 GHz

- Antenna Anechoic Chambers

- High Power Transmitters

- Environmental Testing:

- Temperature/Altitude, Salt, Fog, Humidity

- Free Space Measurement:

- Dielectric and magnetic material property characterizations

- Metamaterial characterizations (including FSS structures)

CUSTOM ABILITY:

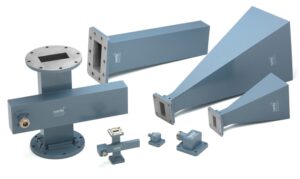

- In addition to standard products, we can make custom waveguide assemblies and sub assemblies quickly.

- Custom assemblies often involve complex bends, twists, and other special mechanical features.Contact us directly to learn more.

SERVICES:

- A team of knowledgeable sales engineers always stand ready to assist customers with standard catalog products and specialized requirements.

- Delivery for most products from stock ranges 1 – 4 weeks.

- Online Service 24/7

International Calls: +86-029-8881-0979

Skype: [email protected]

WA/Mob.: +86-177-9173-4406

Email: [email protected]