Waveguide Bends

Waveguide bends are essential components in microwave engineering, designed to redirect electromagnetic waves along a desired path within a waveguide system. They facilitate the routing of signals through complex system geometries without significant loss, making them crucial for applications in radar, telecommunications, and satellite communications. Available in various angles and sizes, waveguide bends ensure efficient signal transmission and system integration.

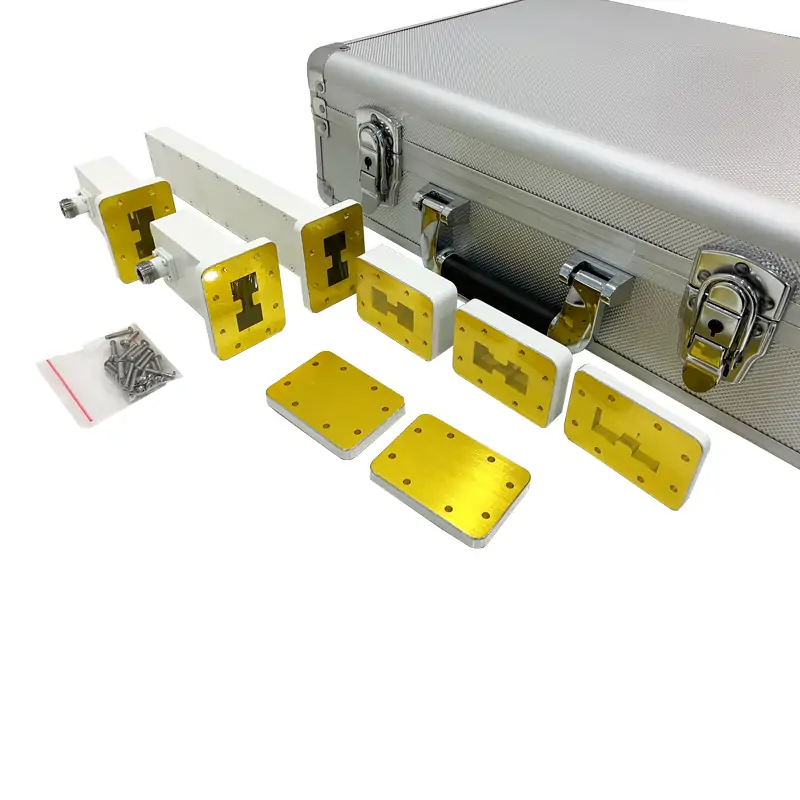

Dolph Microwave presents its comprehensive range of waveguide bends, incorporating both E-bends and H-bends designed to support frequencies from 1.72 GHz to 110 GHz. Available in sizes from WR-10 to WR-430, these waveguide bends are meticulously crafted to ensure precise bending at the desired angle while maintaining a constant cross-section. This meticulous design minimizes energy reflection, ensuring low loss and a VSWR as low as 1.06:1. Dolph Microwave’s waveguide bends are essential for high-efficiency RF, microwave, mm-wave transmissions, and are widely used in satellite and military communications, radar, telecom, instrumentation, and test benches.

Key Features

Broad Frequency Range

Supporting operations from 1.72 to 110 GHz, these waveguide bends cater to a wide variety of frequency requirements, making them suitable for a range of applications.

Low VSWR

With a maximum VSWR as low as 1.06:1 to 1.2:1, these bends ensure minimal signal reflection and loss, enhancing overall system performance.

Precision Machining

Each unit undergoes precision machining to ensure accurate and lasting performance, with a focus on maintaining a constant cross-section for optimal energy flow.

High-Quality Materials

Constructed from Oxygen Free Hard Copper (OFHC) or Copper Alloy, these waveguide bends offer durability and high conductivity, suitable for demanding environments.

Versatile Configurations

Available in both E-bends and H-bends configurations, providing flexibility for system design and allowing for precise directional changes in waveguide paths.

RoHS Compliant

Many models meet RoHS compliance, ensuring they meet global standards for environmental safety and sustainability.

Customization Options

In addition to standard catalog models, Dolph offers customization options including different radii, angles, lengths, and flange types to meet specific project requirements.

Application Scope

Dolph Microwave’s waveguide bends find applications in several critical areas:

- Satellite Communications: Enabling precise signal routing in satellite ground stations and uplink systems.

- Military Communications: Providing reliable and efficient signal transmission paths in military communication systems.

- Radar Systems: Supporting radar signal pathways with minimal loss and reflection for surveillance and tracking applications.

- Telecommunications: Facilitating signal routing in telecom infrastructure, ensuring integrity and efficiency.

- Instrumentation and Test Benches: Essential for accurate and reliable signal transmission in laboratory settings and test setups.

Technical Specifications

Here is an example of the technical specifications for Dolph Microwave’s waveguide bends:

| Specification | Detail |

|---|---|

| Frequency Range | 1.72 to 110 GHz |

| VSWR | As low as 1.06:1 |

| Waveguide Sizes | WR-430 to WR-10 |

| Types | E-plane and H-plane versions |

| Material | Oxygen Free Hard Copper/Copper Alloy |

| Flange Types | UG and CPR style available |

| Compliance | Many models are RoHS compliant |

Dolph Microwave’s waveguide bends are engineered to facilitate signal turns or bends without degrading transmission quality. With their precision design, broad frequency range, and high-quality construction, these bends are an indispensable component for any system requiring reliable waveguide configurations. Whether for new installations or system upgrades, Dolph’s waveguide bends ensure optimal performance and durability. For further information or to discuss custom requirements, Dolph Microwave invites you to contact their team of expert sales engineers.

| MODEL | FREQ. RANGE (GHz) | WG SIZE | VSWR | IL (dB/m) | FLANGES TYPE | STD. SIZE (A*B) mm | MATERAIL | FINISH | ROHS & REACH | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-840DRWEB… | 0.84-2.0 | WRD840 | 1.25:1 | 0.2 | FPWRD840U24 | FMWRD840U24 | 150*150 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-840DRWHB… | 0.84-2.0 | WRD840 | 1.25:1 | 0.2 | FPWRD840U24 | FMWRD840U24 | 200*200 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-150DRWEB… | 1.5-3.6 | WRD150 | 1.25:1 | 0.15 | FPWRD150D24 | FMWRD150D24 | 100*100 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-150DRWHB… | 1.5-3.6 | WRD150 | 1.25:1 | 0.15 | FPWRD150D24 | FMWRD150D24 | 150*150 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-200DRWEB… | 2.0-4.8 | WRD200 | 1.25:1 | 0.15 | FPWRD200D24 | FMWRD200D24 | 100*100 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-200DRWHB… | 2.0-4.8 | WRD200 | 1.25:1 | 0.15 | FPWRD200D24 | FMWRD200D24 | 150*150 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-250DRWEB… | 2.6-7.8 | WRD250 | 1.25:1 | 0.15 | FPWRD250D30 | FMWRD250D30 | 100*100 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-250DRWHB… | 2.6-7.8 | WRD250 | 1.25:1 | 0.15 | FPWRD250D30 | FMWRD250D30 | 150*150 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-350DRWEB… | 3.5-8.2 | WRD350 | 1.25:1 | 0.25 | FPWRD350D24 | FMWRD350D24 | 100*100 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-350DRWHB… | 3.5-8.2 | WRD350 | 1.25:1 | 0.25 | FPWRD350D24 | FMWRD350D24 | 100*100 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-475DRWEB… | 4.75-11.0 | WRD475 | 1.25:1 | 0.2 | FPWRD475D24 | FMWRD475D24 | 100*100 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-475DRWHB… | 4.75-11.0 | WRD475 | 1.25:1 | 0.2 | FPWRD475D24 | FMWRD475D24 | 100*100 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-500DRWEB… | 5.0-18.0 | WRD500 | 1.25:1 | 0.5 | FPWRD500D36 | FMWRD500D36 | 80*80 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-500DRWHB… | 5.0-18.0 | WRD500 | 1.25:1 | 0.5 | FPWRD500D36 | FMWRD500D36 | 80*80 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-580DRWEB… | 5.8-16.0 | WRD580 | 1.25:1 | 0.35 | FPWRD580D28 | FMWRD580D28 | 80*80 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-580DRWHB… | 5.8-16.0 | WRD580 | 1.25:1 | 0.35 | FPWRD580D28 | FMWRD580D28 | 80*80 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-650DRWEB… | 6.5-18.0 | WRD650 | 1.25:1 | 0.35 | FPWRD650D28 | FMWRD650D28 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-650DRWHB… | 6.5-18.0 | WRD650 | 1.25:1 | 0.35 | FPWRD650D28 | FMWRD650D28 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-700DRWEB… | 7.0-18.5 | WRD700 | 1.25:1 | 0.4 | FPWRD700D26 | FMWRD700D26 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-700DRWHB… | 7.0-18.5 | WRD700 | 1.25:1 | 0.4 | FPWRD700D26 | FMWRD700D26 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-750DRWEB… | 7.5-18.0 | WRD750 | 1.25:1 | 0.6 | FPWRD750D24 | FMWRD750D24 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-750DRWHB… | 7.5-18.0 | WRD750 | 1.25:1 | 0.6 | FPWRD750D24 | FMWRD750D24 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-110DRWEB… | 11.0-26.5 | WRD110 | 1.25:1 | 0.75 | FPWRD110C24 | FMWRD110C24 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-110DRWHB… | 11.0-26.5 | WRD110 | 1.25:1 | 0.75 | FPWRD110C24 | FMWRD110C24 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-180DRWEB… | 18.0-40.0 | WRD180 | 1.2:1 | 1.5 | FPWRD180C24 | FMWRD180C24 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| DH-180DRWHB… | 18.0-40.0 | WRD180 | 1.2:1 | 1.5 | FPWRD180C24 | FMWRD180C24 | 50*50 | Al/Cu | Chromate/Painted | Comply | STEP | |

| Part Number Guide: DH-840DRWEB150*150PMA "840DR"—Waveguide Size | WRD840 "WEB"—Waveguide Type | E-Bend Waveguide "WHB"—Waveguide Type | H-Bend Waveguide "150*150"— A*B Length | 150*150 mm "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu |

||||||||||||

| Note: Available Preformed bend and hybrid flexible waveguide assemblies. All Dolph-MW models include an iridite/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and iridited. Other finishes and paint colors are available upon request. |

||||||||||||