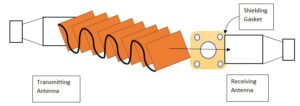

Dolph microwave offers seamless flexible/non-twistable waveguide, flexible twistable waveguide and hybrid flex/rigid waveguide assemblies from WR-22 to WR-650. and manufactured from a continuous length of thin walled copper/brass tubing. Its construction allows it to handle higher power levels than flexible twistable waveguide, and offers lower insertion and return loss.

Key features

- Flexible Twistable sizes from WR22 to WR187

- Seamless Flexible/Non-Twistable Waveguide sizes from WR28 to WR650

- Copper/Brass

- Standard North American and European Flanges

- Available with customized flanges

- Nickel, Cadmium, Tin, Silver, or Gold plated flanges

- Silver plating interior available

- Flat black paint, rubberized paint, or neoprene jacket exterior

- In-house manufacturing ensures fast delivery

- Pressure tested and tuned

Seamless Flexible/Non-Twistable Waveguide

The non-twistable cores are also silver clad and are locked by solder wire which is then melted to form a continuous fillet running the entire length of the seam. Non-twistable cores can be pressurized without an outer jacket.

The twistable cores are silver clad and are locked by a plated wire inserted into their seam during winding. An outer jacket is required to enable the twisted core to be pressurized. Flexible waveguides are manufactured from helically wound silver plated copper alloy strip material which allows the waveguides to twist and bend in the E and H planes simultaneously.

Seamless flexible/non-twistable and flexible twistable core may be used in conjunction with rigid waveguide to produce hybrid assemblies. Many of these designs may be complex Multiple bends and twists, with the flexible section Included to eliminate vibration or misalignment.

Ordering information, part numbers and more detailed specifications are available on the attached datasheet.