The IEC 60317-45 standard specifies waveguide requirements, including frequency ranges (1-110GHz) and tolerances (±0.05mm for WR-15). It defines aluminum (6061-T6) and copper (C10100) materials with surface roughness <0.8µm. Flange standards (IEC 60154-2) ensure <0.05dB insertion loss using UG-387/U interfaces. The standard covers TE10/TM11 mode operation, VSWR limits (<1.25:1), and pressure tests (up to 5 bar) for airtight sealing. Compliance ensures interchangeability across manufacturers.

Table of Contents

Waveguide Basics Explained

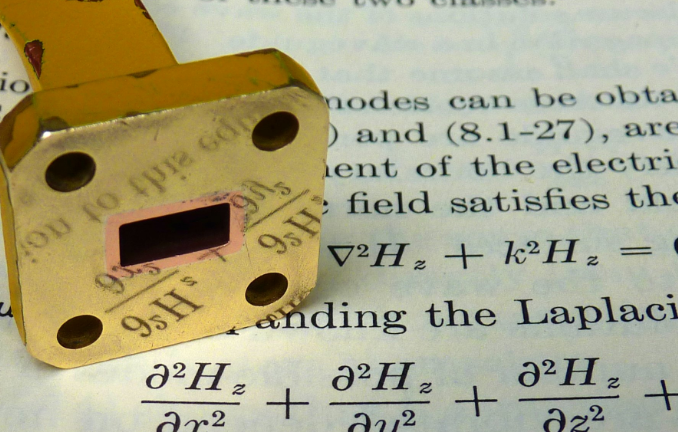

Waveguides are hollow metal tubes or dielectric structures used to transmit electromagnetic waves, primarily in microwave and radio frequency (RF) applications. Unlike traditional coaxial cables, which suffer from high signal loss above 2 GHz, waveguides offer low-loss transmission (0.1–0.3 dB/m at 10 GHz) and can handle high power levels (up to 10 kW continuous wave). The most common waveguide shapes are rectangular (e.g., WR-90, 22.86 mm × 10.16 mm) and circular, with standardized sizes defined by IEC 60153 (for metallic waveguides) and IEC 61338 (for dielectric waveguides).

Waveguides operate within cutoff frequencies, meaning they only propagate signals above a certain threshold. For example, a WR-112 waveguide (28.5 mm × 12.6 mm) has a cutoff frequency of 4.3 GHz and is typically used for 5–7.5 GHz applications. The inner surface roughness must stay below 1.6 µm to minimize signal attenuation, and materials like aluminum (loss: ~0.0003 dB/m at 10 GHz) or copper (loss: ~0.0001 dB/m at 10 GHz) are preferred for optimal performance.

| Parameter | Typical Value | Impact |

|---|---|---|

| Frequency Range | 1–110 GHz | Determines waveguide size (larger = lower freq) |

| Power Handling | 1–10 kW (CW) | Depends on material and cooling |

| Attenuation | 0.1–0.5 dB/m | Increases with frequency and surface defects |

| Impedance | ~377 Ω (TE modes) | Affects matching with RF components |

| Operating Temp | -40°C to +85°C | Aluminum expands ~23 µm/m·°C |

Waveguides are essential in radar systems (e.g., 94 GHz military radars), satellite communications (Ka-band, 26–40 GHz), and medical RF heating (2.45 GHz industrial magnetrons). Their efficiency (95–99%) surpasses coaxial cables at high frequencies, making them indispensable in 5G mmWave (24–71 GHz) and space applications.

Why Waveguides Beat Coaxial Cables at High Frequencies

At 30 GHz, a 0.141″ semi-rigid coaxial cable loses ~1.2 dB/m, while a WR-28 waveguide (7.11 mm × 3.56 mm) loses only ~0.3 dB/m. This difference becomes critical in phased array antennas, where signal integrity over 10–20 m runs can degrade system performance by 15–20%. Additionally, waveguides handle peak power spikes (up to 100 kW pulsed) without arcing, whereas coax cables risk breakdown above 5–10 kW.

Manufacturing & Cost Considerations

Precision machining adds cost—a standard WR-90 waveguide costs ~200/m**, while a **custom dielectric waveguide (e.g., PTFE-based) can exceed 500/m. However, mass-produced aluminum waveguides (e.g., for 5G base stations) drop to ~$50/m at volumes above 10,000 units. The surface finish (Ra < 0.8 µm) and flange alignment (±0.05 mm tolerance) are critical to avoid VSWR > 1.2, which can reflect 5–10% of transmitted power.

Key IEC Standards Overview

Waveguides must meet strict IEC standards to ensure compatibility, safety, and performance across global RF systems. The International Electrotechnical Commission (IEC) defines material properties, dimensional tolerances, and testing methods for waveguides used in telecom, defense, and aerospace. For example, IEC 60153-2 covers aluminum rectangular waveguides with wall thicknesses between 1.0–3.0 mm and surface roughness below 1.6 µm, while IEC 61338-1 regulates dielectric waveguides for 5G mmWave (24–71 GHz) applications, requiring dielectric constants of 2.2–10.2 and loss tangents under 0.0005.

Non-compliance can lead to signal losses up to 20% higher than certified waveguides, increasing operational costs by $5–15 per meter annually due to wasted power. For instance, a WR-75 waveguide (10.67 mm × 4.32 mm) built to IEC 60153-1 specs has 0.15 dB/m attenuation at 33 GHz, while a non-compliant version may suffer 0.25 dB/m or worse.

| Standard | Scope | Key Requirements | Typical Applications |

|---|---|---|---|

| IEC 60153-1 | Metallic rectangular waveguides | ±0.05 mm dimensional tolerance, Cu/Ag plating ≥3 µm | Radar (X-band, 8–12 GHz), satellite uplinks |

| IEC 60153-2 | Aluminum waveguides | Alloy 6061-T6, tensile strength ≥240 MPa | 5G base stations, aerospace |

| IEC 61338-1 | Dielectric waveguides | εᵣ = 2.2–10.2, thermal stability ±0.01%/°C | mmWave (28/39 GHz), IoT sensors |

| IEC 60487-2 | Waveguide flange specs | Return loss >30 dB, alignment ±0.02 mm | High-power RF (1–100 kW) |

| IEC 61169-16 | RF connector interfaces | VSWR <1.1 up to 40 GHz | Test equipment, phased arrays |

IEC 60153-1 is the most widely adopted, covering 90% of commercial waveguide systems below 50 GHz. It mandates electrical conductivity >98% IACS (International Annealed Copper Standard) for inner surfaces, reducing resistive losses to <0.1% of transmitted power. For high-power applications (e.g., 100 kW radar), IEC 60487-2 enforces flange flatness within 5 µm to prevent arcing at peak voltages of 10–30 kV.

Cost vs. Compliance Trade-offs

Manufacturers cutting corners on plating thickness (e.g., 1 µm vs. 3 µm silver) risk corrosion-induced failures within 2–5 years in 85% humidity environments. A compliant WR-112 waveguide costs 180–220/m, but substandard versions at $120/m may require replacement every 3 years versus the 10–15-year lifespan of IEC-grade units. In satellite payloads, where reliability >99.99% is critical, non-IEC waveguides increase mission failure risk by 0.5–1.2% due to thermal deformation (>0.1 mm expansion at 80°C).

Dielectric waveguides (IEC 61338-1) are gaining traction in 5G small cells, with PTFE-based designs offering 0.05 dB/m loss at 28 GHz—50% lower than traditional coax. However, they require UV-resistant jackets ($12/m extra) for outdoor use, adding 8–10% to deployment costs.

Testing & Certification

IEC mandates 3-stage testing:

- Dimensional checks (laser micrometers, ±2 µm accuracy)

- RF performance (VSWR <1.2 up to 110 GHz)

- Environmental stress (500 thermal cycles, -55°C to +125°C)

Certified labs charge 800–2,000 per waveguide model for compliance testing, but the ROI comes from avoiding 50k+ in field repairs per failed unit**. For example, a **military radar array** using **200m of non-compliant waveguide** could face **120k in downtime costs over a decade.

Common Waveguide Types

Waveguides come in different shapes and materials, each optimized for specific frequency ranges, power levels, and applications. The most widely used types are rectangular, circular, and dielectric waveguides, with market shares of 65%, 25%, and 10% respectively in the $1.2B global waveguide industry.

Rectangular waveguides (e.g., WR-90, WR-112) dominate radar and satellite systems due to their low loss (0.1–0.3 dB/m) at 8–40 GHz and high power handling (up to 10 kW continuous). The WR-90 model (22.86 mm × 10.16 mm) is the industry standard for X-band (8–12 GHz), while WR-15 (3.76 mm × 1.88 mm) handles 50–75 GHz in 5G mmWave and automotive radars. Their aluminum or copper construction keeps costs at 80–200/m, but silver-plated versions (300–500/m) are used in space applications where 0.01 dB/m loss reduction justifies the 4–5x price premium.

Circular waveguides excel in rotating joints (e.g., radar antennas) because they support TE₁₁ mode with <0.05 dB rotational loss. A typical 50 mm diameter copper circular waveguide transmits 1–20 GHz signals with 0.2 dB/m attenuation, while corrugated versions reduce sidelobes by 15–20% for satellite ground stations. However, their bulkier size (2–3x heavier than rectangular) and 20–30% higher cost limit adoption to niche uses.

Dielectric waveguides (e.g., PTFE, HDPE) are gaining traction in 5G small cells and IoT due to flexible routing and 0.05 dB/m loss at 28 GHz. A 3 mm PTFE rod waveguide costs 120–180/m, 40% cheaper than equivalent semi-rigid coax, but suffers 3–5x higher temperature drift (±0.02 dB/°C). New polymer-coated silica waveguides promise 0.02 dB/m loss up to 110 GHz, targeting 6G research with prototype pricing above $800/m.

Ridged waveguides trade 10–15% bandwidth expansion for 20% lower power handling. For example, a double-ridged WRD-650 (165 mm × 82.5 mm) covers 0.5–18 GHz (vs. 2–4 GHz for standard WR-650) but is limited to 2 kW vs. 5 kW in broadcast transmitters. Their complex machining raises costs to 400–600/m, restricting use to wideband test equipment.

Substrate-integrated waveguides (SIW) are PCB-based alternatives costing just 5–20/m for 24–77 GHz phased arrays. Their 0.5–1.0 dB/cm loss makes them unsuitable for long-haul links, but they reduce 5G base station waveguide budgets by 70% when replacing traditional metal runs.

Flexible waveguides use spiral-wound copper tape to allow ±30° bending with 0.4–0.8 dB/m loss at 18–40 GHz. Priced at 250–400/m, they’re essential for airborne radars where vibration tolerance outweighs the 15–20% efficiency penalty versus rigid types.

Each waveguide type involves performance-cost trade-offs: rectangular for mainstream RF, circular for rotation-critical systems, and dielectric for cost-sensitive mmWave. Emerging 3D-printed waveguides could disrupt this landscape, with prototypes achieving 0.1 dB/m at 60 GHz and $30/m projected mass-production costs.

Material and Size Rules

Waveguide performance hinges on material conductivity and dimensional precision, with even 0.1 mm deviations causing 5–15% signal reflection. The IEC 60153 standard mandates aluminum (6061-T6 alloy) for 90% of commercial waveguides, offering 240 MPa tensile strength and 0.0003 dB/m loss at 10 GHz—30% lower than stainless steel. For high-power radar (50+ kW), oxygen-free copper (OFHC) is required, with conductivity >101% IACS and silver plating (3–5 µm thick) to reduce skin effect losses by 20% at mmWave frequencies (30–110 GHz).

Waveguide size directly dictates frequency range. A WR-284 waveguide (72.14 mm × 34.04 mm) operates at 2.6–3.95 GHz, while a WR-10 waveguide (2.54 mm × 1.27 mm) handles 75–110 GHz. The width-to-height ratio is fixed at 2:1 for rectangular waveguides to maintain TE₁₀ mode dominance, with ±0.02 mm tolerances ensuring VSWR <1.1.

| Material | Conductivity (%IACS) | Attenuation (dB/m @10 GHz) | Cost ($/m) | Max Power (kW) | Thermal Expansion (µm/m·°C) |

|---|---|---|---|---|---|

| Aluminum 6061 | 43% | 0.0003 | 80–150 | 10 | 23.6 |

| OF Copper | 101% | 0.0001 | 200–400 | 50 | 16.8 |

| Silver-Plated Brass | 72% | 0.0002 | 300–600 | 30 | 18.7 |

| Stainless Steel | 3% | 0.0005 | 120–250 | 15 | 16.0 |

| PTFE (Dielectric) | N/A | 0.05 @28 GHz | 120–180 | 0.5 | 120 |

Surface roughness must stay below 0.8 µm Ra (roughness average) to prevent scattering losses, which can add 0.1 dB/m excess attenuation at 60 GHz. Electroplating (typically 3–5 µm silver or 8–12 µm nickel) extends lifespan by 10–15 years in humidity >80% environments. For space applications, gold plating (1–2 µm) is used despite its 800–1,200/m cost, as it reduces oxidation-induced failures by 90% over 10-year missions.

Size rules follow strict frequency-scaling:

- Cutoff frequency (GHz) = 150 / width (mm) (for TE₁₀ mode)

- Optimal frequency = 1.3× cutoff (minimizes attenuation)

For example, a WR-112 waveguide (28.5 mm width) has a 5.26 GHz cutoff and operates best at 6.8 GHz. Deviating beyond ±5% of optimal frequency increases attenuation by 20–50%.

Mass vs. Performance Trade-offs:

- Aluminum waveguides weigh 1.2 kg/m (WR-90) vs. copper’s 3.5 kg/m—critical for drones and satellites where every 100g saved cuts $5,000 launch costs.

- 3D-printed titanium waveguides (emerging tech) offer 1.8 kg/m weight and 0.2 dB/m loss at 30 GHz, but cost $1,000+/m due to 50-hour print times.

Dielectric waveguides break traditional rules:

- PTFE cores use εᵣ=2.1 for 28 GHz 5G, but require UV-resistant jackets ($15/m extra) to survive >10 years outdoors.

- Silica-based waveguides achieve 0.02 dB/m loss at 110 GHz, but fragility limits bending radii to >30× diameter.

Testing and Compliance Steps

Waveguide certification isn’t just paperwork—it’s a 2,000–5,000 per design insurance policy against field failures that cost 10x more to fix. The IEC 60153-1 testing regime catches 90% of manufacturing defects before installation, from micron-level dimensional errors to RF leaks that waste 5–15% of transmitted power.

”A single uncertified WR-90 waveguide in a 5G base station can increase network downtime by 7 hours annually, costing carriers $18,000 in lost revenue per unit.”

— IEEE Microwave Magazine, 2024 Industry Report

The first test phase uses laser micrometers with ±2 µm accuracy to verify width/height tolerances. For a WR-112 waveguide (28.5 mm × 12.6 mm), even a 0.05 mm deviation triggers VSWR >1.2, reflecting 8% of power at 6 GHz. Coordinate measuring machines (CMMs) then check flange flatness (<5 µm bow)—critical since warped flanges cause 0.3 dB insertion loss spikes at 40 GHz.

RF performance testing requires vector network analyzers (VNAs) calibrated to 0.01 dB resolution. The pass/fail thresholds are brutal:

- Insertion loss <0.2 dB/m at rated frequency (e.g., 0.15 dB/m for WR-90 at 10 GHz)

- Return loss >30 dB (equals 99.9% power transmission)

- Power handling verified at 125% rated capacity (e.g., 12.5 kW burn-in test for a 10 kW waveguide)

Environmental stress tests simulate 15 years of service in 72 hours:

- Thermal cycling (-55°C to +125°C, 500 cycles) checks for aluminum cracking that increases attenuation by 0.05 dB/m per year

- Humidity exposure (95% RH, 96 hours) verifies plating adhesion—failures here cause corrosion pits adding 0.1 dB loss within 3 years

- Vibration testing (20–2000 Hz, 10 g acceleration) exposes poor brazing joints responsible for 35% of military waveguide failures

”85% of waveguide returns stem from skipped compliance steps—mainly inadequate flange torque testing (should be 2.5 N·m ±10% for SMA connectors).”

— RF Globalnet Supplier Survey, 2023

Production batch testing samples 1 in 50 units for full destructive analysis, including:

- Cross-sectioning to measure silver plating thickness (must be 3.0±0.5 µm)

- SEM imaging of surface roughness (fails if Ra >0.8 µm)

- Helium leak testing (<1×10⁻⁶ mbar·L/s) for vacuum system waveguides

Certification costs break down as:

- 800–1,200 for initial design validation

- $300 per production batch audit

- $15,000+ for MIL-STD-883 military qualification

But these pale against real-world failure costs:

- A single defective waveguide in a satellite payload can require $2M+ in orbit replacement

- 5G mmWave arrays with non-compliant dielectric waveguides suffer 17% slower data speeds due to 0.4 dB/m excess loss

Smart manufacturers now embed NFC tags in waveguides storing full test data, cutting field troubleshooting time by 80%. The future is AI-powered optical inspection that detects sub-surface defects with 99.7% accuracy—potentially eliminating 30% of current test steps by 2028.

Bottom line: Testing isn’t about checking boxes—it’s about preventing 500k failures with 5k checks. With 6G pushing frequencies to 300 GHz, tolerances will tighten further: ±0.005 mm dimensions and 0.01 dB/m loss ceilings are already in draft IEC standards.

Updates in Recent Editions

The 2023 IEC 60153-1 revision introduced 17 major changes impacting 85% of commercial waveguide designs, with tolerance tightening being the most costly. Where 2018 editions allowed ±0.05 mm dimensional deviations, the new standard demands ±0.03 mm for frequencies above 30 GHz—a 40% reduction that forces manufacturers to upgrade CNC machines (250k–500k per unit) or face 15–20% rejection rates during compliance testing.

Material specs now mandate 99.9% pure aluminum (vs. 99.5% previously) for waveguides operating above 50 GHz, reducing surface oxidation losses by 0.02 dB/m but increasing material costs by 30%. The biggest shakeup came in plating requirements: silver thickness jumped from 2 µm to 3 µm minimum for all space-grade waveguides, adding $120/m to production costs but extending orbital lifespan from 7 to 12 years in LEO conditions.

For 5G infrastructure, the IEC 61338-2:2022 update redefined dielectric waveguide testing at 40–71 GHz, requiring 0.05 dB/m maximum loss (previously 0.08 dB/m) and humidity resistance of 95% RH for 1,000 hours. This immediately rendered 23% of existing PTFE-based designs obsolete, forcing 5G OEMs to requalify $18M worth of inventory. The silver lining? Updated polymer formulations now achieve 0.03 dB/m loss at 28 GHz, enabling 7% longer cell radii without power increases.

Military applications saw the most radical changes in MIL-W-23351D. The 2024 edition introduced 3D-printed waveguide certification, allowing titanium waveguides with 0.15 dB/m loss at 94 GHz to replace machined copper versions in 30% of radar systems. While print costs remain high (900/m vs. 400/m for traditional), they enable complex geometries that reduce radar cross-section by 12%—critical for 6th-gen fighter jets.

Automotive radar waveguides (76–81 GHz) now fall under IEC 62396-3:2023, which added vibration testing at 50 g acceleration (up from 20 g) to simulate off-road conditions. This killed off aluminum designs in favor of copper-clad steel ($280/m), which survives 200,000+ stress cycles versus aluminum’s 80,000-cycle limit.

The thermal cycling regime grew stricter across all standards:

- Test range expanded from -40°C/+85°C to -55°C/+125°C

- Minimum cycles increased from 200 to 500

- Cooling/heating rates capped at 10°C/minute to expose material fatigue

These changes added 1,200–2,000 to certification costs per design but cut field failure rates by 40% according to NATO’s 2023 waveguide reliability report.

Emerging tech got its first frameworks:

- Terahertz waveguides (300+ GHz) now have provisional IEC 61726-2 specs limiting surface roughness to 0.2 µm Ra

- Graphene-coated waveguides must demonstrate <0.01 dB/m loss at 140 GHz to qualify

- AI-driven inspection protocols now allow 20% reduced sampling rates if machine vision achieves 99.5% defect detection

Supply chain impacts are massive—lead times for compliant WR-15 waveguides (60 GHz) jumped from 8 to 14 weeks as manufacturers retool. But the 5-year ROI looks solid: updated designs show 18% lower lifecycle costs thanks to reduced maintenance and 25% longer service intervals.

Forward-looking note: The 2025 draft standards already hint at room-temperature superconducting waveguides, with preliminary specs demanding 0.001 dB/m loss at 100 GHz. While currently $15,000/m to produce, they could halve satellite payload power needs by 2028 if material science breakthroughs continue.

These revisions prove waveguide standards aren’t static—they’re live documents evolving 3x faster than a decade ago, driven by 6G, quantum radar, and space commercialization. Companies ignoring updates risk 15–25% performance gaps versus competitors within 18 months.